“Customers have asked us to allow HCSS Aerial measurements and quantities data to be integrated with HCSS HeavyJob Project Management and Job Cost solution,” said JP Giometti, vice president, Global Strategy and Corporate Development, HCSS. “We are Beta testing this integration and gathering feedback from clients before introduction. By integrating with HeavyJob, clients will be able to keep their jobs and budget on track with less expensive yet more accurate drone mapping.”

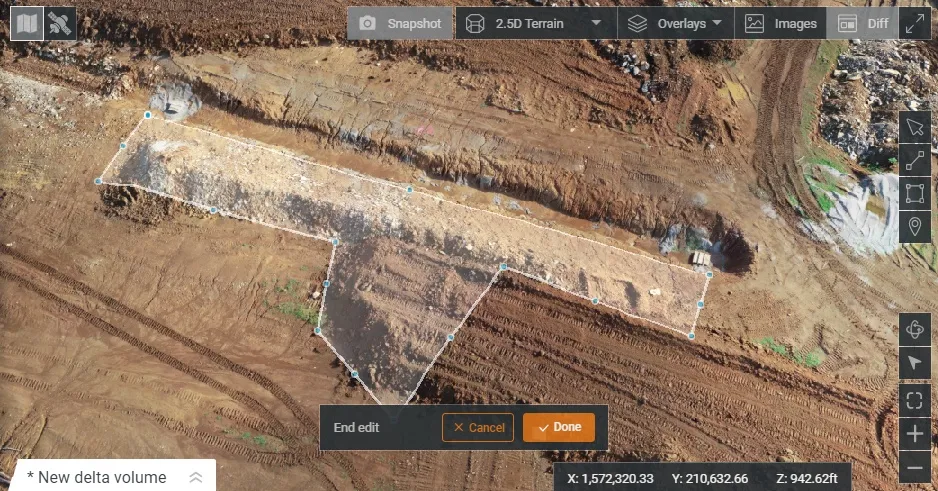

Features in the new update include the ability to provide measurements and analytics from design items, saving time, whether users are running calculations to compare design to the as-built for quality assurance or checking bills from subcontractors. The package can also eliminate any errors that might occur from manual drawing areas or lines. It can import images into HCSS Aerial to create a new annotation. The platform pins the annotation automatically, depending on the GPS position. Users inspecting a site on a tablet can import the photographs on the go. It offers easier drawing of lines and polygons for measurements and analytics.

Users can now make edits and adjust points in lines and polygons without starting calculations. The package can upload design files and notes before the first flight or while the flight is still being processed. A “Go to Coordinates” navigation tool can change a map display to a specific point by entering coordinates.

Measurement details for tablets optimises the small screen and allows users to choose between side navigation and a top-mounted calculation detail box.