Machines from CIFA are playing an important role in providing protection during a port expansion job. There is a considerable need for additional sea protection during a major port expansion project in Italy. The port of Civitavecchia is being expanded as part of a programme to boost its capacity and capabilities and develop the facility both for its commercial and tourist operations.

However, the work comes with considerable need to improve the protection from the sea, so as to ensure that its roadways

August 19, 2015

Read time: 2 mins

Machines from 2203 CIFA are playing an important role in providing protection during a port expansion job. There is a considerable need for additional sea protection during a major port expansion project in Italy. The port of Civitavecchia is being expanded as part of a programme to boost its capacity and capabilities and develop the facility both for its commercial and tourist operations.

However, the work comes with considerable need to improve the protection from the sea, so as to ensure that its roadways and other infrastructure do not fall victim to any inrush during periods of bad weather.

The client is the Civitavecchia Port Authority of the same name, while the large cell caissons made in reinforced concrete are being carried out by3869 Grandi Lavori Fincosit and Impresa Pietro Cidonio.

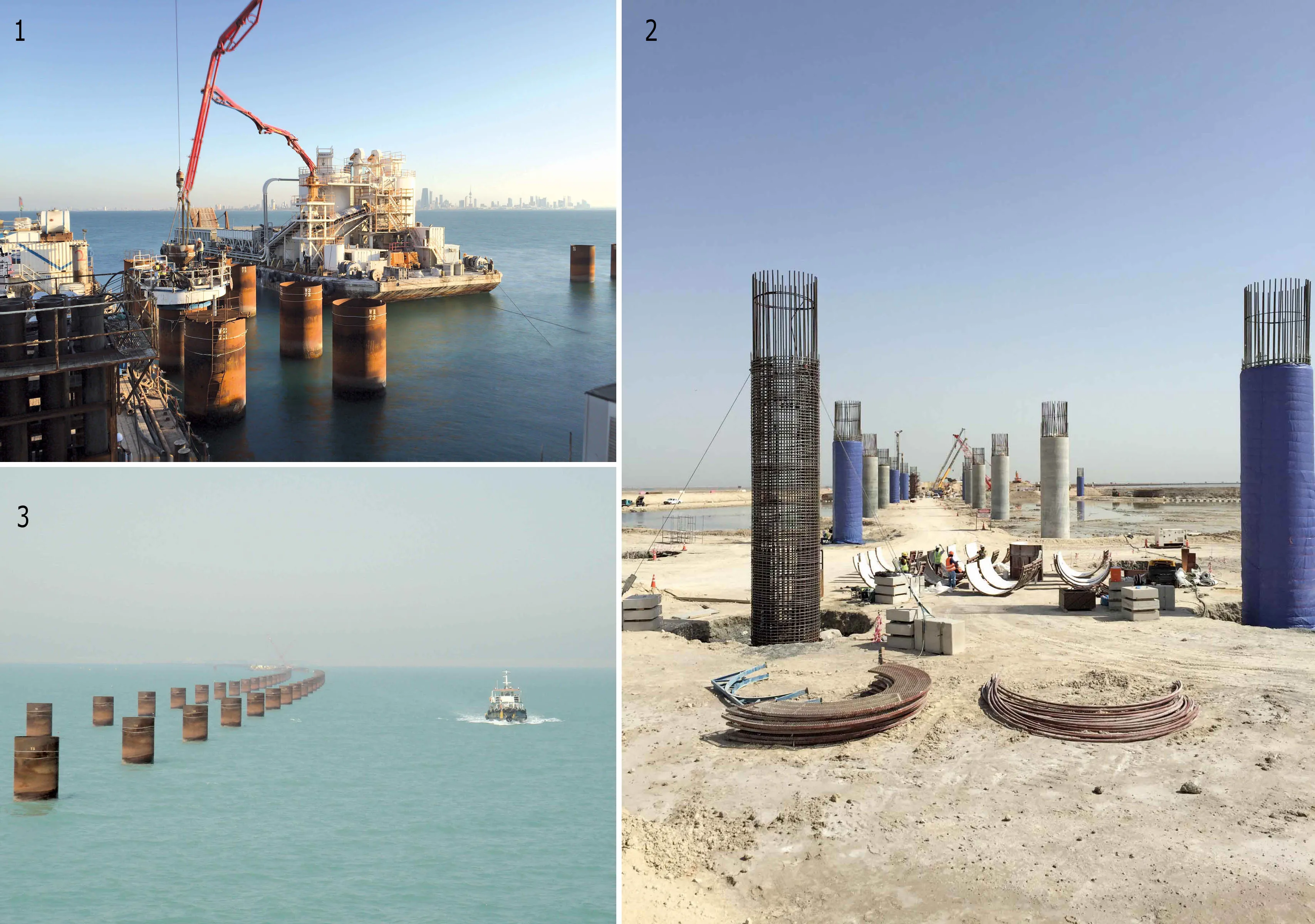

A Cifa K48 concrete pump is carrying out key tasks in casting concrete to make cell caissons. These reinforced concrete structures comprise a bottom slab that serves as the foundations, and an integral shaft, consisting of perimeter walls and internal sections that divide it into an adequate number of cells.

The formwork is made of double metal formwork and a work surface. First, the metal reinforcement for the slab is laid down with a rebar for the external walls and internal partitions for the trunk of the caisson, then the base slab is cast, delimited by special formwork perimeters. When the sliding formwork is lowered, the caisson shaft is built by casting the concrete into the formwork and simultaneously installing the metal warping. After the shaft is cast, the formwork is suspended above the upper mobile frame and raised so as not to hinder the launching of the caisson. Lastly, the box, suitably ballasted, is extracted from the system and towed to the point of temporary storage in flotation, where installation is completed and the prefabricated cover slab is sealed.

However, the work comes with considerable need to improve the protection from the sea, so as to ensure that its roadways and other infrastructure do not fall victim to any inrush during periods of bad weather.

The client is the Civitavecchia Port Authority of the same name, while the large cell caissons made in reinforced concrete are being carried out by

A Cifa K48 concrete pump is carrying out key tasks in casting concrete to make cell caissons. These reinforced concrete structures comprise a bottom slab that serves as the foundations, and an integral shaft, consisting of perimeter walls and internal sections that divide it into an adequate number of cells.

The formwork is made of double metal formwork and a work surface. First, the metal reinforcement for the slab is laid down with a rebar for the external walls and internal partitions for the trunk of the caisson, then the base slab is cast, delimited by special formwork perimeters. When the sliding formwork is lowered, the caisson shaft is built by casting the concrete into the formwork and simultaneously installing the metal warping. After the shaft is cast, the formwork is suspended above the upper mobile frame and raised so as not to hinder the launching of the caisson. Lastly, the box, suitably ballasted, is extracted from the system and towed to the point of temporary storage in flotation, where installation is completed and the prefabricated cover slab is sealed.