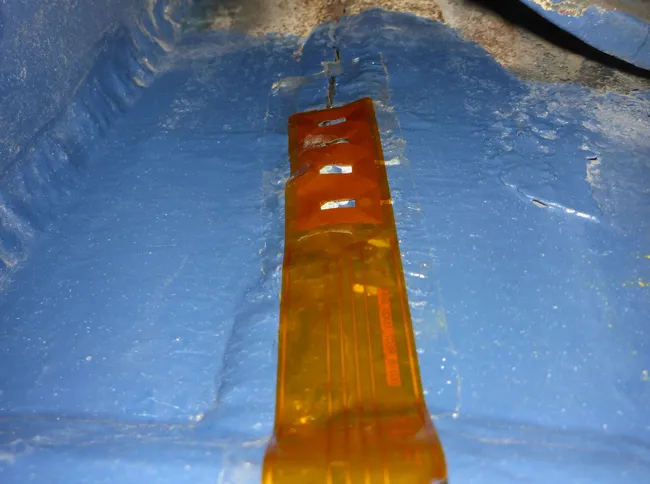

The new SGS AIMSight structural health monitoring solution provides continuous, real time monitoring of the health of critical assets to a higher level of precision than conventional SHM systems and structural inspection schemes. This serves as an early warning system, so asset owners can anticipate and schedule onsite inspections and maintenance work, and respond to defects before they have a serious impact on their operation or finances. SGS AIMSight is scalable, allowing it to be deployed on critical parts of the structure at first and extended as required.

Over and above the crack monitoring sensors, which are attached to the asset and collect specific data on defects, additional parameters are also captured, such as local temperature and acceleration, which enables root cause analysis of the defects’ behaviour– which provides invaluable information to the engineers devising the right maintenance solution. The data platform is extensible, and can handle and integrate all types of data, irrespective of the source, including past visual inspection reports, and can generate high-value analytics to be integrated into monitoring reports.