The bold decision to go against the norm and build the back spans using falsework for the Ironton-Russell replacement bridge between Parkersburg, Kentucky and Cincinnati, Ohio allowed land access to build the main span which, along with the first use in the U.S. of precast stay anchor blocks, meant the new structure could get built.

January 24, 2014

Read time: 3 mins

The bold decision to go against the norm and build the back spans using falsework for the Ironton-Russell replacement bridge between Parkersburg, Kentucky and Cincinnati, Ohio allowed land access to build the main Span which, along with the first use in the US of precast stay anchor blocks, meant the new structure could get built.

5978 Brayman Construction Corporation’s project works bid, utilising a combination of Brayman and 5979 Finley Engineering Group’s design and construction method changes, was 4% below Ohio State’s final cost estimate of US$84.6 million.

When Rich Blankenship became the mayor of the city of Ironton, he made it a priority to get this critical infrastructure project under way by working diligently with the Ohio Department of Transportation (ODOT), former Governor Ted Strickland, and current Ohio Governor John R. Kasich.

Opened in 1922, the original Ironton-Russell Bridge was the first highway bridge along the Ohio River between Parkersburg and Cincinnati. The cantilever bridge was retrofitted in 1970s, and later posted with restrictions, having become inefficient for today’s traffic and economically impractical to maintain. In 2000, ODOT recommended full replacement.

URS was selected in January 2006 to redesign the replacement bridge after ODOT rejected the bids of the initial single-tower, two-Span cable-stayed design, which came in well over construction estimates.

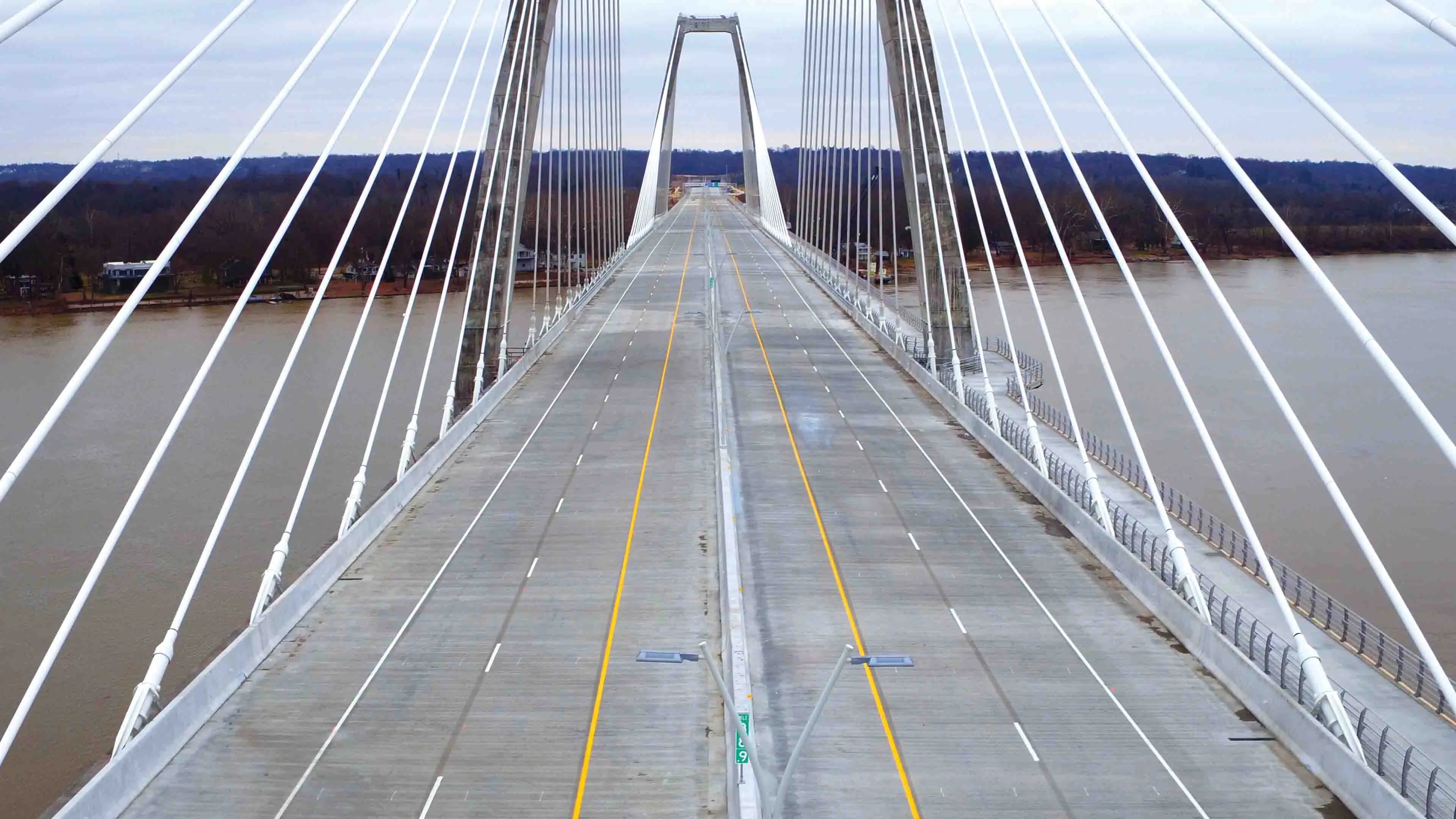

The new cable-stayed replacement bridge is a three-Span, two-tower design with two 3.65m travel lanes. The 797.35m long bridge is comprised of a 274.32m cable-stayed main Span and two 112.77m cable-stayed side spans, two 96.01m tall towers and two anchor piers on the river’s edge. The entire structure is cast-in-place with reinforced concrete featuring 2,630tonnes of rebar, utilising the cable stays to construct the bridge by the balanced cantilever methodology. Foundation units consist of 53 large-diameter drilled shafts ranging in size from 1.06m to 2.43m.

ODOT asked URS to oversee the revised portions of the design and construction that the Brayman-Finley team proposed. “The changes uphold the integrity of the original design, and, since some members were designed to support heavy construction equipment, the bridge has more robust side spans,” said Steve Stroh, URS’ project manager.

“Our early collaboration with Finley and VSL enabled us to work out alternative construction sequence solutions that ultimately saved ODOT $15.2 million over the next closest bidder,” said Stephen M. Muck, Brayman’s CEO.

Craig Finley Jr, managing principal of Finley, said, “The falsework was designed as a modular system, allowing it to be used for both the Kentucky and Ohio approaches and reducing the number of travellers from two to one."

When Rich Blankenship became the mayor of the city of Ironton, he made it a priority to get this critical infrastructure project under way by working diligently with the Ohio Department of Transportation (ODOT), former Governor Ted Strickland, and current Ohio Governor John R. Kasich.

Opened in 1922, the original Ironton-Russell Bridge was the first highway bridge along the Ohio River between Parkersburg and Cincinnati. The cantilever bridge was retrofitted in 1970s, and later posted with restrictions, having become inefficient for today’s traffic and economically impractical to maintain. In 2000, ODOT recommended full replacement.

URS was selected in January 2006 to redesign the replacement bridge after ODOT rejected the bids of the initial single-tower, two-Span cable-stayed design, which came in well over construction estimates.

The new cable-stayed replacement bridge is a three-Span, two-tower design with two 3.65m travel lanes. The 797.35m long bridge is comprised of a 274.32m cable-stayed main Span and two 112.77m cable-stayed side spans, two 96.01m tall towers and two anchor piers on the river’s edge. The entire structure is cast-in-place with reinforced concrete featuring 2,630tonnes of rebar, utilising the cable stays to construct the bridge by the balanced cantilever methodology. Foundation units consist of 53 large-diameter drilled shafts ranging in size from 1.06m to 2.43m.

ODOT asked URS to oversee the revised portions of the design and construction that the Brayman-Finley team proposed. “The changes uphold the integrity of the original design, and, since some members were designed to support heavy construction equipment, the bridge has more robust side spans,” said Steve Stroh, URS’ project manager.

“Our early collaboration with Finley and VSL enabled us to work out alternative construction sequence solutions that ultimately saved ODOT $15.2 million over the next closest bidder,” said Stephen M. Muck, Brayman’s CEO.

Craig Finley Jr, managing principal of Finley, said, “The falsework was designed as a modular system, allowing it to be used for both the Kentucky and Ohio approaches and reducing the number of travellers from two to one."