RMD Kwikform has supplied the Abigroup with a full range of formwork, shoring and edge protection equipment for all 25 bridges on the Kurri Kurri to Branxton section of the Hunter Expressway in New South Wales

(NSW) Australia.

July 1, 2013

Read time: 2 mins

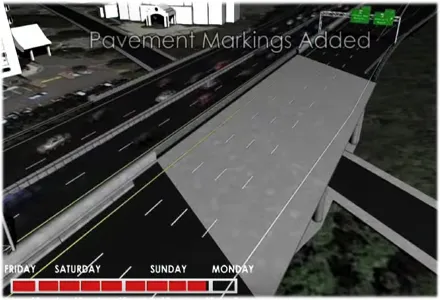

The Hunter Expressway is a US$1.7billion, 40km four-lane freeway link between the F3 Freeway near Seahampton, and the New England Highway, west of Branxton. Abigroup opted to utilise a range of RMD Australia equipment solutions for the bridge sections of the expressway, to minimise the footprint of clearing and disturbance while working near tracts of native vegetation, which provide habitats for threatened flora and fauna.

Of the project Mark Stanley, sales representative from RMD Australia, said: “We supplied a wide range of equipment to this large scale project, including innovative edge protection, access solutions, bridge abutment formwork, shoring systems, pier and headstock shoring and access equipment. We also included four cast in-situ voided bridge decks and four large spans of Paraslim composite bridge system for the bridge cantilevers.”

The formwork and shoring solutions developed for the cast in-situ structures along the Hunter Expressway were designed to cope with the changing circumstances at the sites structures, which initially slowed progress. RMD Australia developed the best method of forming these varying structures, which ensured the de_ ned budget and schedule for the project was achievable.

“Primarily we have supplied 400tonnes of Rapidshor, 100tonnes of Superslims and Alform Beam plus 100tonnes of Superslim and Alform Beam Headstock and solutions,” said Stanley. “The equipment has been designed around a number of intricate, complex structures, one of which utilises 60tonnes of the RMD Australia Paraslim system for a large span rail bridge.”

The Hunter Expressway is expected to significantly improve the efficiency of the national road network in Australia, providing a major new arterial route between Newcastle and the Upper Hunter Valley. Despite the challenges posed by working in areas subject to mine subsidence and acid sulphate soils, Abigroup is said to have been able to utilise the systems supplied by RMD Australia to progress on schedule.

Work on the Hunter Expressway is expected to be completed at the end of 2013.