Construction of the Fehmarn Belt Fixed Link between Denmark and Germany should start this autumn for completion in 2028, according to the Danish government.

Danish company

An autumn start would mean the link is opened on schedule, said Ole Birk Olesen, Denmark’s minister for transport, building and housing. This would also help to improve the possibility of securing the allocated

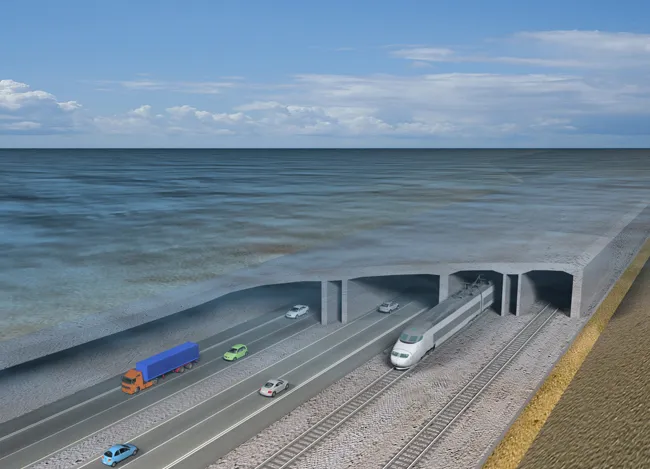

The Fehmarn Belt is a strait between the German island of Fehmarn and the Danish island of Lolland. The tunnel will replace a ferry service from Rødby and Puttgarden. The project’s approval process had been bogged down over environmental issues, especially within the German state of Schleswig-Holstein in which the southern end of 18km immersed tunnel will surface.

A Rambøll-Arup-TEC consultancy joint venture is engaged in a client consultancy services contract with Fmern. The joint venture has also worked on other landmark infrastructure projects, including the Øresund Tunnel in Denmark, the City Tunnel in Malmö, Sweden, the Medway Tunnel in England, as well as underground rail systems in Amsterdam and Copenhagen.

COWI is carrying out the detailed design of the tunnel (north tunnel section, south tunnel section, and ramps & portals). Meanwhile,

A second framework contract, for technical support services to Femern, is being carried out by ÅF-Hansen & Henneberg.

Project information is available on the project’s official website, %$Linker: