A key role in this work has been taken by the firm Cleveland Bridge UK. As part of

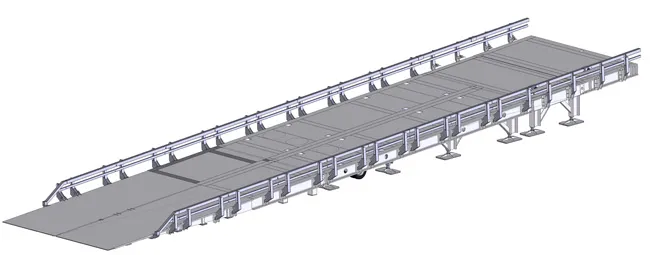

Containing 6,000tonnes of steel and comprising 76 separate main girders and 800 cross girders, the structure was fabricated at Cleveland Bridge’s production facility in Darlington, County Durham before component parts were transported to site by road over a period of months. The majority of the main girders are 40m long, 2m deep and weigh 50tonnes.

The section of the bridge crossing the river has the longest span, so a complex series of girders has been installed to carry the weight of the greater load.

To enable the installation of the structure, including the most recent viaduct sections, a temporary platform was constructed under the length of the new bridge to provide a solid base for cranes and lorries.

However, to reduce time and site congestion, Cleveland Bridge utilised a 600tonne capacity crawler crane for the installation, which could lift all components for each section of the bridge from a single position at the side of the bridge. This meant fewer crane movements and no need to move the crane across the bridge footprint.

Chris Droogan, managing director of Cleveland Bridge UK, said: “The River Great Ouse viaduct is a showpiece element of the A14 project and is worthy of its place as one of Cleveland Bridge’s most significant structures in our history.”

“The viaduct will have a major impact on improving this part of the UK road network and we are very proud to have played a part in its development.”