Judges described the bridge, designed by

"Everyone involved with the design and construction the Mersey Gateway Bridge over the past six years knows that this is an incredibly special structure,” said Paul Sanders, Cowi’s project director for the design joint venture. “But to have this officially recognised with such a prestigious award from IABSE, especially given the fierce competition from around the globe, is incredible.”

The UK project came ahead of the widening of the bridge over the Rande Strait in Spain and the Mukogawa Bridge in Japan.

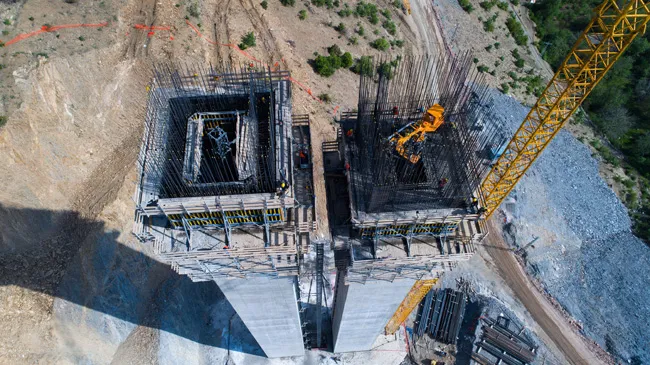

The Mersey Gateway is a 2.25km-long three-tower cable-stayed bridge with pylons up to 125m high and a 1km-long cable supported main span. The main bridge deck is constructed from pre-stressed and reinforced concrete suspended from the pylons by high strength steel cable stays.

The decks of the approach viaducts were constructed using two 1,700-tonne, 157m-long self-propelled launching gantries - movable scaffolding systems - enabling rapid construction of a complete 70m-long span in a single pour. On the cable-stayed bridge, six smaller gantries - form travellers - were used to cast the deck in 6m-long segments in a typical cycle of just five days.

The bridge was opened in June 2018 after three and a half years of construction - on time and under budget.

In Spain, the 400m-span cable-stay Rande Bridge spans the Rande Strait near Vigo Bay to link the municipalities of Redondela and Moaña. It was opened to traffic in 1981. But by 2006, average daily traffic on the bridge was 55,000 vehicles, close to its capacity and with resulting frequent traffic congestion.

Type of structure: Widening of a cable-stayed bridge

Date of completion: December, 2017

Location: Rande Strait, Spain

Owner: Ministerio de Fomento (Spanish Road Authority)

Concessionaire: Autopistas del Atlántico, C.E.S.A.

Structural Design: MC2 Estudio de Ingenieria S.L. and Dr.Manuel Juliá Vilardell

General Contractor: JV Dragados + Grupo Puentes

To increase capacity, several alternatives were studied. Taken into account the technical, aesthetic and economic aspects, the most favourable was a widening project consisting of two new external decks positioned along both the outer sides of the existing deck next to the main piers. This allowed bridge-widening work without either interrupting traffic on the bridge or disturbing the sensitive estuary environment.

Japan’s Mukogawa Bridge is the first structure in the world combining the butterfly web and the extradosed structure. This led to a significant reduction in the total weight of the superstructure and substructure, as well as reduction in environmental impact, according to the judges. It also increased seismic resistance by reducing the weight of the superstructure by 20%.

Type of structure: Extradosed bridge with butterfly webs

Date of completion: February, 2017

Location: Kobe city, Hyogo Prefecture, Japan

Owner: West Nippon Expressway Company Ltd.

Structural Design: Sumitomo Mitsui Construction

Contractor: Sumitomo Mitsui Construction

Architect: Sumitomo Mitsui Construction

Butterfly webs allow easy inspection and maintenance. Because of a shortage of skilled workers in Japan, precast concrete technology was employed to save on labour requirements.

The Mukogawa Bridge is also highly durable with reduced maintenance costs because of high-strength fibre reinforced concrete for the main girder webs. This required no steel reinforcement and also by protection of the external surfaces of the piers with the prefabricated precast members. The bridge stands out for its innovative use of butterfly webs and steel plate for the stay cable anchorages at the top, the judges noted.

*The IABSE Outstanding Structure Award, set up in 1998, recognises some of the most innovative and stimulating bridges around the world. Sustainability and respect for the environment are also important factors that the judges consider when making their decision.