The final steel beam has been installed for the replacement Port of Long Beach bridge - California’s first cable-stayed bridge for vehicles.

The beam was carefully lifted into position almost two years after construction began and which is expected to open later this year. The US$1.47 billion project to replace the current Gerald Desmond Bridge was started in 2013. The current bridge, finished in 1968, is a through arch steel structure that carries four lanes of Ocean Boulevard from Interstate 710 in Long Beach,

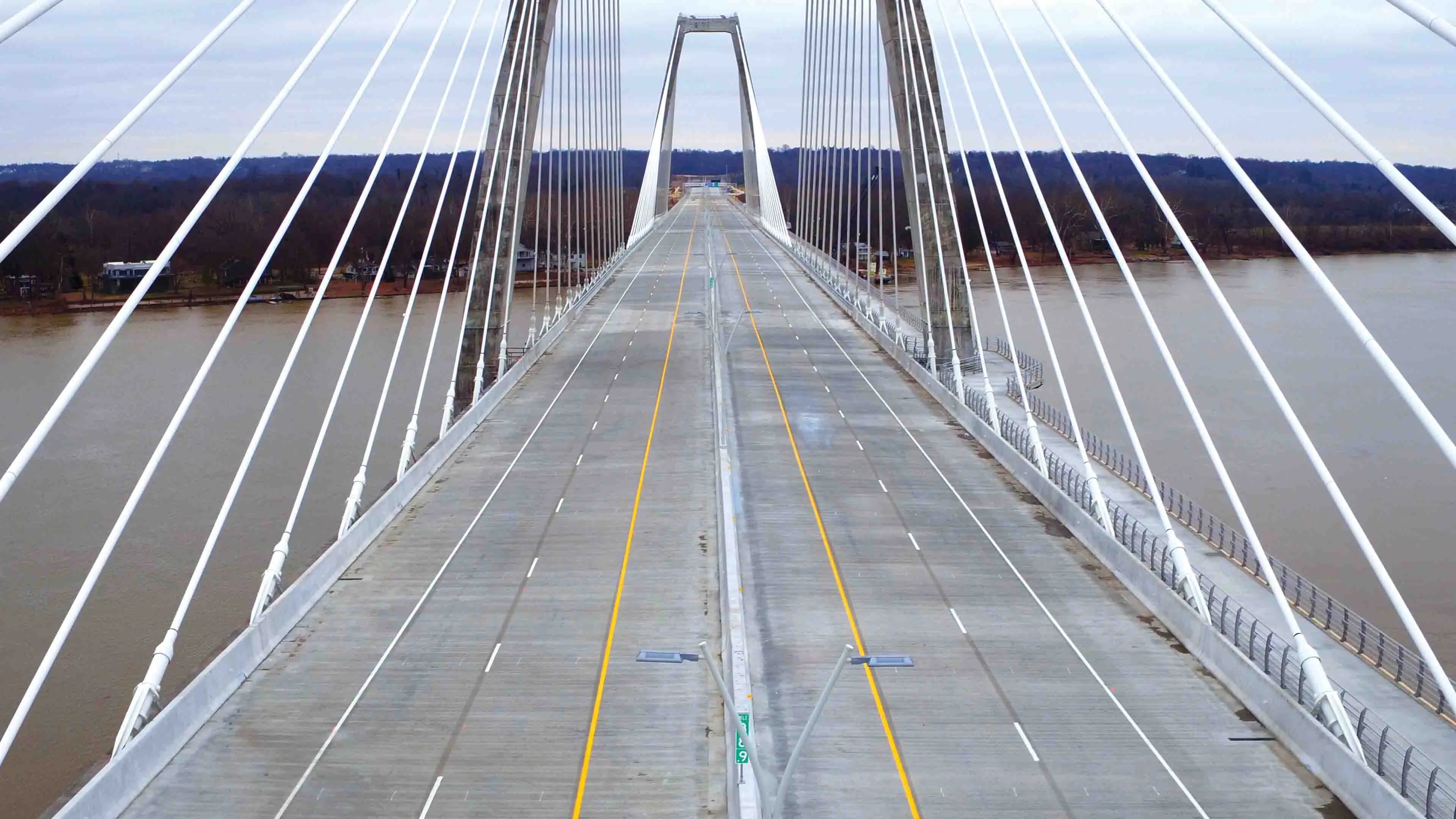

The new bridge will provide a higher clearance for cargo ships, possess a high degree of structural resilience against earthquakes and have a 100-year minimum lifespan. There will be six traffic lanes and four emergency shoulders, a bike and pedestrian path with scenic overlooks and more efficient transition ramps and connectors to improve traffic flow.

Assembling the main span over the Port’s Back Channel began in April 2018 with the lifting of the initial bolted sections of steel flooring to be attached to the first set of cables from the two 515-foot-tall towers.

Main-span construction requires deck sections to be added equally on both sides of the towers. Each floor beam is about 140 feet long and 10 feet tall, weighs about 32 tons and is connected to other steel components known as edge girders with more than 200 bolts.

Once a section of floor beams is bolted together, crews attach it to the tower with dozens of cables, then place pre-cast concrete road deck panels that form the road deck. There are 117 floor beams that support a main span that rises 205 feet over the water.

Additional major tasks left to do include a post-tensioning process by which cables are installed horizontally through the floor and pulled tight to increase the strength of the main span concrete deck.

The project is a joint effort by Caltrans – the California Department of Transportation - and the Port of Long Beach, with additional funding from the US Department of Transportation and the Los Angeles County Metropolitan Transportation Authority.