In the UK the Lanes Group is carrying out the contract to build specialist drainage for the New Wear Bridge in Sunderland. The Lanes Group will carry out this work for the joint venture partners building the new bridge link.

January 21, 2016

Read time: 2 mins

RSSIn the UK the 7891 Lanes Group is carrying out the contract to build specialist drainage for the New Wear Bridge in Sunderland. The Lanes Group will carry out this work for the joint venture partners building the new bridge link.

Personnel based at the Lanes depot in Newcastle have begun carrying out drainage work for the €152.7 million (£117.6 million) bridge project. This is the second major bridge building project Lanes Group has been contracted to work on in recent months. The company is also providing specialist drainage support for the Mersey Gateway Project, the new bridge spanning the River Mersey between Runcorn and Widnes.

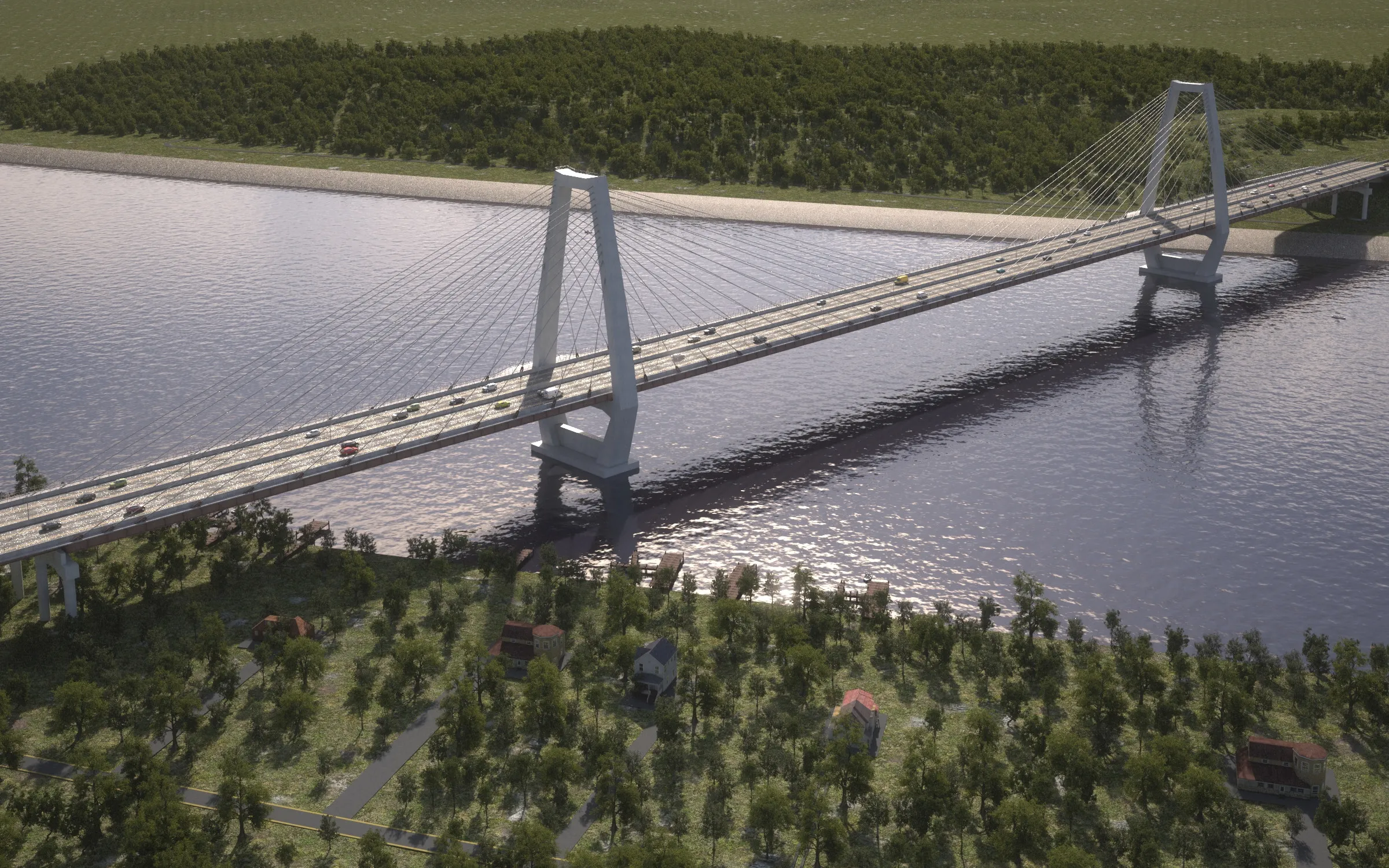

The New Wear Bridge is being built across the River Wear between the districts of Wessington and Pallion, and is designed to improve transport links between Sunderland city centre, the Port of Sunderland, the A19 and the wider region.

The three-span cable stay bridge, which is due to open in spring 2018, will also open up new development sites at either end. Lanes Group won a competitive tender to become the sole drainage contractor for the joint venture partners, Farrans Construction and Victor Buyck Steel Construction. Tasks already carried out by personnel from Lanes include desilting drainage pipes and carrying out CCTV drainage surveys.

The New Wear Bridge will be 336m long and will have a central A-frame cable pylon rising to 105m.

Personnel based at the Lanes depot in Newcastle have begun carrying out drainage work for the €152.7 million (£117.6 million) bridge project. This is the second major bridge building project Lanes Group has been contracted to work on in recent months. The company is also providing specialist drainage support for the Mersey Gateway Project, the new bridge spanning the River Mersey between Runcorn and Widnes.

The New Wear Bridge is being built across the River Wear between the districts of Wessington and Pallion, and is designed to improve transport links between Sunderland city centre, the Port of Sunderland, the A19 and the wider region.

The three-span cable stay bridge, which is due to open in spring 2018, will also open up new development sites at either end. Lanes Group won a competitive tender to become the sole drainage contractor for the joint venture partners, Farrans Construction and Victor Buyck Steel Construction. Tasks already carried out by personnel from Lanes include desilting drainage pipes and carrying out CCTV drainage surveys.

The New Wear Bridge will be 336m long and will have a central A-frame cable pylon rising to 105m.