Bertha, one of the world’s largest tunnelling machines will resume work underneath the US city of Seattle in November, nearly two years after breaking down.

Bertha, at 17.4m diameter, began her journey in July 2013. She was boring a path to relocate a 3.2km stretch of the elevated State Route 99 Alaskan Way Viaduct, built between 1949 and 1953 and which carries around 100,000 vehicles daily.

The elevated section will be moved underground allowing the creation of public space along Seattle’s downtown w

July 27, 2015

Read time: 3 mins

RSSBertha, one of the world’s largest tunnelling machines will resume work underneath the US city of Seattle in November, nearly two years after breaking down.

Bertha, at 17.4m diameter, began her journey in July 2013. She was boring a path to relocate a 3.2km stretch of the elevated State Route 99 Alaskan Way Viaduct, built between 1949 and 1953 and which carries around 100,000 vehicles daily.

The elevated section will be moved underground allowing the creation of public space along Seattle’s downtown waterfront. Options apart from a deep-bore tunnel included replacing it with a cut-and-cover tunnel, replacing it with another elevated highway or demolishing it and not replacing it.

But the construction schedule was severely disrupted in December 2013. After travelling around 305m, Bertha over heated and abruptly stopped. Contractor Seattle Tunnel Partners (STP) discovered damage to the machine’s seal system and contamination within the main bearing.

“Fully disassembling and assessing the machine was always the key to determining how long the repairs would take,” said Chris Dixon, STP project manager. “We want to reassemble the machine and resume tunnelling as quickly as possible, but we also want to ensure the repairs are done right.”

STP and233 Hitachi are responsible for the repair effort, including the machine’s schedule. While the machine has been under repair, STP said it has continued essential work at the future tunnel portals, including construction of ramp and highway connections and the buildings that will house tunnel operations.

“The contractor’s schedule has changed, but the contract that governs their work remains the same,” said914 Washington State Department of Transportation’s Todd Trepanier, the Alaskan Way Viaduct Replacement Programme administrator.

“The state is a paying customer in this transaction, and we’re intent on getting what we contracted for. We will continue to protect taxpayers and hold the contractor responsible for their work as they deliver this vital project.”

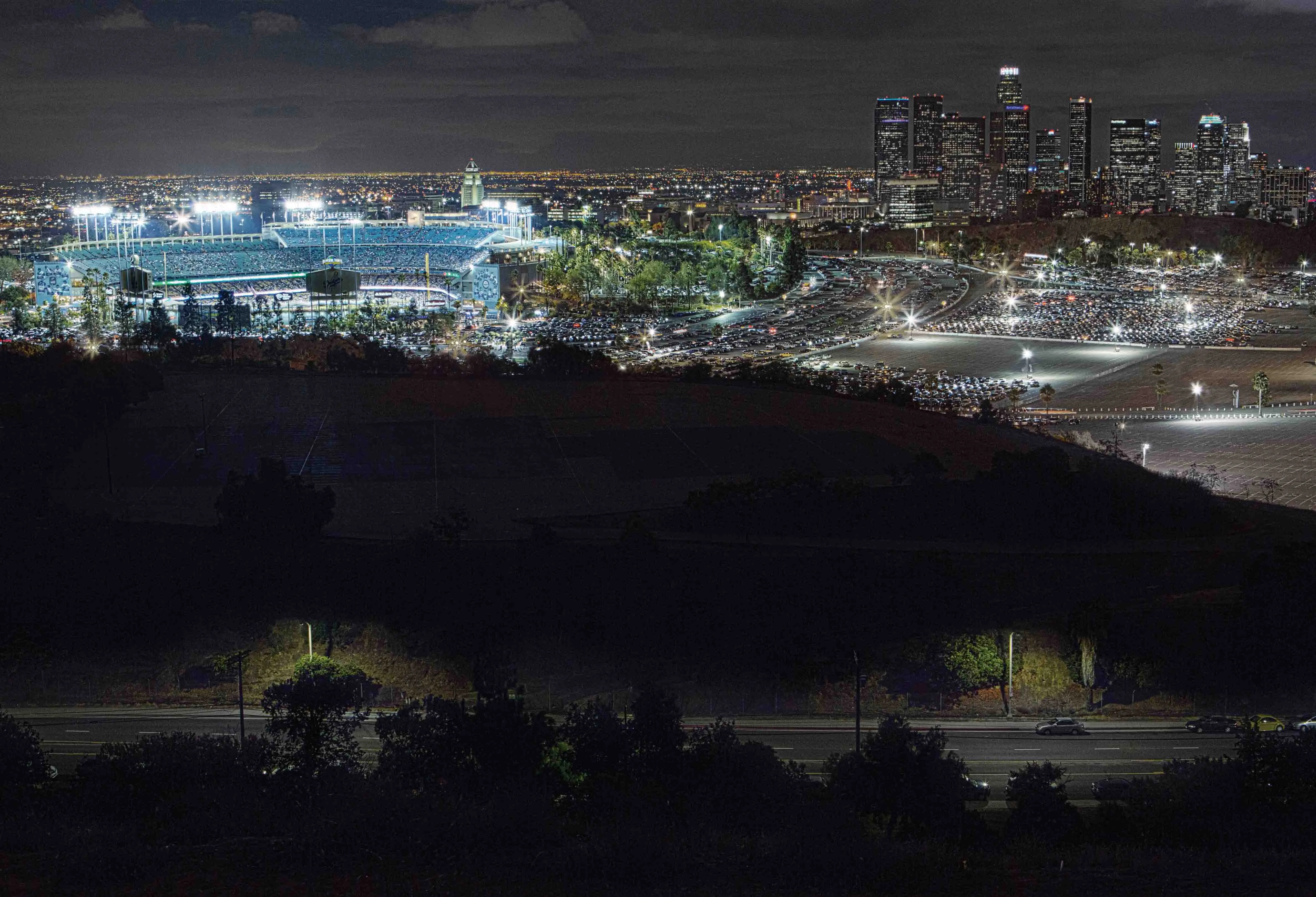

Bertha was made especially for the project by Japanese tunnelling machine specialist Hitachi Zosen. She was shipped in dismantle from Japan to Seattle in spring 2013 then reassembled in a pit nearly 25m deep to the west of Seattle’s athletics stadiums. Bertha’s owner, Seattle Tunnel Partners, the contracting team that’s building the tunnel, is responsible for ensuring she functions properly.

A report by the Seattle Times newspaper, the US$2 billion tunnel is the largest piece of the state’s $3.1 billion programme to replace the Alaskan Way Viaduct. Before tunnel boring started July 30, 2013, state officials said the tunnel would open by the end of 2015. The Times also noted that the front end of Bertha is still dismantled and laying along the downtown waterfront.

But STP said tunnelling will resume on November 23, with the machine emerging at the north end of downtown in late 2016. Traffic will start to use the double-deck four-lane, tolled Highway 99 tunnel from the neighbourhood of Sodo to that of South Lake Union within Seattle in early 2018, according to a revised schedule.

STP has already started some preparation work on the SR 99 southbound roadway inside the first stretch of bored tunnel (see pic).

For the story of Bertha, click on the website of Washington State Department of Transportation.

Bertha, at 17.4m diameter, began her journey in July 2013. She was boring a path to relocate a 3.2km stretch of the elevated State Route 99 Alaskan Way Viaduct, built between 1949 and 1953 and which carries around 100,000 vehicles daily.

The elevated section will be moved underground allowing the creation of public space along Seattle’s downtown waterfront. Options apart from a deep-bore tunnel included replacing it with a cut-and-cover tunnel, replacing it with another elevated highway or demolishing it and not replacing it.

But the construction schedule was severely disrupted in December 2013. After travelling around 305m, Bertha over heated and abruptly stopped. Contractor Seattle Tunnel Partners (STP) discovered damage to the machine’s seal system and contamination within the main bearing.

“Fully disassembling and assessing the machine was always the key to determining how long the repairs would take,” said Chris Dixon, STP project manager. “We want to reassemble the machine and resume tunnelling as quickly as possible, but we also want to ensure the repairs are done right.”

STP and

“The contractor’s schedule has changed, but the contract that governs their work remains the same,” said

“The state is a paying customer in this transaction, and we’re intent on getting what we contracted for. We will continue to protect taxpayers and hold the contractor responsible for their work as they deliver this vital project.”

Bertha was made especially for the project by Japanese tunnelling machine specialist Hitachi Zosen. She was shipped in dismantle from Japan to Seattle in spring 2013 then reassembled in a pit nearly 25m deep to the west of Seattle’s athletics stadiums. Bertha’s owner, Seattle Tunnel Partners, the contracting team that’s building the tunnel, is responsible for ensuring she functions properly.

A report by the Seattle Times newspaper, the US$2 billion tunnel is the largest piece of the state’s $3.1 billion programme to replace the Alaskan Way Viaduct. Before tunnel boring started July 30, 2013, state officials said the tunnel would open by the end of 2015. The Times also noted that the front end of Bertha is still dismantled and laying along the downtown waterfront.

But STP said tunnelling will resume on November 23, with the machine emerging at the north end of downtown in late 2016. Traffic will start to use the double-deck four-lane, tolled Highway 99 tunnel from the neighbourhood of Sodo to that of South Lake Union within Seattle in early 2018, according to a revised schedule.

STP has already started some preparation work on the SR 99 southbound roadway inside the first stretch of bored tunnel (see pic).

For the story of Bertha, click on the website of Washington State Department of Transportation.