Machines from Liebherr have been brought in to carry out a piling job in Colombia in tough conditions. The road network between Mosquera and Balsillas is being upgraded at a cost of some US$199.15 million. Mosquera lies on the outskirts of the capital, Bogotá, while Balsillas is to the south-west and close to the borders with Ecuador and Peru.

Work started on the project to improve the 230km route in January 2016 and is expected to take until December 2021 to complete. One of the contractors involved in the project, Mincivil, is utilising deep foundation equipment from

The ground conditions can be extremely hard, but in spite of this, the LB 36 and LRB 355 rigs are being used to drill 57,000m of piles and are said to be working productively and dependably.

The aim of this construction project is to improve the infrastructure links for freight traffic between Tolima Department and Cundinamarca Department. The work also involves the construction of 16 bridges, which will help to deliver an improved road link between Tolima and Cundinamarca.

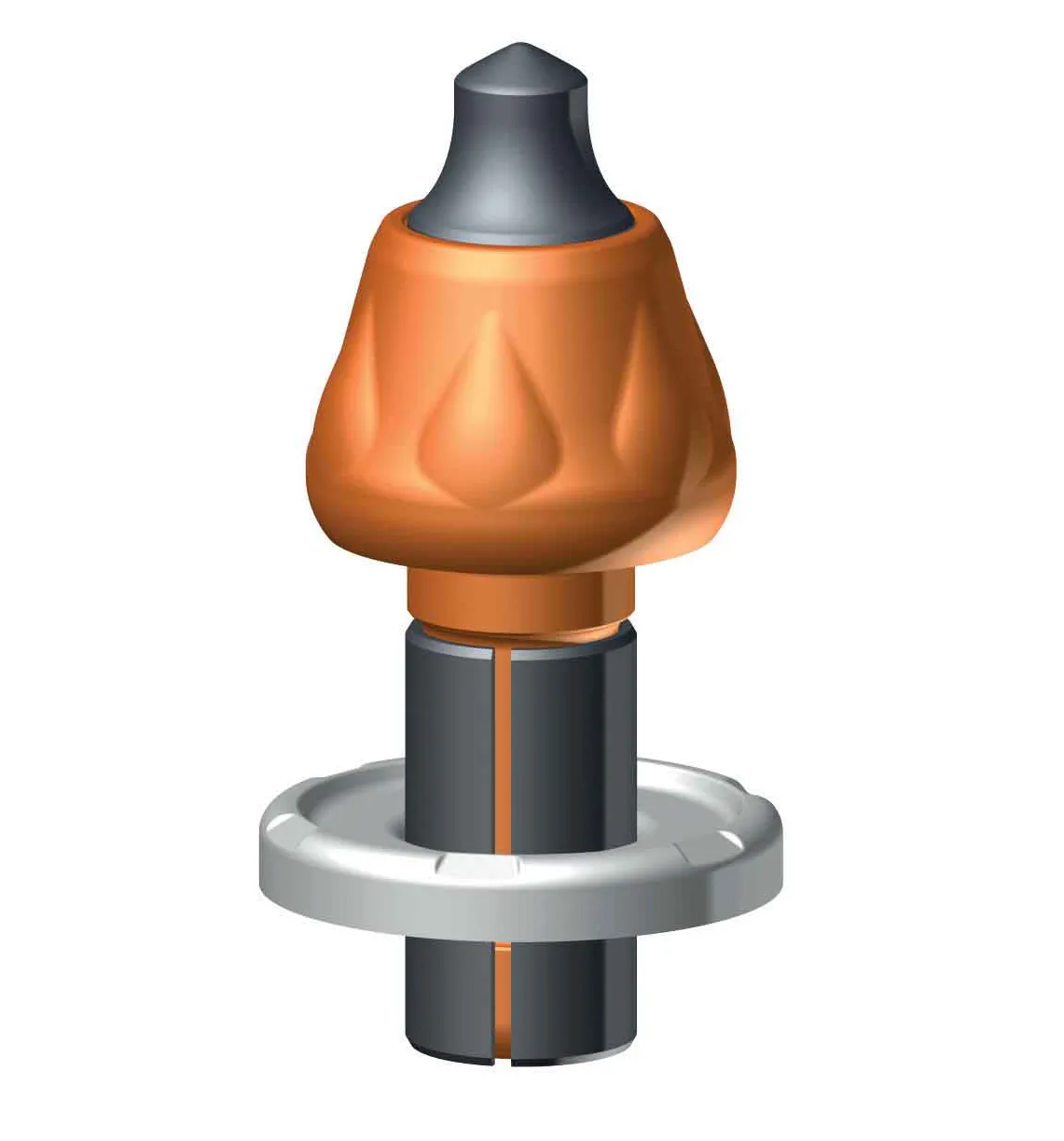

Mincivil is working on the project with another contractor, Topco. To install the piles for the bridges, Mincivil is using the LB 36 and LRB 355 deep foundation machines supplied by Liebherr. The two piling machines are being used for Kelly drilling and full displacement drilling, depending on the specific requirements of each location.

Piles with diameters of 1.5m have been driven to depths of 26m by the LB 36 rig, using the Kelly drilling method. Meanwhile, 600mm diameter piles have been driven to depths of 33m using the LRB 355 piling and drilling rig utilising full displacement drilling equipment. By the end of the piling portion of the contract, the Columbian company will have drilled a total of 57,000m.

The project is substantial and forms part of Colombia’s national road development programme, currently underway. A portion of the upgrade work has already been completed and while the LB 36 finished its work in December 2017, the LRB 355 will be operating until March 2019.

The deep foundation specialist, Mincivil, is located in Cundinamarca, Antioquia and Boyacá. Daniel Rodriguez is Foundation Unit business manager. He said that at a part of the job in Mosquera, nearly an hour by car from Bogotá, the soil conditions have proven hard and challenging due to the nearby mountains. Rodriguez explained, “These are difficult conditions and a real challenge for the machine.”

However, he added that the machines have proven both productive and dependable in the application.