Russian operator company NCC (Nevskaya Concession Company) has placed an order with German manufacturer Herrenknecht for the world's largest tunnel boring machine (TBM). The Mixshield TBM, for construction of the Orlovski Tunnel, "will surpass all previous TBMs" with a diameter of 19.25m and it is designed to construct a mega-tunnel to link both halves of the centre of Russia's second city St Petersburg under the River Neva and speed up traffic.

April 10, 2012

Read time: 2 mins

Russian operator company NCC (Nevskaya Concession Company) has placed an order with German manufacturer Herrenknecht for the world's largest tunnel boring machine (TBM).

The Mixshield TBM, for construction of the Orlovski Tunnel, "will surpass all previous TBMs" with a diameter of 19.25m and it is designed to construct a mega-tunnel to link both halves of the centre of Russia's second city St Petersburg under the River Neva and speed up traffic.At the contract signing, entrepreneur Martin

"Prime Minister Putin wanted to find out at first-hand about the gigantic automobile tunnel project, an extremely challenging construction project under the River Neva," says Herrenknecht.

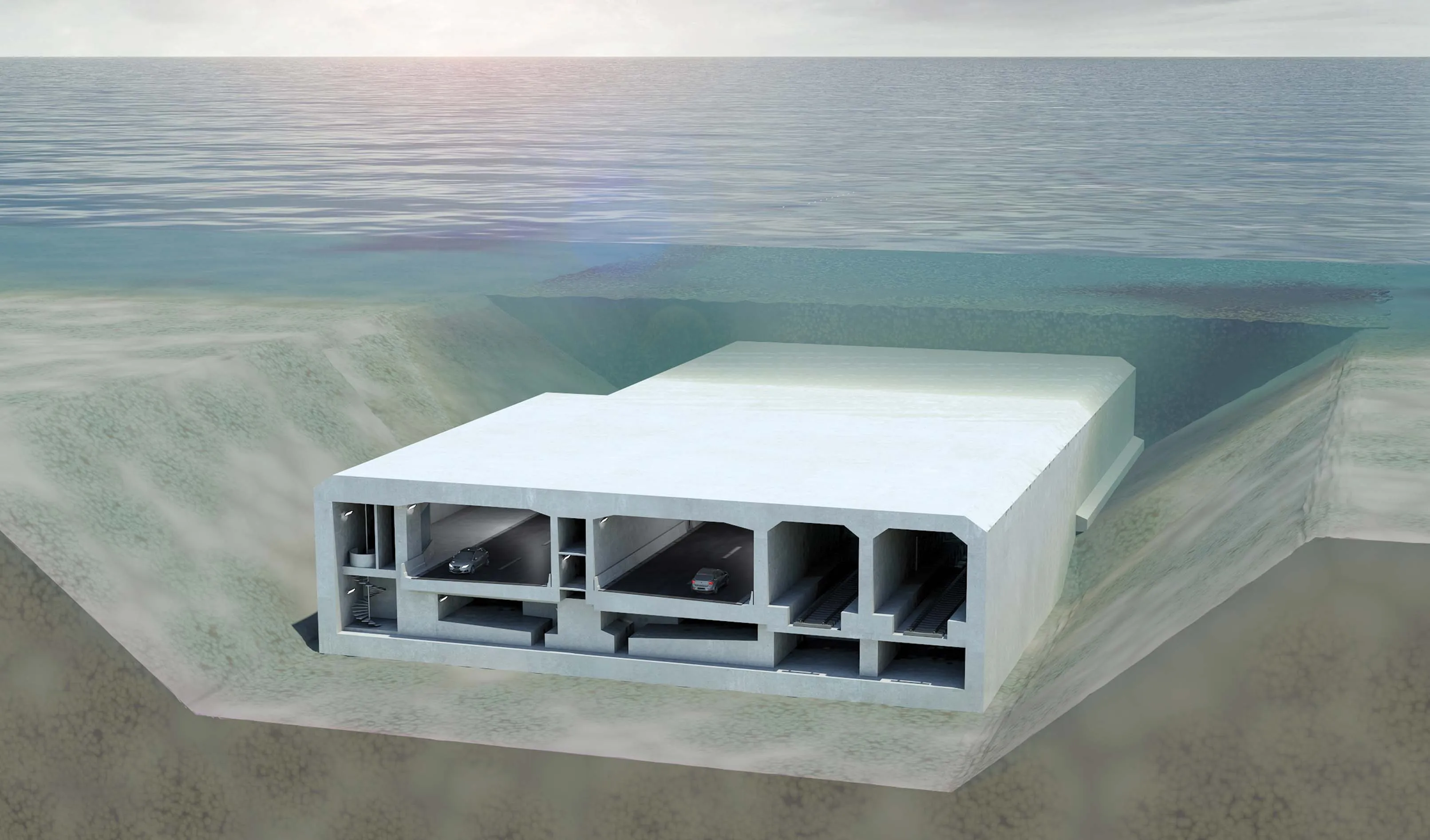

The TBM contract is the biggest single order in the company's history and represents a huge technical challenge, which "has been well prepared by extremely thorough, intensive preparatory engineering collaboration between the customer and the contractor." Including the back-up the Herrenknecht Mixshield will be 82m long, and on its own the tunnelling shield will weigh around 3,800tonnes and deliver 8,400kW drive power to the cutting wheel.

The leap in diameter to 19.25m will enable the machine to excavate 600m³ of soil hourly, and the excavation area is said to be more than 50% larger than that for the largest TBM currently in operation in the world.

"A Mixshield is the quickest and safest solution for driving the around 1km-long tunnel bore under the Neva in the face of the high groundwater pressures. An extremely ambitious timetable has been set for implementation of the project," says Herrenknecht.

Tunnelling is set to begin in St Petersburg in the spring of 2013 with the tunnel due to be taken into operation in 2016.

At present, vehicles have to use the various bridges in order to cross the River Neva from the city centre to the northern districts and the orbital freeway.

The mega-tunnel, with two three-lane carriageway levels will considerably improve the traffic capacity.