A major tunnel construction project has been carried out in Mexico, setting a technological precedent for Latin America

Mexican materials giant

Because the route of the tunnel runs under water the company managing the project, Constructora Túnel de Coatzacoalcos, asked CEMEX to deliver specific concrete solutions for the different structural elements and the agents to which they would be exposed. “Through its quality department, CEMEX worked with us to design the concrete mix used in the tunnel to meet the durability requirements specified by the needs of this project and international standards,” explained Darwin Hernandez, technical manager for the construction project.

CEMEX supplied 48,000m3 of special products, from concrete for the different structural elements to the design and placement of concrete pavement inside the tunnel and the toll area. CEMEX supplied concrete in separate massive pouring of 600m3 and 800m3 for the slabs of the access ramps to the tunnel.

“CEMEX offered its know-how and ability to solve construction challenges. Additionally, it followed up very closely with both the needs prior to the design of the project and the concrete formulations to proceed with the castings,” added Jose Armengol Notario, production superintendent of Producción de Constructora Túnel de Coatzacoalcos.

The chosen construction method was developed in the Netherlands and was selected as it provided the least impact on urban areas. The technique utilised large prefabricated reinforced concrete modules that were produced in a dry dock and then transported to the site for installation under water. For this project, five concrete blocks were built in a dry dock on the banks of the Coatzacoalcos River and later transferred and placed at the bottom of the river.

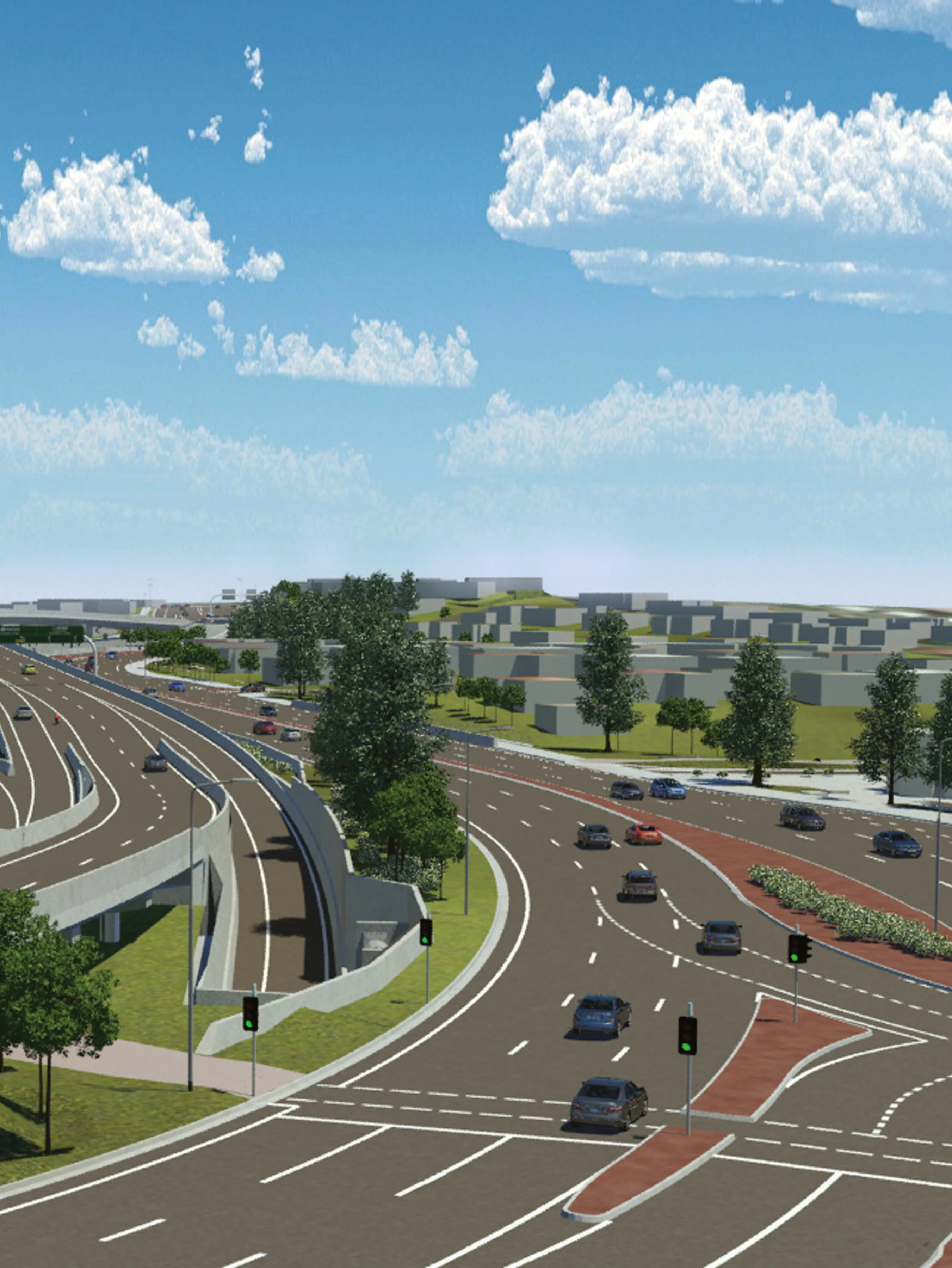

The tunnel features four traffic lanes in all, with two in each direction, and is expected to ease traffic congestion between the Coatzacoalcos urban area and the petrochemical industrial area of Villa Allende. Its effect on congestion is expected to be significant, reducing commuting times from 30 minutes to just three minutes.