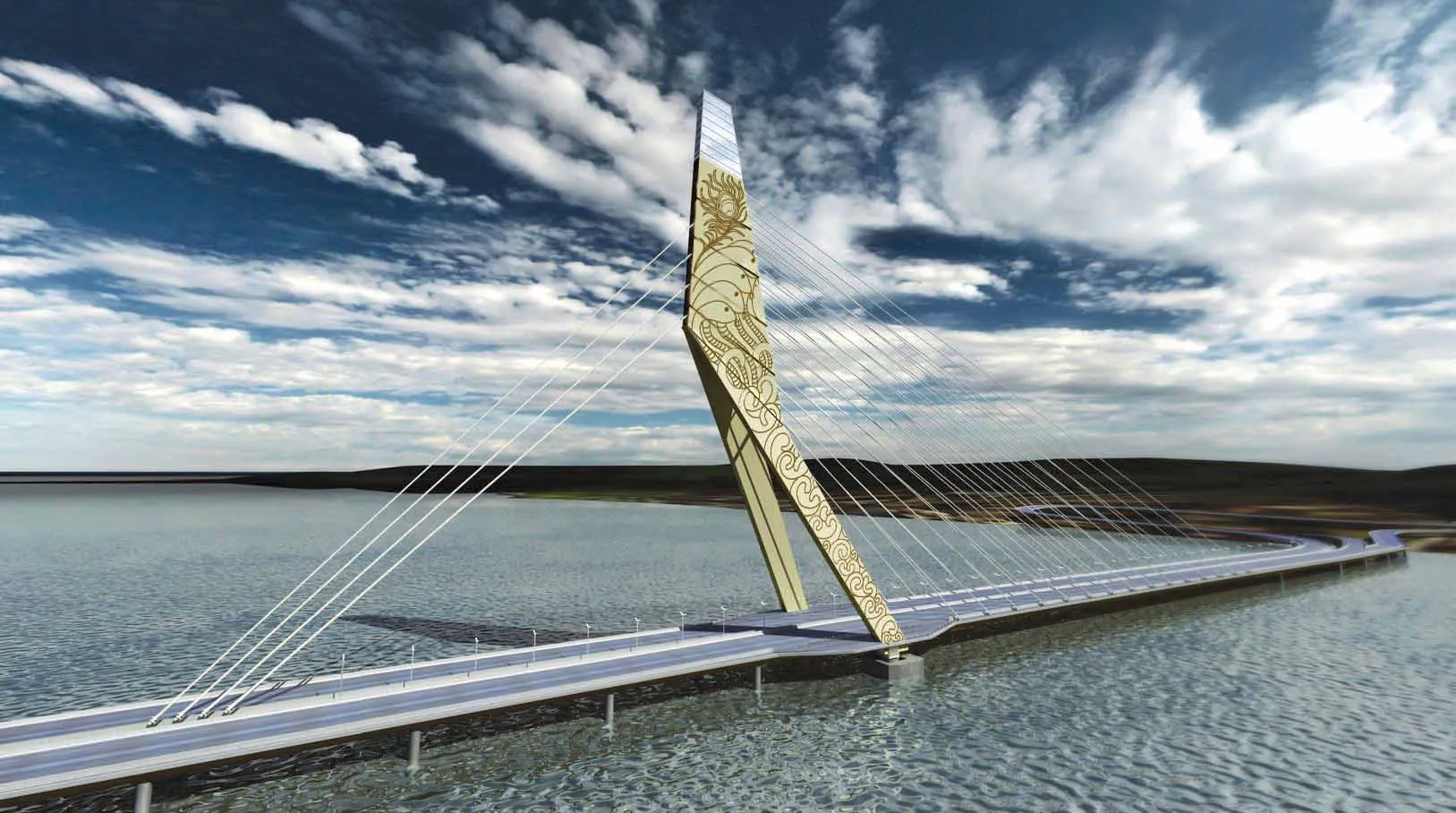

Construction work on the longest bridge in Malaysia and South-East Asia is well underway. Malaysia and South-East Asia is well underway. When completed, the cable-stayed bridge will have a two-lane carriageway and a motorcycle lane in each direction, and will connect Batu Kawan on the mainland to Seberang Perai and Batu Maung on Penang Island. The main span will be 250m long with a length over water of 17km and a 30m height above the water. Costing an estimated US$1.5 billion the 24km long bridge is being b

April 10, 2012

Read time: 3 mins

Construction work on the longest bridge in Malaysia and South-East Asia is well underway. Malaysia and South-East Asia is well underway.

When completed, the cable-stayed bridge will have a two-lane carriageway and a motorcycle lane in each direction, and will connect Batu Kawan on the mainland to Seberang Perai and Batu Maung on Penang Island.The main span will be 250m long with a length over water of 17km and a 30m height above the water.

Costing an estimated US$1.5 billion the 24km long bridge is being built with a large loan from China with construction being carried out by a joint venture comprising the

By the time the signs are ready, the tests and trial runs conducted, it will probably be open to traffic in early 2014. Work on the bridge started in 2008, and to undertake the piling work for the bridge foundations, CHEC bought two of

Piles up to 2m diameter can be driven as standard, and with special attachments larger diameters can be easily accommodated.

Both BSP hammers were fixed on specially built barge-mounted leaders with one working from the shore at Batu Kawan on the mainland while the other worked from Batu Maung on Penang Island.

By April, 2011 piling work was nearly completed but building the pile caps and bridge support piers proved difficult through delays caused when the company had to amend its cap and pier design to ensure they could withstand an earthquake measuring 8.0 on the Richter scale.

Since piling began in March 2009 some 3,000 piles have been driven by each of the two BSP hammers to provide the foundations for the bridge's supporting piers arranged in two parallel rows. The majority are spun concrete piles 1m in diameter and between 57m-60m long with some driven at a rake (batter) of 7:1.

In addition to the concrete piles some 750 tubular steel piles measuring 1.6m in diameter and 77m long were also driven. The piles were driven into the sea bed which consists of soft clay overlaying medium-dense sandy silt. Between five to ten piles were driven per day.

CHEC chose the BSP hammers because of previous experience using the Ipswich, UK-based company's products on other projects, notably a contract to extend the harbour at Tripoli in Lebanon.