Work on the 1.3km Neckar viaduct, part of the A6 motorway at Heilbronn, should be finished by 2022. It is part of the A6 expansion project between the Weinberger junction and Wiesloch/Rauenberg.

The project is officially the new Neckar viaduct BAB 6 at Heilbronn. Federal Motorway 6, the A6, is also known as the BAB 6. The 477km motorway starts at the French border near Saarbrücken and ends at the Czech border near Waidhaus. It then continues through the Czech republic to the capital Prague. Internationally it is known as Via Carolina.

Around US$21 million was spent on renovating the structure only in 2003 but it has been struggling to handle 100,000 vehicles a day. The extension of the 25km section of motorway for an estimated €1.3 billion was announced at the start of 2017. It was immediately clear that the greatest challenge would be construction of the new six-lane bridge over the Neckar River.

ViA6West, the public-private partnership is working with partners

ViA6West is now constructing the temporary bridge next to the old 1960s bridge in two steps. The first is building a foreland bridge with launching girder and the second is constructing the section over the Neckar using the incremental launching method.

The two sections will meet and be connected shortly before Neckar island. The entire superstructure with the travel lanes and the noise barriers is already complete. Subsequently, the old bridge will be demolished and the final foundations and piers erected.

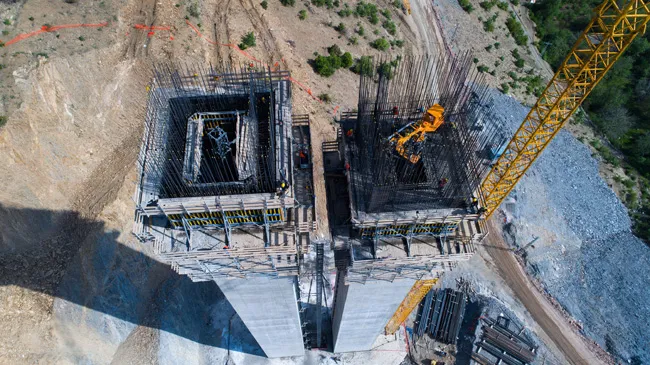

“Building a bridge of this size parallel to the old bridge and then moving it laterally into position is literally a mammoth task,” said Andreas Scherzl, a Munich-based project supervisor. “Foundations for the abutments and the bridge piers are being poured using Meva’s Mammut 350 formwork system, as are the bridge piers themselves.

“The KLK 230 climbing platform and the Space shoring tower ensure that formwork can be erected safely. The launching beams on the piers of the temporary bridge also play a key role to ensure that the entire construction can be manoeuvred laterally into its final position after completion of the superstructure complete with travel lanes and noise barriers,” explained Scherzl.

Meva’s special design department was required for work on round pier columns and the pier heads in the area of the steel reinforced concrete bridge directly above the Neckar River. Alexander Schmid, who is supervising the work, said a 3D programme was used to get the precise bending and twisting in the four formwork panels. At the customer's request the formwork panel had to have a wooden surface.