Rainfall patterns and type of soil in an agricultural rich area shared by the neighbouring East African countries of Kenya and Uganda was a key consideration in arriving at the decision to upgrade to bitumen standards 73km of the 118km Kapchorwa-Kitale road that links the two countries. Initially, Uganda had proposed to have the road between Kapchorwa and Suam on its border with Kenya re-gravelled and widened to address transport problems in the area that runs north of Mount Elgon National Park through Kapchorwa, Kween and Bukwa districts.

“Despite the periodic maintenance operations by Uganda National Road Agency (UNRA), the existing gravel road seriously deteriorates and becomes impassable whenever it rains due to black soils,” said Uganda’s State minister for planning David Bahati. The Ugandan Government sought parliament’s approval of a US$105.7 million loan from the

AfDB last year approved $147.3 million and $103.7 million for Kenya and Uganda respectively which is equivalent to 89% and 88% of project financing for the countries. Kenya and Uganda are providing 11% and 12% of the project financing respectively.

Earlier, a brief on the project said widening and re-gravelling of the Kapchorwa-Suam stretch was not economically sustainable in terms of costs and the lifespan of the road. It also said the link “cannot effectively handle the predicted 15% annual traffic volume growth for the region with high economic potential.”

“Heavy rains ranging from 800mm to 1200mm which characterises the region will necessitate road re-gravelling every two years to maintain it in modest motorable condition,” the brief says.

“Re-gravelling will demand a frequent maintenance regime and high volumes of murram (gravel) which is not only scarce in the project area, but also whose acquisition poses the risk of environmental deterioration and landscape/visual blight,” it adds.

Uganda has opted for a Class II paved road that entails upgrading the gravel road to asphalt concrete surface with a base course and sub-base layers.

In addition, the preferred contractor for the Kapchorwa-Suam section, who is yet to be announced, will rely on a road design with improved geometric design of the existing alignment, drainage and safety conditions according to UNRA.

UNRA says the two-lane road will be 3.5m wide with boulder width of 1.5m and a parking lane and footpath on either side of 2.5m and 1.5m wide respectively.

If completed according to schedule and design, the road’s first maintenance will be in 2033. The road upgrading includes improved back benched and grassed embankment to mitigate the effects of possible slope failure and any likely landslides.

On the Kenyan side, 18km of the 45km earmarked for upgrading is currently of bitumen standard but in very poor condition, while the other 27km stretch is a flat and rolling gravel alignment crossing rivers Kaibei, Mubere and Suam that require an asphalt concrete surface for the first time.

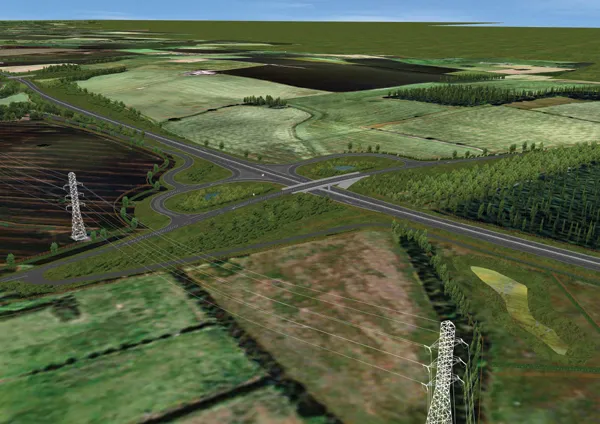

At Eldoret, the contractor will construction a 32km road bypass to divert traffic from the town’s A104 stretch, which is part of the Northern Corridor that links the port of Mombasa to Uganda, Rwanda, Burundi, South Sudan and eastern Democratic Republic of Congo. The bypass is a 7m-wide single carriageway with 2m-wide shoulders on either side. Three junctions, an overpass and a rail bridge are key features of the Eldoret bypass.

A trumpet junction will be built over A104 at Cheplaskei while a half clover one with a loop over C39 will be constructed at Kapsaret.

The contractor will also build an overpass running over the new bypass at Simat, a road-rail bridge on the existing railway line and a full clover junction with loops over A104 at Leseru.

At both Kapsaret and Leseru, the contractor will construct two truck parking lots close the interchanges.

The entire Kapchorwa-Kitale road project, although being implemented separately by Kenya and Uganda, is expected to be completed in 2021, reducing travel time by 50%.

According to the project brief the design of the upgraded road “will minimise accident risks by speed calming measures and appropriate and clear road signage.”

Part of the project includes refurbishment of dilapidated post-crash care centre and procurement of an ambulance and theatre equipment to boost the road safety emergency response whenever there is a road crash.

The Kapchorwa-Kitale project is considered vital in the integration of the East African economies under the East African Community.