It was “dirty work” for drainage engineers from Lanes Group in the UK when they recently removed 400tonnes of silt and debris from a culvert in northern England.

Before sludge removal started, the 3m-wide concrete box culvert under the A38 on the outskirts of the city of Derby had been full almost to its roof.

Lanes Group's East Midlands depot, based in Derby, desilted the culvert in a 17-day operation for North Midland Construction, working for Highways England, under its civil engineering framework.

March 28, 2017

Read time: 3 mins

It was “dirty work” for drainage engineers from Lanes Group in the UK when they recently removed 400tonnes of silt and debris from a culvert in northern England.

Before sludge removal started, the 3m-wide concrete box culvert under the A38 on the outskirts of the city of Derby had been full almost to its roof.

7891 Lanes Group's East Midlands depot, based in Derby, desilted the culvert in a 17-day operation for North Midland Construction, working for 8100 Highways England, under its civil engineering framework. Prevention of localised flooding is a key component of Highway England'sfi ve-year road maintenance programmes up to 2021.

Highways England commissioned the culvert clearance work to optimise flood resilience along the stretch of A38 next to Derby's 84-hectare Markeaton Park, the most popular municipal recreation area in the Derby vicinity.

The 60m-long culvert was built in 1977 to route a water course called Bramble Brook, which leads from a large lake in Markeaton Park, under the nearby A38 dual carriageway.

North Midland Construction Project Manager Paul Devine acknowledged that is was “hard and dirty” work. “Much of it had to be done by hand but their ‘confined space working’ health and safety measures were spot on.”

Samples of the in situ silt were first scientifically tested to assess potential toxicity. North Midland Construction built two temporary dams at the upstream and downstream ends of the culvert to retain the water flow during the works. Excess water was managed using 150mm water pumps.

A substantial amount of mobilisation work was also carried out to prepare the working area. This included site security, tree trimming and construction of a 100m temporary road to the culvert to allow safe access for Lanes vehicles and protect utility assets under soft ground. A scaffold platform was also built to gain safe access to the mouth of the culvert.

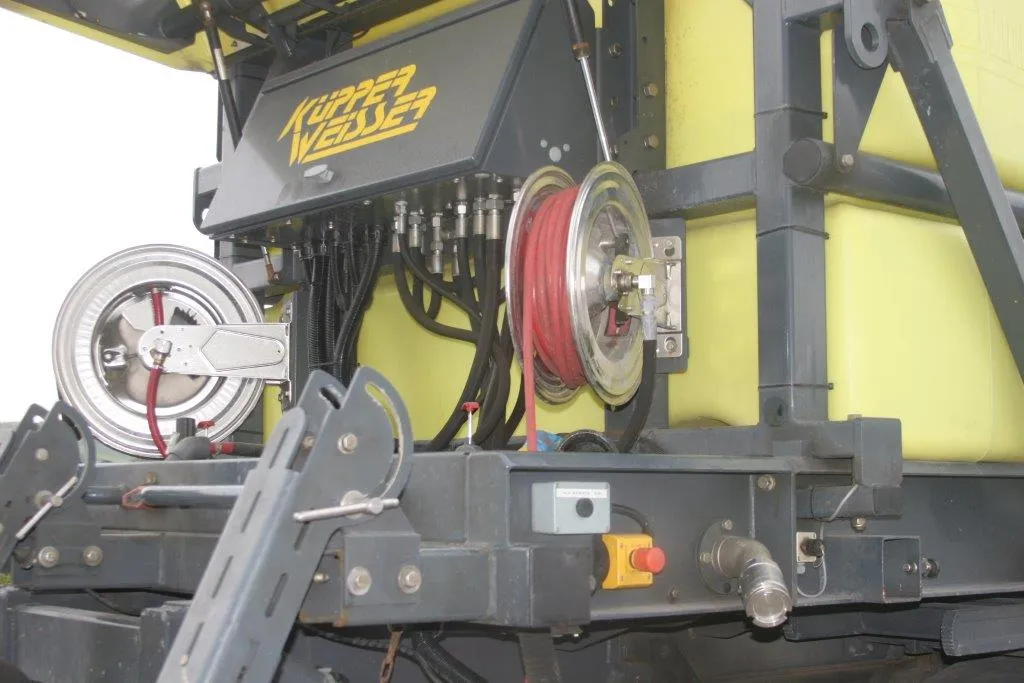

Lanes then deployed seven drainage engineers and excavation operatives at any one time on the project, along with a powerful Superflex wet-dry vacuumation tanker and a jetvac tanker. Up to four Lanes employees worked in the culvert shovelling and raking silt into the Superflex's vacuumation hose.

Next, the material was over-pumped to the jet-vac tanker and taken away for disposal at an authorised waste site. Members of the confined space working team wore wet suits, rescue kits, gas monitors and harnesses, allowing them to work continuously. Throughout the operation, a specialist two-person rescue team monitored conditions inside the tunnel and also weather conditions. A supervisor managed a tag board recording details of all operatives below ground.

Before sludge removal started, the 3m-wide concrete box culvert under the A38 on the outskirts of the city of Derby had been full almost to its roof.

Highways England commissioned the culvert clearance work to optimise flood resilience along the stretch of A38 next to Derby's 84-hectare Markeaton Park, the most popular municipal recreation area in the Derby vicinity.

The 60m-long culvert was built in 1977 to route a water course called Bramble Brook, which leads from a large lake in Markeaton Park, under the nearby A38 dual carriageway.

North Midland Construction Project Manager Paul Devine acknowledged that is was “hard and dirty” work. “Much of it had to be done by hand but their ‘confined space working’ health and safety measures were spot on.”

Samples of the in situ silt were first scientifically tested to assess potential toxicity. North Midland Construction built two temporary dams at the upstream and downstream ends of the culvert to retain the water flow during the works. Excess water was managed using 150mm water pumps.

A substantial amount of mobilisation work was also carried out to prepare the working area. This included site security, tree trimming and construction of a 100m temporary road to the culvert to allow safe access for Lanes vehicles and protect utility assets under soft ground. A scaffold platform was also built to gain safe access to the mouth of the culvert.

Lanes then deployed seven drainage engineers and excavation operatives at any one time on the project, along with a powerful Superflex wet-dry vacuumation tanker and a jetvac tanker. Up to four Lanes employees worked in the culvert shovelling and raking silt into the Superflex's vacuumation hose.

Next, the material was over-pumped to the jet-vac tanker and taken away for disposal at an authorised waste site. Members of the confined space working team wore wet suits, rescue kits, gas monitors and harnesses, allowing them to work continuously. Throughout the operation, a specialist two-person rescue team monitored conditions inside the tunnel and also weather conditions. A supervisor managed a tag board recording details of all operatives below ground.