It was announced in September 2016 that Belgian group

The project is officially called the Fjord Link Frederikssund Design & Build Contract. It consists of a four-lane 8.2km dual carriageway – part of Denmark’s Primary Route 53 – with a “High Bridge” over the Roskilde Fjord. Shipping clearance will be 22.2m. The road links the town of Frederikssund on one bank with the Hornsherred Peninsula on the other bank.

“The in-house engineering department of BESIX makes the difference in design and build projects such as this one,” said Jean Polet, BESIX’s general manager for Europe, at the time of the contract award in 2016. “It offers integrated expertise which enables us to coordinate the design and the execution in the best way possible, guaranteeing a surplus of added value for the client.

“The project is special because it solidifies our first steps on Scandinavian soil. This makes us and our partners extremely motivated,” noted Polet.

The design phase of the project started in November 2016 with on-site work beginning in February 2017. By late 2019, the final asphalt layers will be completed and the bridge will be open.

The project includes a 1.4km tolled bridge over Roskilde Fjord and 11 smaller civil structures including bridges, fauna passages and cycle lane passages along the highway sections. The new road and bridge is expected to relieve traffic on the nearby 1935 bascule bridge Kronprins Frederiks Bro located further down the fjord, closer to the open sea.

Congestion on both sides of Roskilde Fjord has become a problem, in particular around Frederikssund. The town on the east coast of the shallow Roskilde Fjord with a population of 16,000 lies about 45km north-west of Copenhagen. It’s closeness to the Danish capital means it is becoming more popular as a commuter town.

The old 30m-wide Kronprins Frederiks Bro has a middle span of 29m. Like many of Denmark's older bridges built before the Second World War, it will be expensive to keep going, says Henrik Vincentsen, the Danish Road Directorate’s project manager. However, their value today is just as great to the transportation network because they connect smaller islands to each other (see box). “A lot of people’s shortest route is on an older bridge and if you remove it you create more traffic for the new bridge which is really for through-traffic.

“The new bridge is a an expressway, like a motorway but with no emergency lane, so bicycles, pedestrians and – importantly – slow-moving farm vehicles are not allowed,” says Vincentsen.

Improving transportation infrastructure in Denmark’s pastoral areas is a delicate task, both politically and environmentally. The fertile land of the Roskilde Fjord area is extensively farmed with an emphasis on cereals, root crops and pigs. On top of this, the Frederikssund region is a designated Natura 2000 area as it is a habitat for sensitive vegetation – eelgrass, in particular - and an important refuge for migrating water fowl. Natura 2000 is the European Union’s network of core breeding and resting sites for rare and threatened species across all 28 EU member countries, both on land and at sea. The aim of the network is to ensure the long-term survival of Europe's most valuable and threatened species and habitats.

However, Natura 2000 is not a system of strict nature reserves from which all human activities would be excluded. While it does include some strictly protected nature reserves, most of the land remains privately owned. Infrastructure development can be allowed but under strict rules and regulations of member countries to ensure the survival of the area’s wildlife and fauna.

For the Roskilde Fjord project, one of the issues is the flowering underwater plant Zostera Marina, commonly called eelgrass. It grows to less than 1m long in shallow water with a depth of around 3m. Eelgrass beds are always completely submerged and their roots, known as rhizomes, anchor the grass to sandy or muddy bottoms. By trapping sediment, stabilising the substrate and reducing wave energy, eelgrass beds reduce coastal erosion – important for the fjord. For this reason, BESIX and its joint-venture partners have had to be extra careful when drilling bridge piles into the fjord bed.

According to the Danish office of UK-based engineering consultant Arup, the design of the bridge structure focused on eliminating columns to reduce the impact on the bed of the fjord. A drilling method for the underwater piles using protective permanent casings was adopted to reduce the impact on the environment.

It ensured that construction works which stir up sediment are not performed during the growth period for eelgrass. Sediment screens were used to prevent sediment from dispersing. The plant, therefore, receives sufficient light during the critical moment in its life cycle.

Also, construction that generates the most noise has been scheduled for when migratory birds are not present in the fjord.

Location of residential areas very near to the construction site and no road access to the Fjord’s banks has added to challenges for contractors over logistics, dust, noise and traffic management. For example, the highway section passing through the quiet holiday village of Tørslev Hage is placed in a cut between sheet piling walls to protect nearby residents from noise and dust.

Shallow water

“There is no real depth in the fjord, only 3-4m in the navigation channel, and maybe 11m at the deepest in the fjord,” says Steen Pedersen, the joint venture’s coordination and stakeholder manager. “The coastal area is very shallow and you can walk out 400m and be only waist-deep in water from the western side,” says Steen who has seen environmental issues creep steadily up the priority list for clients and contractors.

“I started in 1969 on the Weaver Viaduct near Chester [UK] where we crossed a river and bird sanctuary that we had to take into account. But I then moved to work in Brazil in 1973 where, as you can imagine, the environment was not really an issue at that time.”

How times – and priorities – change. “We were not allowed to dredge a lot in the Roskilde Fjord, so we couldn’t barge in a lot of heavy equipment and material to the site. That is one of the reasons why we launched from the shore on temporary embankments built out into the fjord.”

The two embankments are made of simple sheet piles with gravel infill, all of which will be removed and the shoreline restored.

Piers, or pile caps, usually jut out of the water and are protected by heavy stone reinforcing against ship collision damage and ice damage. But because the Roskilde Fjord is so shallow, the only ships are small leisure craft. Also, the weather from December to March is not extreme, despite being in Northern Europe. It may hit 0oC but rarely dips to -10oC, meaning there is little ice for which the bridge must contend. For the Roskilde Bridge, the pile cap - upon which the v-shaped pylonsrest - is cast so that the top is about 3.5m below the water surface. This is just low enough that small leisure boats won’t hit it head-on if they pass close to the bridge.

To protect residents against noise, there was silent piling – hydraulic jack piling - as determined by the contract. “There is a problem if you encounter boulders but the contract allowed for traditional piling to overcome the obstacle. But once passed through, silent piling had to recommence,” says Pedersen.

Limestone fault

In August, the substructure of the bridge was completed. It includes 16 piers, in addition to the two abutments – one on each bank – and onshore and offshore piles. Three of the 16 piers are anchored on shallow foundations, while the rest are on bored piles - four piles per pier. The offshore work required construction of a temporary harbour for the maritime resources, while onshore pile work was completed using the temporary embankments on each side of the fjord.

In centre of the fjord there is a fault and the limestone is deep there, around 40m below the seabed, whereas closer to shore it is only 25m or so below the seabed. The design allows for bored piles into the limestone, explains Vincentsen. The deepest piles are around 2m wide and 48m long of which around 6-8m is buried into the limestone.

“From preliminary investigation we knew the bridge would be pile-founded so our illustrative design had span widths of 73m and 18 piers [pile caps] that are supported by the piles,” says Vincentsen. “We tendered with a contract with a competitive dialogue structure allowing the winner to optimise the basic design.”

Still open for business

Daily traffic across the Crown Prince Frederiks Bridge (Kronprins Frederiks Bro) was 16,000 vehicles in 1995. Now, around 21,700 – a 30% jump – use the 83-year-old bascule bridge each day. At weekends, there is little respite, thanks to the many cottage owners heading to the Hornsherred Peninsula.

The bridge is raised for limited times only and outside rush hour which reduces vehicle congestion and tail-backs as much as possible. Meanwhile, the new crossing – called Kronprinsesse Marys Bro - is expected to handle upwards of 13,000 vehicles a day. This will hopefully relieve much of the congestion on the old bridge which will remain in service for local traffic including farm vehicles, pedestrians and cyclists.The winning design from the joint venture RBAI came up with an 83m span which reduced the number of piers by two, meaning fewer piles as well. “It’s a trade-off because you might have to put more construction into the superstructure but save on the foundations,” he says.

The result is 15 spans and two two-third spans – two fewer spans than the preliminary design. The span between the abutment and first pier on each side is a two-third length span. Each span has 30 prefabricated deck segments placed by a travelling launching gantry from specialist contractor Rizzani de Eccher.

Rizzani’s number 112 gantry unit came immediately from a bridge project in Canada and it is only the second time that such a system has been used in Denmark, says Vincentsen. Rizzani has a lot of experience, including in the Middle East, and the competitive dialogue approach to the contract allowed Vejdirektoratet to tap into this knowledge.

“If a project is straightforward, there is no need for competitive dialogue,” he says. “The challenge was that this is the largest bridge to be built since the Oresund Bridge which opened in 2000, nearly 20 years ago. We realised we didn’t have the internal departmental experience to design such a structure. If you look at the four bids we got, there were three construction methodologies. And still, the three top contenders were very close on price. So it wasn’t obvious what would be the right solution and we had to keep our options open,” says Vincentsen.

Pier construction

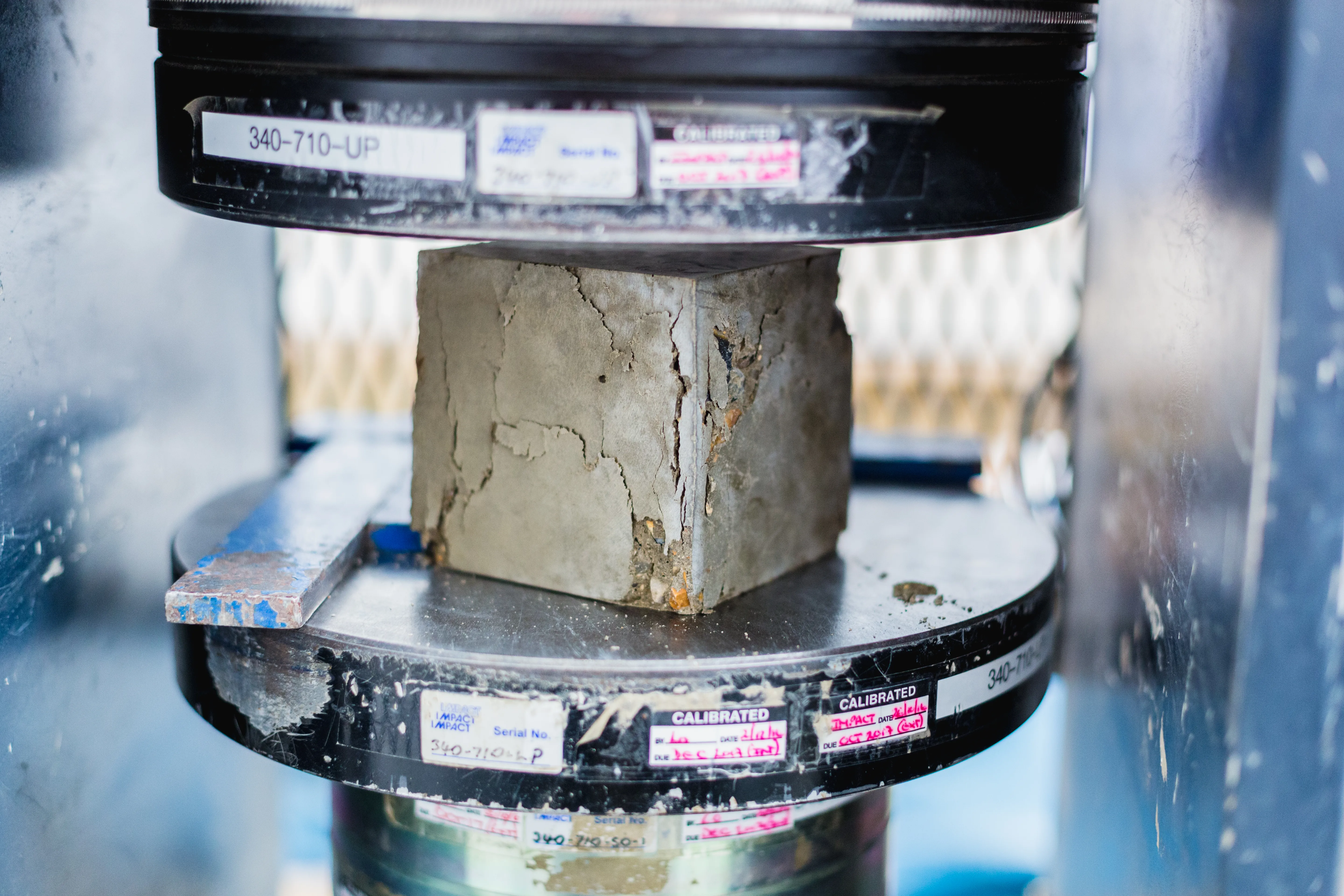

Each pier is attached to four piles. To create a pile cap for the superstructure’s supporting V-shaped pylons, a drilling rig places a cylindrical steel pile casing down onto the Fjord bed and the pile hole is bored into the bed. Steel reinforcement is inserted into the casing and concrete is poured into the assembly to create the pile.

To form the poured concrete pile cap, a prefabricated concrete caisson with cut-outs for the four piles were lowered down over the piles. The technical challenge is that, despite its mass of around 130tonnes, the concrete caisson floats, says Xavier Debruche, design and technical manager with BESIX. An additional steel caisson is placed on top of the concrete caisson to force it downwards into the water. It also acts as a coffer dam into which workers can create the pier cap.

To also counter the concrete caisson’s floatation, beforehand a steel ring is placed around each pile someway down in the water. Divers secure the rings to the piles with large bolts. Around 20cm of high-resistance grouting is laid around the top of the ring, where the concrete caisson will rest once it is lowered down into the water and bolted onto the piles.

Joint venture RBAI: who’s who

BESIX - Belgium; marine technology and underwater construction

Rizzani de Eccher – Italy; deck construction including prefabrication

Acciona Infraestructuras – Spain; main local subcontractor - MJ Erikson; roadworks and minor structures

DESIGNERS FOR RBAI ARE:

For High Bridge: SHP (Stráský, Hustý a partneři, s.r.o.)

Remaining project: SWECO, Denmark

ARUP is assisting the client (Danish Road Directorate) with bridge design workOnce secured to the piles, water is pumped out of the concrete caisson and steel caisson combination. More grouting is placed around the contact area of the concrete caisson and pile. Additional steel plating is welded around the pile-caisson area to make it watertight.

Next, the concrete caisson is filled with poured concrete to form the pier or pile cap. Once cured, work can begin inside the steel caisson on the bridge V-shaped pylon whose base is below water.

When construction of the pylon is well above water level, the steel caisson is cut away and removed for disposal on land.

Another technical challenge, explains Debruche, was curing the grout sufficiently to get the required strength. “Water temperature was around 1oC but the grout needed to achieve strength very fast. So we used electrical cables inserted into the grout to heat it and speed up the curing.”

When electrical resistance reached a certain point, the grout had cured sufficiently, he says. “Heating the grout means it is ready in around five days. If you didn’t heat it, it could be a month depending on the temperature on the water.”

For much of the pier concrete work, extensive systematic concrete temperature modelling was adopted. “The temperature should be 70oC and the maximum delta temperature of the concrete – surface and core - around 30oC maximum. For any concrete larger than 50cm in width, we made a model to simulate the temperatures and external condition of the concrete through the day and night.”

In practice, to ensure proper curing of concrete, wireless temperature sensors were placed in the casting area which then became embedded in the poured concrete. “While this has become more common, this project is the first time in my 20 years that I have seen it used so exhaustively and systematically on any civilian and marine project,” says Debruche

As the year-end fast approaches, so does the end of deck segment placement. The target is to finish the bridge and have it open ahead of the October 2019 deadline. Finishing works include mechanical and electrical equipment installation, drainage systems, waterproofing, the laying of asphalt and barrier erections.

Made in Poland

The deck consists of 492 segments, all made in Poland by a concrete fabricator within BESIX’s established supply chain. They could have been made on site but the expense in money, as well as time, was going to be prohibitive, says Steen.

Although rural, the area is heavily populated so noise from onsite manufacturing and truck traffic bringing in raw material was going to be an issue. Also, the Danish construction market has been very buoyant for some years which makes it difficult to get people with the right manufacturing skills, not to mention getting enough raw material.

“Concrete suppliers in the area are already very busy, so we would have had to make ready-mix concrete on site as well. You need many government approvals for setting up onsite manufacturing, so there are a lot of risks.”

Transporting in the segments meant only one transportation route needed to be authorised. The sole depot for storing the segments beside the bridge will be returned to farming when the project is completed.