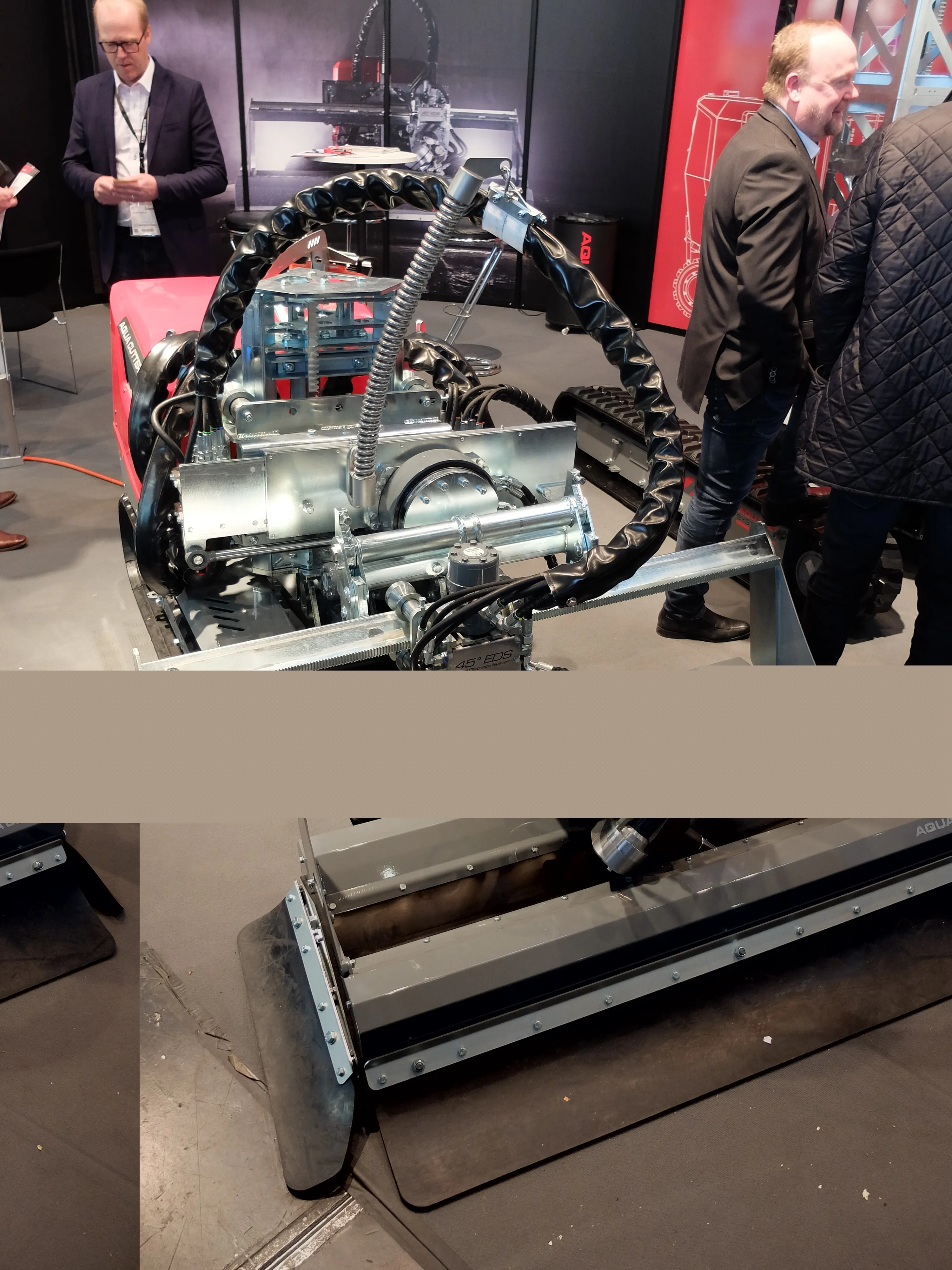

The firm’s latest Rotolance 2500 was used alongside an Aquacutter 710 VE evolution on the Viaduc de Chillon link, above Lake Geneva. The machines were used by Zurich-based hydrodemolition specialist contractor, Walo Hydrodynamik, to remove more than 25,000m³ of concrete deck on the bridge.

The Viaduct was completed in 1969 and comprises two structures 12m wide, carrying the east and west bound lanes of the Swiss A9 autoroute. Both viaducts span a total of 2.15km at a height of 100m above the lake and are staggered several metres in height.

The viaduct carries heavy traffic volumes, up to 50,000 vehicles/year, and was in need of repairs. Investigations in 2013 found that the concrete decks were affected by alkali aggregate reaction (AAR), with the alpine aggregates used being badly affected.

Walo was awarded the contract to remove 3 – 5mm depth of the concrete deck on the east bound lanes in Phase 1. The deck then benefits from a new reinforced, ultra high performance special concrete developed by

Earlier in 2014, Walo also took delivery of the latest Rotolance 2500 in Switzerland ready for the Viaduct project Phase 1, together with a 4m long mast extension.

“The unit is operating on-site at 2000 bar and 120 litre/minute to achieve rates of 100m²/hour,” said Zuberbhler.

With the Rotolance traversing along the 4m long extension beam, it has been programmed to automatically advance 160mm/cycle as the unit reaches the end of the beam. In addition to removing the pavement to a depth of 3mm, it has been used to make five 2mm deep channels across the deck to consolidate the new concrete to form a stronger bond over the four subsequent concrete pours. Two of these are 200mm wide and three are 250mm wide.

Work on Phase 2, also awarded to Walo for the west bound viaduct, will begin in 2015 in a repeat operation to remove 25,000m³.

On completion of Phase 1 the Aqua Cutter and Rotolance combination will be transferred to its next ‘job’ on the E8 highway at Interlaken to remove 5,000m² of concrete pavement to a depth of 5mm and a further 5,000m² on the tunnel walls to a depth of 3mm.

“The Rotolance 2500 is the perfect tool for deck removal where the depth is between 0 – 5 mm and over very large areas,” said Zuberbhler.

Atmat is one of Aquajet Systems oldest dealers and has been responsible for promoting hydrodemolition technology across Switzerland where there is a need to repair and widen many ageing concrete structures. According to Alessandro Campa, director of Atmat, the technique is set to grow even further in Switzerland as the country tries to keep its infrastructure abreast of the ever-increasing population. He said, “Highways, for example, were built with 2 lanes for a 40 years life span but this has been overtaken by the population growth. Today we must start to increase them all to three lanes.”