AN INNOVATIVE slurry wall solution has been used by Bachy Soletanche at the Alderley Edge By-Pass project in the UK. Bachy Soletanche provided assistance for the A34 Alderley Edge by-pass project in the UK being carried out by main contractor Birse Civils. This solution was required to tackle challenges posed by the water table at the Welsh Row section. Bachy Soletanche used its experience with slurry cut-off walls, a technique rarely used in Britain on road construction, to benefit a tricky section of the

April 4, 2012

Read time: 4 mins

AN INNOVATIVE slurry wall solution has been used by 1485 Bachy Soletanche at the Alderley Edge By-Pass project in the UK. Bachy Soletanche provided assistance for the A34 Alderley Edge by-pass project in the UK being carried out by main contractor Birse Civils. This solution was required to tackle challenges posed by the water table at the Welsh Row section.

Bachy Soletanche used its experience with slurry cut-off walls, a technique rarely used in Britain on road construction, to benefit a tricky section of the project.

The A34 bypass around Alderley Edge in Cheshire is a major UK road project. The link crossed existing infrastructure, in particular the main Manchester to London railway link.

Due to environmental reasons the bypass has to run under the railway line with the road level in a cutting and the road box formation 6m below the ground level at the Welsh Row section.

The location posed several challenges for1486 Birse Civils, as the ground to the north and south of the railway has a very shallow water table, ranging from 1-3m below ground level. In this particular area and in a wet period, the water table can rise to just below the surface.

The major issue is that cutting through this area would draw down the high water table, which could have an affect on the structural integrity of the railway track. And should the water table have been altered in any way it could have affected the surrounding area by way of drying out wet areas.

One of the biggest challenges facing the designer was to overcome the problem and create a barrier, preventing water seepage to maintain the natural water table levels. Several options were examined including sheet piling or piled wall techniques, but the most cost effective solution to this problem was to create a slurry cut-off wall. A slurry wall is a non-structural barrier that is constructed underground to impede groundwater flow and is often used on land reclamation projects.

Bachy Soletanche, along with Birse Civils, Cheshire East Council and geologists planned the details. The barrier was designed with an 800mm wide trench, a length of 1km and varying depths up to a maximum of 20m, forming a large rectangle.

Bachy Soletanche built the wall using a cement-bentonite slurry wall technique. Cement was added to the bentonite water slurry just before installation into the trench.

Previous ground strata sampling found that to the north of the railway line a trench of around 14m had to be dug, dropping down to 20m along the south side of the track. This was required to allow Bachy Soletanche to reach the impermeable layer of mudstone.

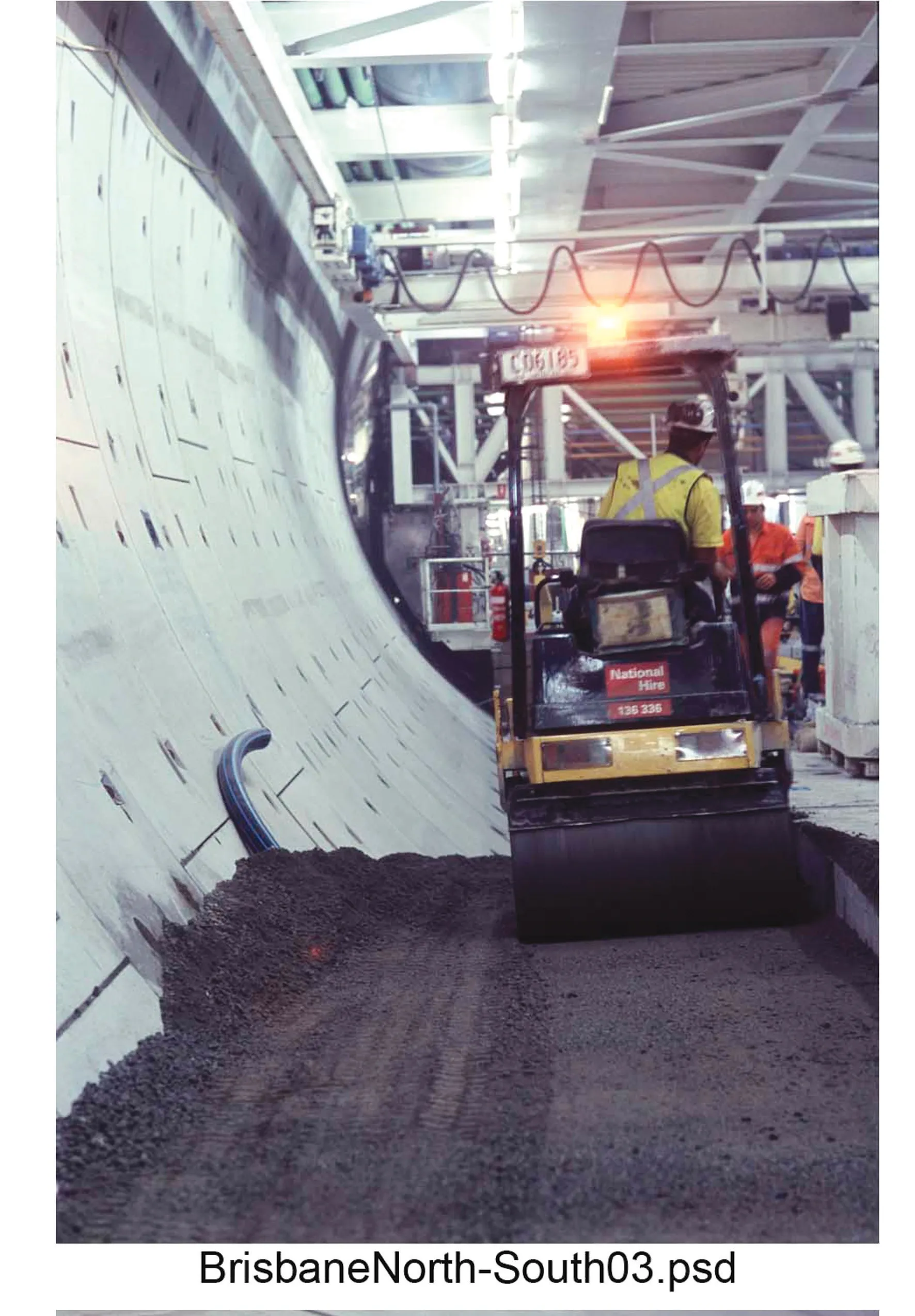

Due to the shallow excavations at the north side of the railway, a crawler excavator was used, working to a 14m depth. For the deepest sections of the slurry cut-off wall, to the south of the railway line, Bachy Soletanche used a crawler crane fitted with a clamshell grab to dig out the trenches. This was brought in from Spain especially for the project.

The road is being built within the impermeable barrier through the cutting under the railway line and rising out of the other side, so the road will ride over the impermeable barrier on the exit of the cut. The slurry wall provides a seepage-free rectangle and rainwater falling within the cut-off wall section passes through the highway drainage system. Once complete, the new road would provide a bypass to the west of Alderley Edge and Nether Alderley villages in Cheshire and will be 5.4km long.

Bachy Soletanche used its experience with slurry cut-off walls, a technique rarely used in Britain on road construction, to benefit a tricky section of the project.

The A34 bypass around Alderley Edge in Cheshire is a major UK road project. The link crossed existing infrastructure, in particular the main Manchester to London railway link.

Due to environmental reasons the bypass has to run under the railway line with the road level in a cutting and the road box formation 6m below the ground level at the Welsh Row section.

The location posed several challenges for

The major issue is that cutting through this area would draw down the high water table, which could have an affect on the structural integrity of the railway track. And should the water table have been altered in any way it could have affected the surrounding area by way of drying out wet areas.

One of the biggest challenges facing the designer was to overcome the problem and create a barrier, preventing water seepage to maintain the natural water table levels. Several options were examined including sheet piling or piled wall techniques, but the most cost effective solution to this problem was to create a slurry cut-off wall. A slurry wall is a non-structural barrier that is constructed underground to impede groundwater flow and is often used on land reclamation projects.

Bachy Soletanche, along with Birse Civils, Cheshire East Council and geologists planned the details. The barrier was designed with an 800mm wide trench, a length of 1km and varying depths up to a maximum of 20m, forming a large rectangle.

Bachy Soletanche built the wall using a cement-bentonite slurry wall technique. Cement was added to the bentonite water slurry just before installation into the trench.

Previous ground strata sampling found that to the north of the railway line a trench of around 14m had to be dug, dropping down to 20m along the south side of the track. This was required to allow Bachy Soletanche to reach the impermeable layer of mudstone.

Due to the shallow excavations at the north side of the railway, a crawler excavator was used, working to a 14m depth. For the deepest sections of the slurry cut-off wall, to the south of the railway line, Bachy Soletanche used a crawler crane fitted with a clamshell grab to dig out the trenches. This was brought in from Spain especially for the project.

The road is being built within the impermeable barrier through the cutting under the railway line and rising out of the other side, so the road will ride over the impermeable barrier on the exit of the cut. The slurry wall provides a seepage-free rectangle and rainwater falling within the cut-off wall section passes through the highway drainage system. Once complete, the new road would provide a bypass to the west of Alderley Edge and Nether Alderley villages in Cheshire and will be 5.4km long.