Months of detailed planning and client liaison ensured the 47.5m-long bridge decks, each containing 330tonnes of steel and 720tonnes of concrete, were successfully travelled to the site and lowered onto the abutments.

On-site civil engineering works were undertaken by the A14 Integrated Delivery Team,

a joint venture between

The original scheme called for erecting the bridge decks piecemeal using a crane. This would have involved closing the A14 for a number of weeks. Instead, the decks were constructed near the new bridge site and, using self-propelled modular transporters (SPMTs), travelled a short distance down the closed A14 to the abutments. This meant much less disruption to traffic. It also reduced project delays - SPMTs can better operate in high winds in comparison to cranes.

Meanwhile, instead of delivering the bridges as part-length paired-girders and then welded on-site, they were delivered as full-length single-girders – saving about three weeks. When on site, the single girders were braced together and handed over to the A14 Integrated Delivery Team before reinforced concrete was added.

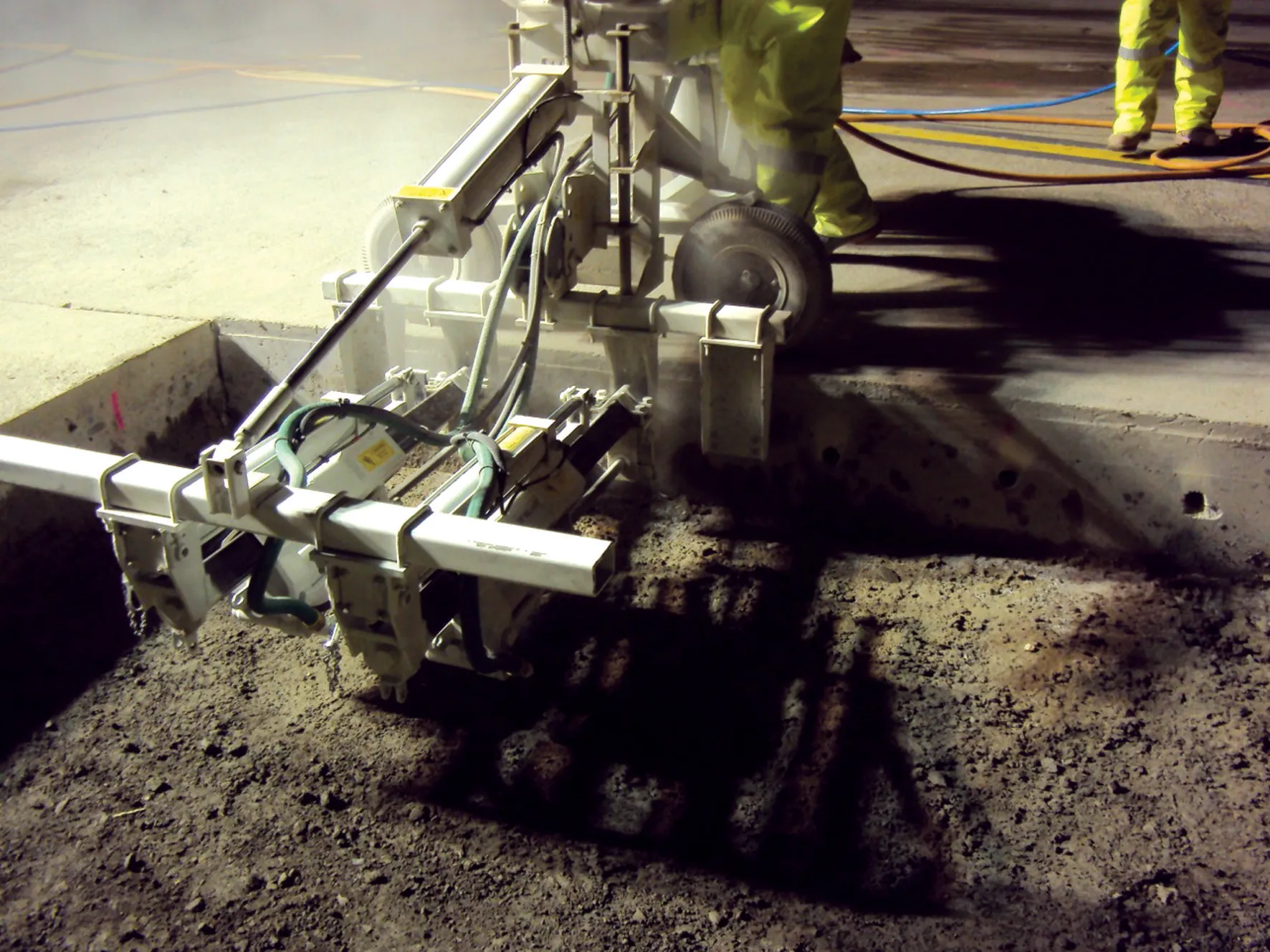

The A14 was closed to traffic at 9pm on a Friday to allow the sections of the existing A14 carriageway to be infilled and regraded to accommodate the SPMTs. The decks were then lifted from a series of trestles onto the SPMTs which eased them along to the abutments for lowering into position.

The bridges were installed during an 11-hour period and the road reopened by noon on Sunday – 18 hours ahead of schedule.