SACYR Chile is constructing a bridge on the new Northeast Access Highway in the capital Santiago, and when complete the 22.5km route will link the suburbs of Vitacura and Colina to the city. Acceso Nororiente, opening this year, is the fifth urban freeway in Santiago and stands out because of the challenges in the construction of its bridges ands tunnels.

February 27, 2012

Read time: 3 mins

Acceso Nororiente, opening this year, is the fifth urban freeway in Santiago and stands out because of the challenges in the construction of its bridges ands tunnels. The difficulties were extreme at ground level and the elevated sections required state-of-the-art technology, logistics and environmental damages mitigation measures throughout the project.

The Arquitecto Cruz Viaduct, which seems to float in the sky, has five large pier caps (770tonnes each, measuring 21m x 13m) that required one of the largest cantilever formwork systems ever used in Chile. With heights up to 45m, the columns were engineered to be hollow with a 0.5m thick wall. Each column is ovular in shape with two flat sides and 2.5m diameter ends.

SACYR selected

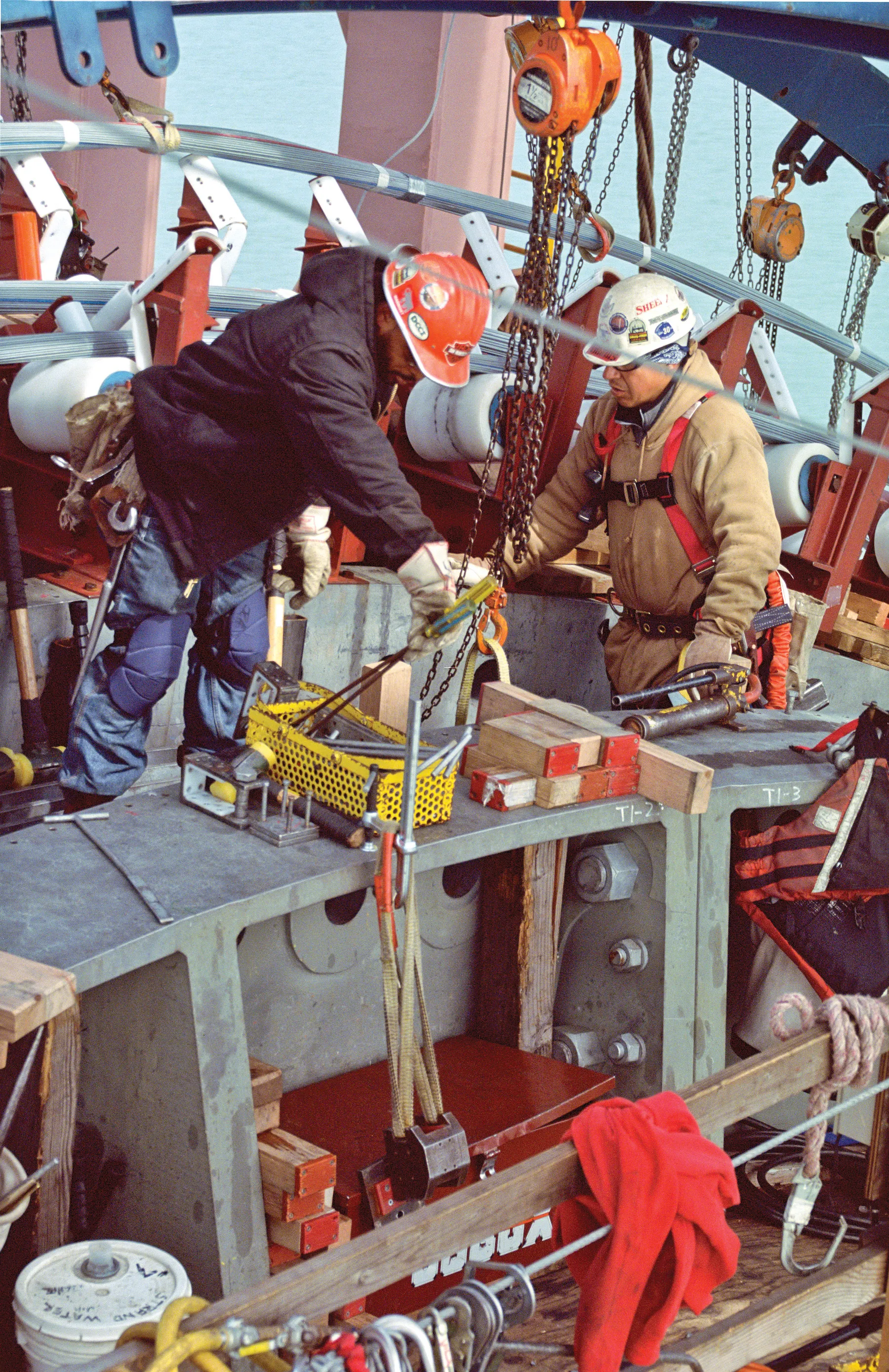

The EFCO Plate Girder system was used as main and secondary large beams and was located at different levels and directly below each cap, creating a base large and strong enough to install the E-Z Deck shoring system. Plate Girder shoring support structures were mounted more than 40m above and weighed more than 90.7tonnes.

On the first level, a 21.6m long Plate Girder assembly of 2.4m² panels acted as main beams, and rested on four SB-4 plus four SB-2 support brackets over both columns (separated at 12m) leaving a 4.8m cantilever on each side. Directly over these panels and transversely distributed there is a second line of beams made up with 1.5m x 2.4m and 1.2m x 2.4m double Plate Girder panels. Finally, to provide a support base for each EFCO E-Z Deck post, the contractor installed Efco's Super Stud as distribution beams. E-Beams cross over the Super Stud to make up the plywood working platform near the column.

Another 21.6m long Plate Girder assembly (2.4m²) panels acting as main beams rested over eight SB-4 support brackets distributed on both columns. Directly over these panels and transversely distributed, the Super Studs acted as spacers and also as secondary beams over which the plywood sheets were installed.

Continuous beams of EFCO Plate Girder were assembled on the ground near the column and long beam assemblies were lifted one by one into place.

"This project required a system that would support the incredible weight on relatively small columns. The EFCO systems were engineered and designed to work near the design capacity and performed beautifully," says EFCO.