The northern Spanish city of Bilbao looks set to benefit from a major tunnel construction project aimed at reducing traffic congestion on its vehicle clogged streets. The city is building a new underground metro section, Line 3, which will help carry commuters to and from the city's commercial centre and help reduce vehicle journey times on the surface.

This project is also making use of the latest piece of tunnelling equipment from Sandvik, the MT520 roadheader, a powerful machine designed and built at

February 10, 2012

Read time: 5 mins

The northern Spanish city of Bilbao looks set to benefit from a major tunnel construction project aimed at reducing traffic congestion on its vehicle clogged streets. The city is building a new underground metro section, Line 3, which will help carry commuters to and from the city's commercial centre and help reduce vehicle journey times on the surface.

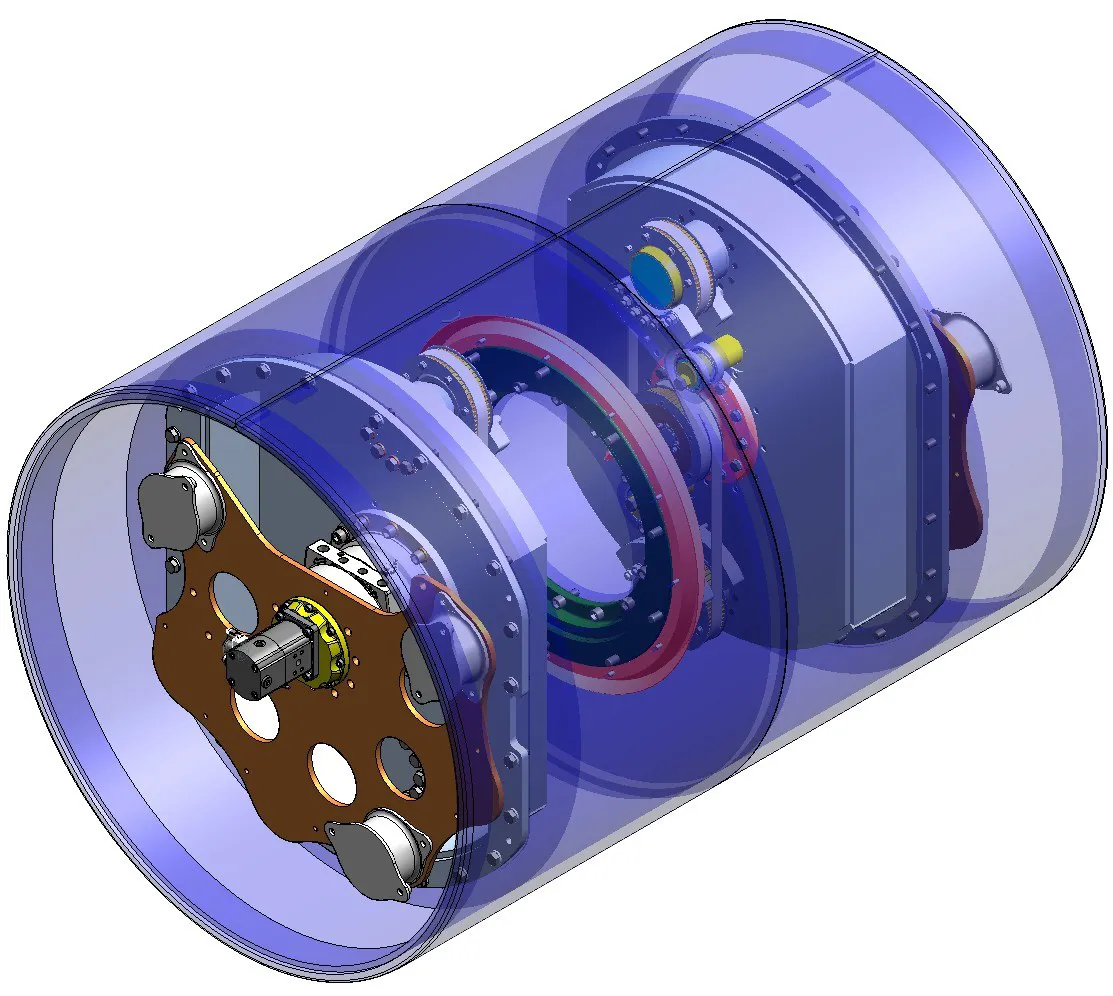

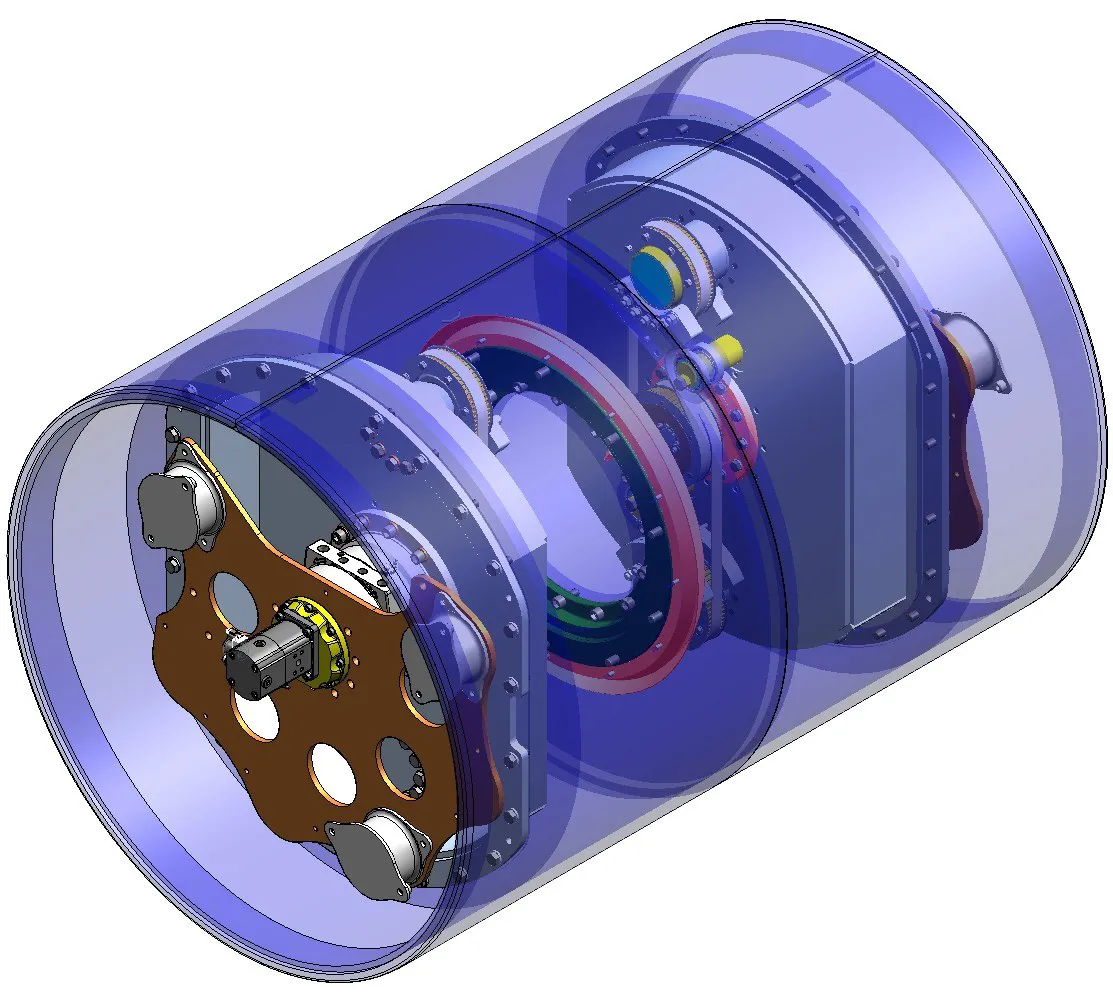

This project is also making use of the latest piece of tunnelling equipment from325 Sandvik, the MT520 roadheader, a powerful machine designed and built at the firm's plant in Austria. The MT520 slots into the Sandvik range between the existing 60tonne MT300 and 135tonne MT720 models and was developed to meet a perceived need for a mid-sized roadheader of around 100tonnes. Sandvik has already supplied two MT520s, with this unit operating in Spain and the other working at Sochi in Russia, where it is helping construct new road tunnels.

The new MT520 suits medium-long tunnel projects of 500-2,500m and with cross sectional areas of 40-90m² in harder rock conditions when fitted with onboard bolting, although the MT520 can cut wider tunnel drives when used in softer rock. It can be equipped with different cutter heads to suits soft, soft-medium hard, or hard rock conditions depending on the application. The target weight of the machine was 100tonnes originally but as the development project progressed it grew in size slightly and the final design weighs from 110-120tonnes, depending on the specification and options selected. The cutter head is driven by a 315kW motor and the machine can cut to heights of 7.1m in standard configuration and up to 8m with the optional extension module fitted. Meanwhile cutting width is up to 10.3m in standard layout and 10.8m with the extension module. The machine features active stabilisation to reduce vibration during operation and is designed for cutting rock with hardness of up to 100MPa.

In Bilbao the MT520 is being used to drive tunnels that will be 8.4m wide by 6.63m high, with bolting and shotcreting used to secure the drive, and cast sections then placed to complete the structure. Wider 58m² sections are driven for the seven 110m stations, again using roadheaders and overall these machines are being used, rather than drilling and blasting, because the tunnels are not deep and are comparatively close to the buildings above. TBMs were discounted early on as being also unsuitable and the project is using an array of roadheaders from different manufacturers for the tunnelling work, including a Sandvik MT720. The Bilbao project is being carried out two joint ventures, and, both of which comprise various partnerships between leading contractors.

Manfred Meier is senior engineer for roadheader research and development at Sandvik and he headed the project team that developed the MT520. Meier explained that the MT520 has been developed as a piece of equipment that can be used in a wide array of tunnelling application, "The whole machine is based on a modular design." He said that while the MT520 design was based on much of the existing MT720, the turret system has been reinforced so as to cope with the forces generated by the in-line cutting system. Productivity is said to be high and the machine can cut an accurate profile due to its stability and vibration damping. Meier added, "The loading table provides extra stability. We have the ability to cut almost vertically." Rock conditions vary hugely, as do tunnel projects but Meier said that for a hardness of 60MPa, the MT520 should achieve a productivity of some 36-38m3/hour. As tunnelling requirements vary so widely depending on the requirement of the project and the type of rock being excavated, the MT520 is offered with a wide option list in addition to the extension module. Customers can opt for either the standard transverse head which is better suited to harder rock of 50-100MPa, or an in-line type cutting head for softer rock conditions. The larger MT720 can cope with rock hardness of up to 160MPa but is less versatile than the MT520, with its wider option list. The in-line version of the MT520 is usually slightly lighter than the transverse model and Meier added, "In soft rock the in-line cutter head can have up to 20% more productivity. Profiling is definitely better with an in-line head." However he said that the MT520's transverse cutter head allows for better loading.Another important option is for a complete high pressure, water spray system piped through the cutting head, rather than the more conventional dust spraying equipment mounted on the cutting arm. The MT520 has a total installed power of 537kW and runs from a 1,100V supply at a standard 50Hz. However, a 160kW201 Deutz diesel power pack can be installed to maximise mobility and Meier said, "It enables you to move the machine when the electric supply is disconnected." Customers can also opt for a slewing belt conveyor to maximise truck loading capabilities as well as a water hose and supply reel system. A key option is for a complete bolting package, which can be mounted on the machine deck. This package suits applications where high productivity is required or where working space is limited as the MT520 can continue cutting while its own bolters be used to secure the roof. Other options include a directional control system, profile control and visualisation packages and automatic fire suppression equipment from Ansul. Fully-integrated dust extraction and an enclosed, air-conditioned cab ensure that the tunnelling team benefit from a comfortable working environment at the face.

With the MT520 now well-proven in the Bilbao and Sochi tunnelling projects, Sandvik hopes to find further customers for this highly versatile and productive tool. The tunnelling market is strong at present and there is a huge potential for the machine in road projects in Europe, South America and Asia in particular, a business where Sandvik wants to continue to strengthen its presence.

This project is also making use of the latest piece of tunnelling equipment from

The new MT520 suits medium-long tunnel projects of 500-2,500m and with cross sectional areas of 40-90m² in harder rock conditions when fitted with onboard bolting, although the MT520 can cut wider tunnel drives when used in softer rock. It can be equipped with different cutter heads to suits soft, soft-medium hard, or hard rock conditions depending on the application. The target weight of the machine was 100tonnes originally but as the development project progressed it grew in size slightly and the final design weighs from 110-120tonnes, depending on the specification and options selected. The cutter head is driven by a 315kW motor and the machine can cut to heights of 7.1m in standard configuration and up to 8m with the optional extension module fitted. Meanwhile cutting width is up to 10.3m in standard layout and 10.8m with the extension module. The machine features active stabilisation to reduce vibration during operation and is designed for cutting rock with hardness of up to 100MPa.

In Bilbao the MT520 is being used to drive tunnels that will be 8.4m wide by 6.63m high, with bolting and shotcreting used to secure the drive, and cast sections then placed to complete the structure. Wider 58m² sections are driven for the seven 110m stations, again using roadheaders and overall these machines are being used, rather than drilling and blasting, because the tunnels are not deep and are comparatively close to the buildings above. TBMs were discounted early on as being also unsuitable and the project is using an array of roadheaders from different manufacturers for the tunnelling work, including a Sandvik MT720. The Bilbao project is being carried out two joint ventures, and, both of which comprise various partnerships between leading contractors.

Manfred Meier is senior engineer for roadheader research and development at Sandvik and he headed the project team that developed the MT520. Meier explained that the MT520 has been developed as a piece of equipment that can be used in a wide array of tunnelling application, "The whole machine is based on a modular design." He said that while the MT520 design was based on much of the existing MT720, the turret system has been reinforced so as to cope with the forces generated by the in-line cutting system. Productivity is said to be high and the machine can cut an accurate profile due to its stability and vibration damping. Meier added, "The loading table provides extra stability. We have the ability to cut almost vertically." Rock conditions vary hugely, as do tunnel projects but Meier said that for a hardness of 60MPa, the MT520 should achieve a productivity of some 36-38m3/hour. As tunnelling requirements vary so widely depending on the requirement of the project and the type of rock being excavated, the MT520 is offered with a wide option list in addition to the extension module. Customers can opt for either the standard transverse head which is better suited to harder rock of 50-100MPa, or an in-line type cutting head for softer rock conditions. The larger MT720 can cope with rock hardness of up to 160MPa but is less versatile than the MT520, with its wider option list. The in-line version of the MT520 is usually slightly lighter than the transverse model and Meier added, "In soft rock the in-line cutter head can have up to 20% more productivity. Profiling is definitely better with an in-line head." However he said that the MT520's transverse cutter head allows for better loading.Another important option is for a complete high pressure, water spray system piped through the cutting head, rather than the more conventional dust spraying equipment mounted on the cutting arm. The MT520 has a total installed power of 537kW and runs from a 1,100V supply at a standard 50Hz. However, a 160kW

With the MT520 now well-proven in the Bilbao and Sochi tunnelling projects, Sandvik hopes to find further customers for this highly versatile and productive tool. The tunnelling market is strong at present and there is a huge potential for the machine in road projects in Europe, South America and Asia in particular, a business where Sandvik wants to continue to strengthen its presence.