Nurock Mixers has developed an innovative compact volumetric machine.

April 4, 2012

Read time: 1 min

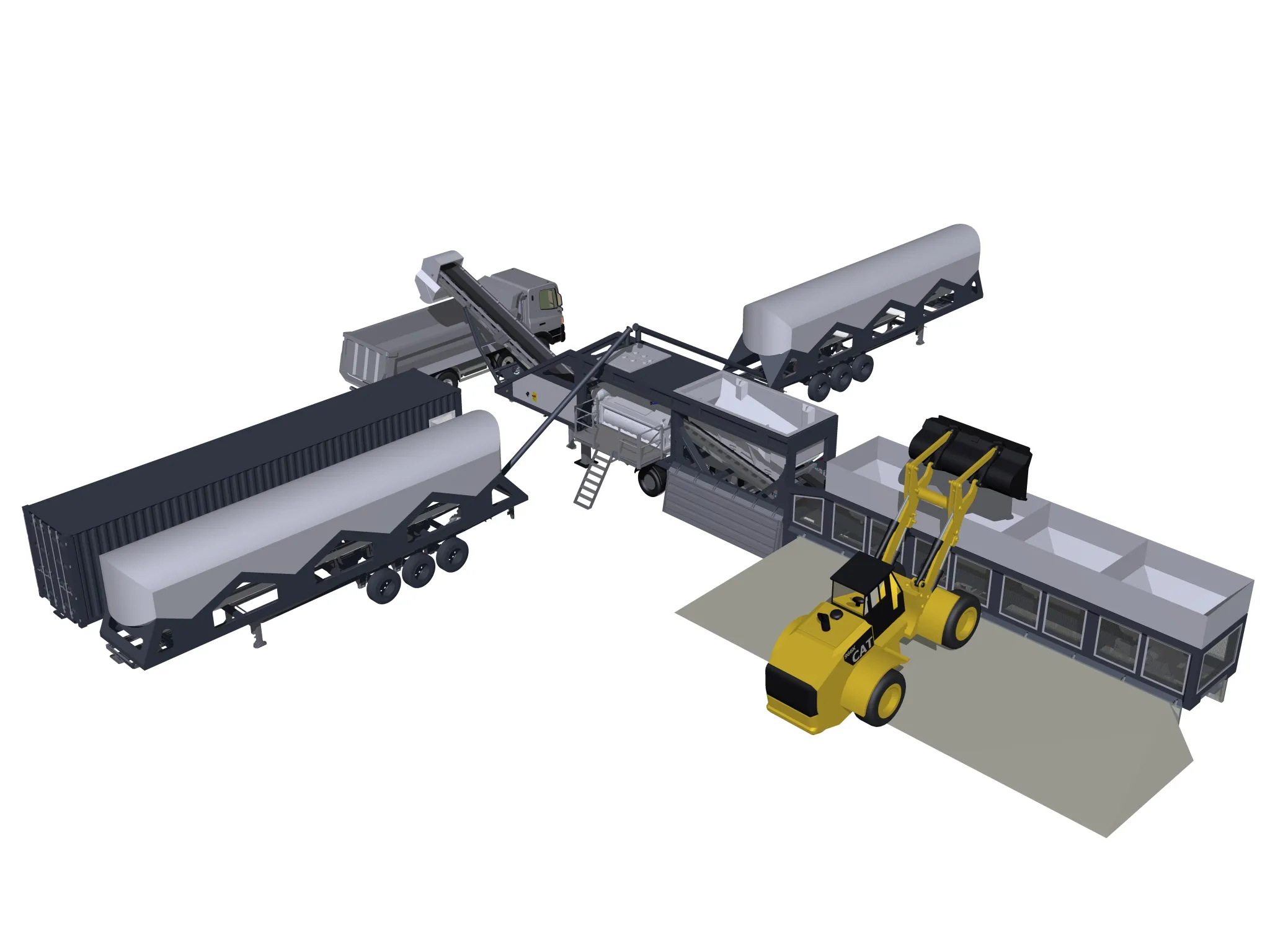

RSS2382 Nurock Mixers has developed an innovative compact volumetric machine. Called the NUVM1.5, this unit was first seen as a prototype at the 242 INTERMAT show in Paris in 2009 and is now being offered to the market. The NUVM1.5 can mix 1m³ of concrete in under three minutes using its combination of hoppers and hydraulics, while it can also produce screed, mortar or process recycled aggregates with a constant production rate at any cement content. Unlike competing mixers of this size and capacity, it is not a scaled-down derivative of a larger machine according to Nurock. This purpose-designed machine incorporates all the compartments for sand, stone and cement in one main hopper, rather than two, and stores water underneath, reducing its overall footprint by around 25%.

By replacing the chains, sprockets and mechanical components with hydraulics, the unit delivers a higher production rate as well as lower running costs and shorter downtime.

An optional onboard computer holds up to 50 preset mix designs. Highly versatile, the NUVM 1.5 is available in three versions, as a static unit for precast applications, as a trailer-mounted model for on-site use and mounted on a 7.5tonne truck for use in urban areas.

By replacing the chains, sprockets and mechanical components with hydraulics, the unit delivers a higher production rate as well as lower running costs and shorter downtime.

An optional onboard computer holds up to 50 preset mix designs. Highly versatile, the NUVM 1.5 is available in three versions, as a static unit for precast applications, as a trailer-mounted model for on-site use and mounted on a 7.5tonne truck for use in urban areas.