Automatic 3D machine guidance is a highly sophisticated area and a high level of expertise is often required to ensure applications of the advanced technologies work as desired. Fugro is a specialist firm that has gained experience using 3D guidance tools over many years and for certain tricky projects, Hexagon, the parent of Leica Geosystems, has turned to Fugro for assistance. For one difficult job in particular, Fugro's specialists were brought in at the request of an Icelandic contractor. The project ca

July 16, 2012

Read time: 3 mins

Automatic 3D machine guidance is a highly sophisticated area and a high level of expertise is often required to ensure applications of the advanced technologies work as desired. Fugro is a specialist firm that has gained experience using 3D guidance tools over many years and for certain tricky projects, Hexagon, the parent of 265 Leica Geosystems, has turned to Fugro for assistance.

For one difficult job in particular, Fugro's specialists were brought in at the request of an Icelandic contractor. The project called for the construction of a new runway for Akuryi Airport in the north of the country. Because the runway was to be surfaced with asphalt, the project faced a very limited time window when the work could be carried out. As its name suggests, the island of Iceland is a cold country and there is generally only one month in the year when the temperatures are moderate enough to permit asphalt paving.

The new runway is 2km long by 60m wide and to allow the work to be carried out the job had to be split into two. The first portion of the surfacing work was carried out in 2008 with the second half having been carried out this year.

The first task was to mill off the old surface using planing machines, with the contractor then laying the new asphalt in two layers. Because the surface is for an aircraft runway the contractor had to meet strict requirements for surface smoothness, skid resistance and compaction density. To ensure that the last factor in particular could be achieved, the contractor had to pay careful attention to the weather conditions, as asphalt cannot be compacted effectively to a suitable density when the temperature drops below 5ºC. This is because the asphalt cools too quickly for the compaction rollers to carry out their work.

To ensure that the paving and compaction operations could be carried out effectively within the tight time-frame, the 3D system has to take all the various parameters into account.

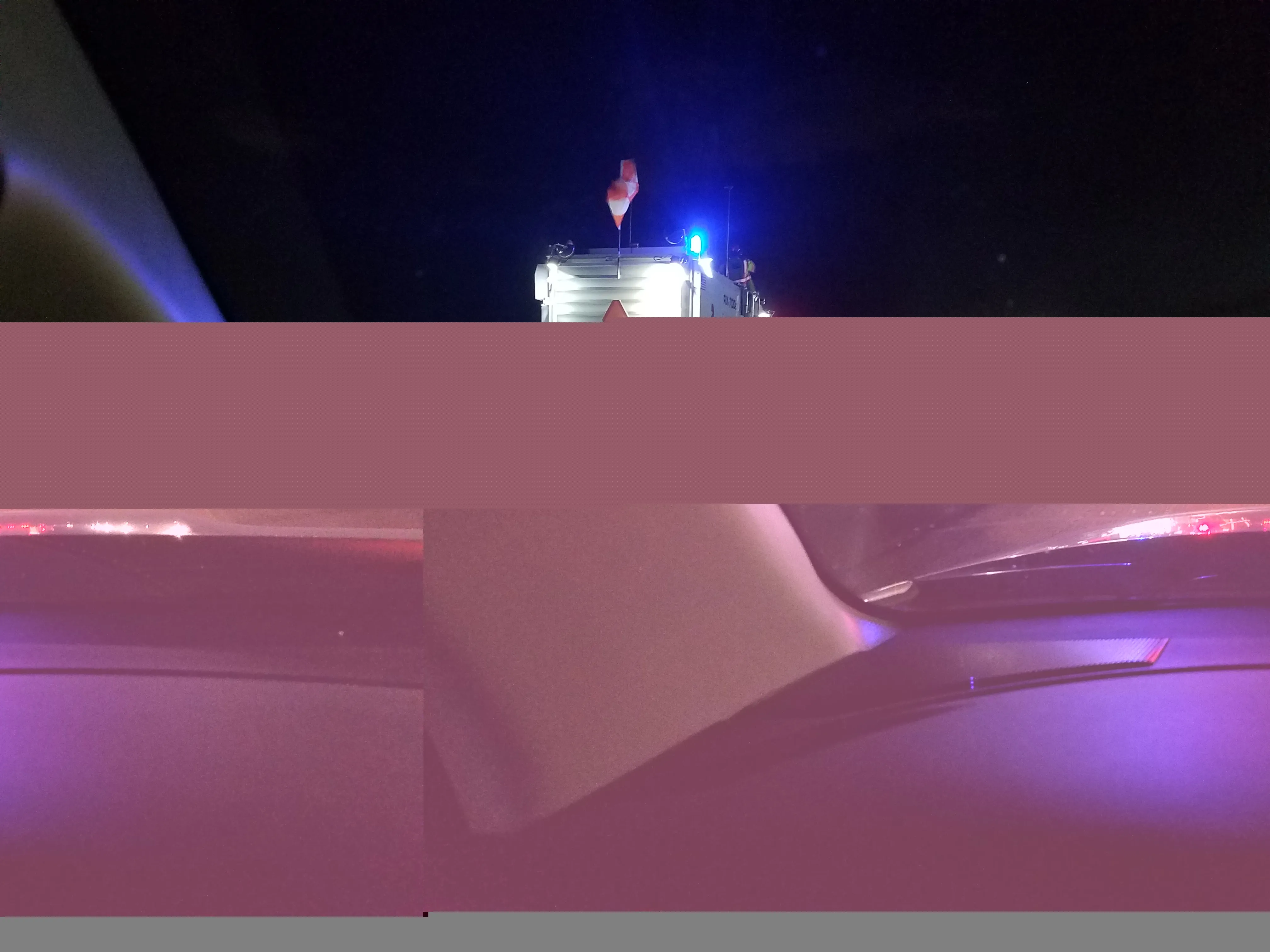

Fugro carried out the surveying activities necessary for automatic machine guidance. These included equipment testing, carrying out measurements and altering the design for the machines being used. Due to the short lead time, five surveyors worked continuously for three weeks in shifts for 24 hours/day. And the 24 hour working was possible because in Iceland, it does not get dark at night during summer. For one week the work could only be carried out during the night, to prevent disruption to daytime air traffic.

For one difficult job in particular, Fugro's specialists were brought in at the request of an Icelandic contractor. The project called for the construction of a new runway for Akuryi Airport in the north of the country. Because the runway was to be surfaced with asphalt, the project faced a very limited time window when the work could be carried out. As its name suggests, the island of Iceland is a cold country and there is generally only one month in the year when the temperatures are moderate enough to permit asphalt paving.

The new runway is 2km long by 60m wide and to allow the work to be carried out the job had to be split into two. The first portion of the surfacing work was carried out in 2008 with the second half having been carried out this year.

The first task was to mill off the old surface using planing machines, with the contractor then laying the new asphalt in two layers. Because the surface is for an aircraft runway the contractor had to meet strict requirements for surface smoothness, skid resistance and compaction density. To ensure that the last factor in particular could be achieved, the contractor had to pay careful attention to the weather conditions, as asphalt cannot be compacted effectively to a suitable density when the temperature drops below 5ºC. This is because the asphalt cools too quickly for the compaction rollers to carry out their work.

To ensure that the paving and compaction operations could be carried out effectively within the tight time-frame, the 3D system has to take all the various parameters into account.

Fugro carried out the surveying activities necessary for automatic machine guidance. These included equipment testing, carrying out measurements and altering the design for the machines being used. Due to the short lead time, five surveyors worked continuously for three weeks in shifts for 24 hours/day. And the 24 hour working was possible because in Iceland, it does not get dark at night during summer. For one week the work could only be carried out during the night, to prevent disruption to daytime air traffic.