Sandvik has announced a landmark technology partnership with IBM. The agreement between Sandvik Mining and Rock Technology and IBM will see the two firms jointly develop technology to deliver Data Driven Productivity and Predictive Maintenance services for rock excavation. The terms of the deal will see Sandvik and IBM working together on advanced analytics solutions to improve safety, maintenance, productivity and operational services of rock excavation equipment.

Sandvik points out that the growth in o

March 3, 2017

Read time: 2 mins

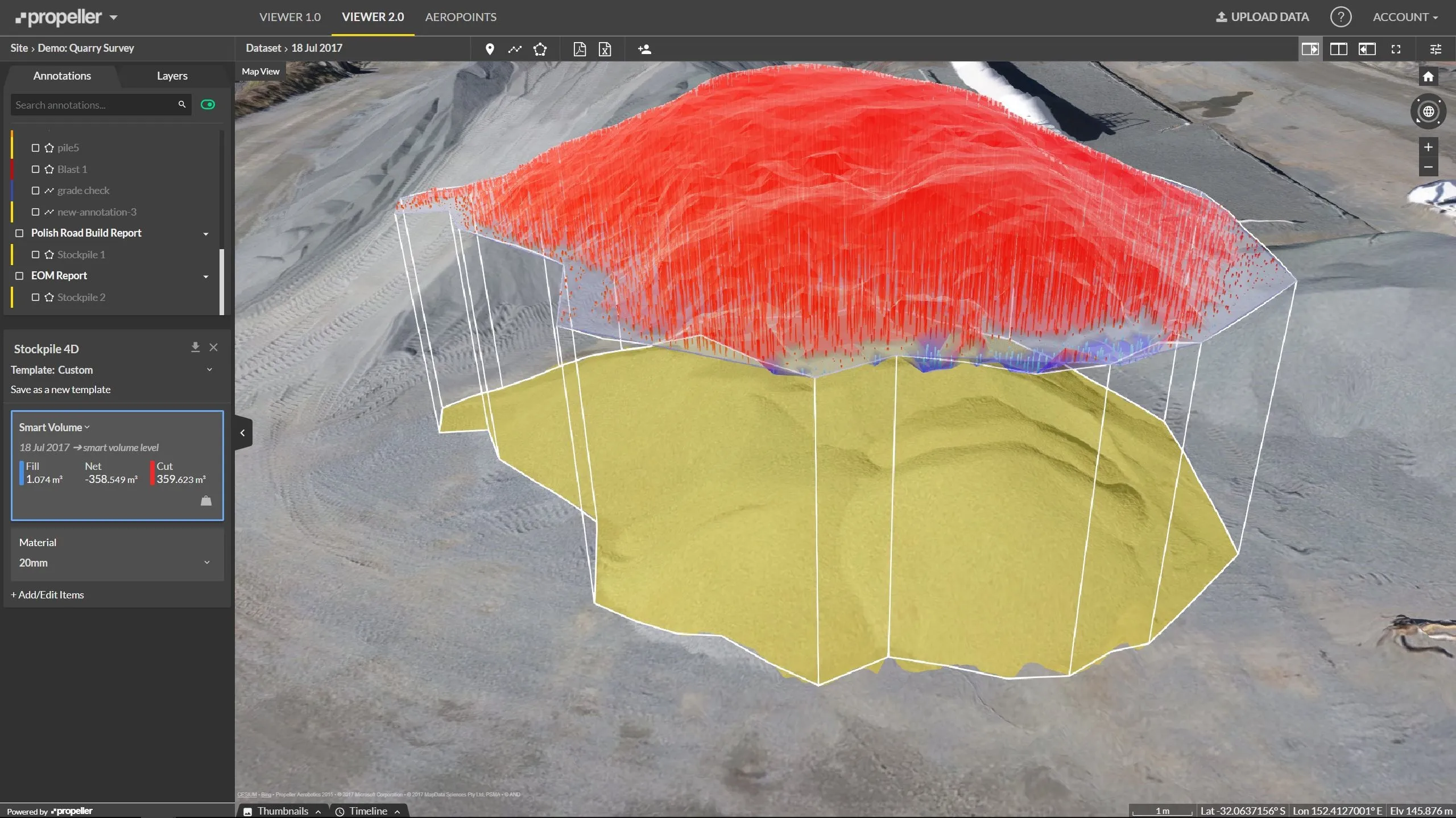

Sandvik points out that the growth in onboard instrumentation and data gathering capabilities in heavy equipment are presenting opportunities to employ advanced analytics and models. These can be used to identify and resolve productivity issues and improve process optimisation and performance.

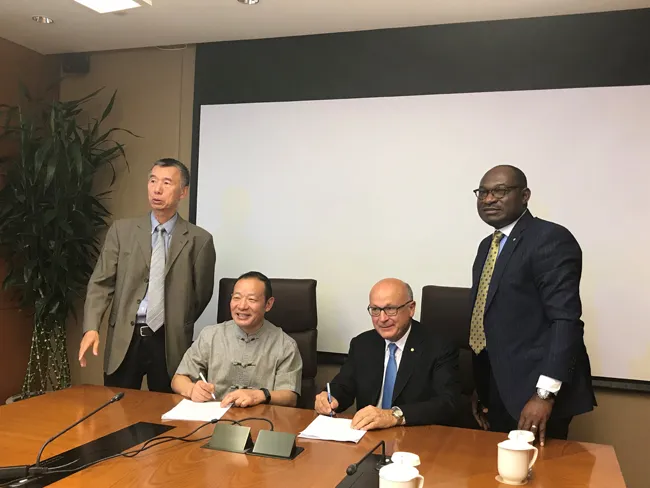

A Memorandum of Understanding has been signed by both firms with the intent to create market leading offerings in data driven productivity and predictive maintenance solutions. The two companies are already working jointly with selected customers to pilot the concept and commercialise specific solutions.

The IBM-Sandvik collaboration will involve the use of advanced analytics, remote monitoring and cognitive technologies. This will allow customers to combine equipment and application data from disparate resources and automatically analyse patterns in the data to improve performance and productivity.

This combination of information services, remote data collection and data analysis will enable increased effectiveness by increasing productivity, saving cost and reducing time wastage. It will assist in rock excavation by allowing well-informed decisions regarding production plans and maintenance schedules. It will also provide the opportunity to monitor and improve upon equipment utilisation.