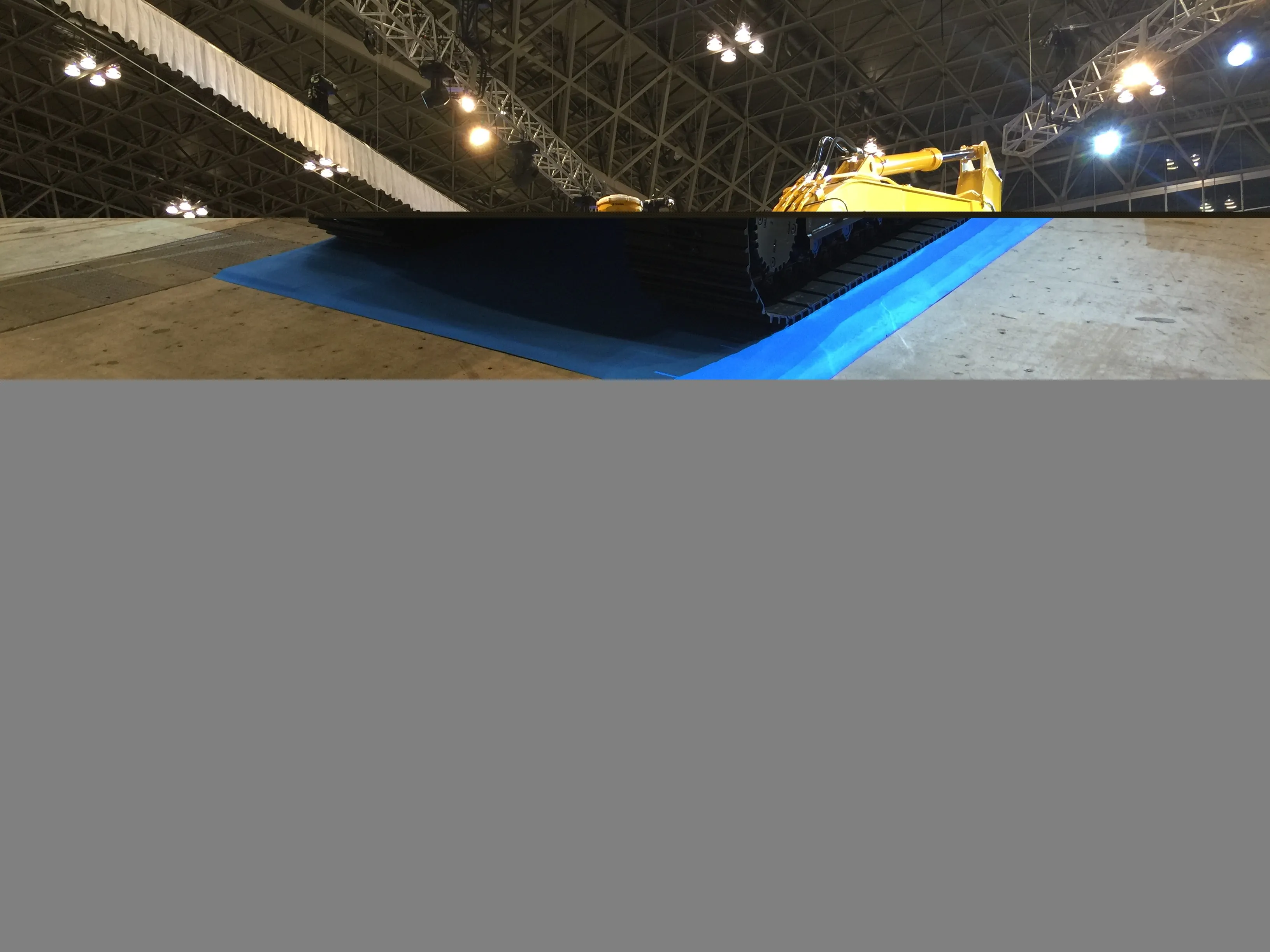

A new Caterpillar grade control system can be installed at the factory to certain Tier 4 Interim/ Stage IIIB emission compliant dozers, graders, scrapers and excavators. The technology improves operator efficiency and equipment performance while reducing the overall cost of a machine guidance system on site.

February 29, 2012

Read time: 3 mins

A new Caterpillar grade control system can be installed at the factory to certain Tier 4 Interim/ Stage IIIB emission compliant dozers, graders, scrapers and excavators. The technology improves operator efficiency and equipment performance while reducing the overall cost of a machine guidance system on site.

The system reduces set up time and cuts the need for surveyors to check and reset grade markings. When installed on a D8T or D9T dozer, grade control offers blade automation in three basic modes. These include a rough grade control for initial cut, grade protection as the site develops and grade control to ensure consistent blade loads and to limit track slip.The integrated auto carry feature ensures that the tilt function of the blade control remains with the operator. As long as the blade tips are above the site plan, the system will calculate blade load and adjust the blade.

The M Series 2 Cat motor graders have the cross slope grade control system, which provides automatic cross slope control capability and is compatible with all AccuGrade kits. Maintaining proper cross slope while grading ensures roads are built and maintained according to the intended design.

Grading a road to the desired cross slope requires grader operators to monitor both ends of the blade and blade position along with the grade in front of the blade and machine to anticipate where the cutting edge needs to be positioned. The cross slope system automatically controls one end of the blade and allows the operator to focus on the other side. The package also controls the blade slope, providing consistency.

The system uses factory installed sensors and standard machine components and a display in the cab allows the operator to set the target slope while displaying the current measured cross slope in real time. The system also indicates the direction of the blade slope.

The package can work as a stand-alone depth and slope system, while the laser receiver on the stick can be used with a contractor's laser transmitter for increased accuracy. The built-in warning feature provides audible and visual warnings.