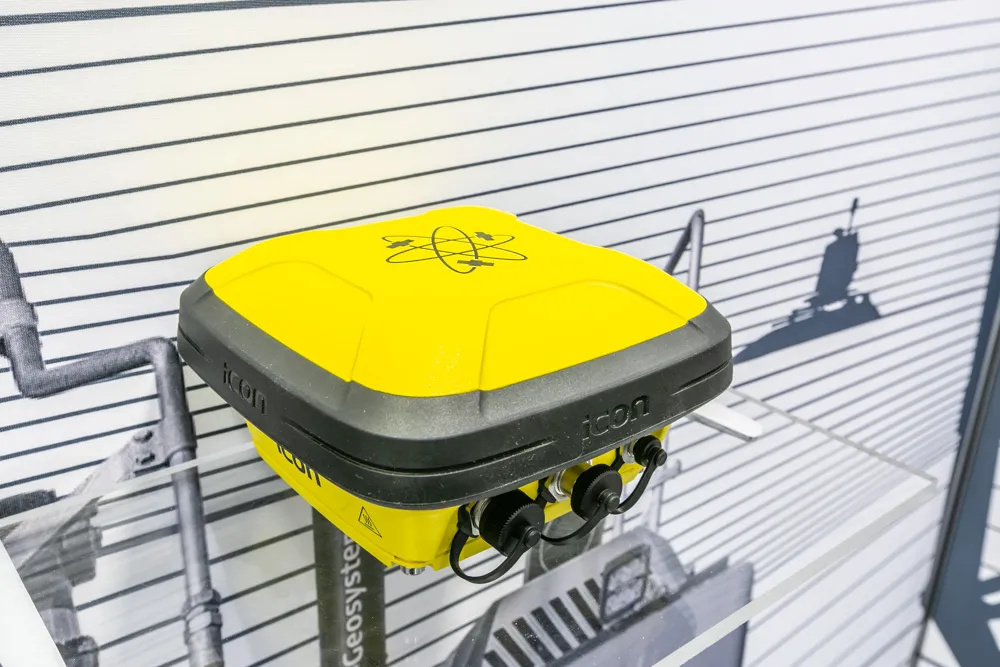

Leica Geosystems is widening its array of 3D machine control solutions with the introduction of its Leica iCON gps 120. This smart antenna offers customers a versatile machine control solution.

The nw Leica iCON 120 Machine Smart Antenna is integrated into the existing Leica MC1 solution platform and extends the machine control solution to more applications and machine types. Construction machines such as compaction rollers, which usually require only lower levels of accuracy without heading, can now be equipped with a tailor-made Leica MC1 machine control solution. This allows streamlined operations and consistent workflows between heavy construction equipment that vary in application requirements. Using the Leica MC1 machine control solution allows operators to carry out jobs more quickly and accurately, boosting fleet efficiency and reducing waste.

Construction customers can start with a single GNSS solution using a satellite-based augmentation system (SBAS) or HxGN SmartNet PPP service. If they need higher specifications, they can upgrade to an RTK solution with low or high accuracy by adding the communication unit Leica CR50. With a second iCON gps 120 Machine Smart Antenna, customers get a full high-accuracy dual GNSS solution with heading. A key feature of the design is that the antennas can be switched easily between Leica MC1 prepared machines due to the simple quick disconnect system.

“This solution is more versatile than our previous solution. You can take it from one machine to another and it’s perfect for rental machines. It’s an addition to our range, not a replacement for an existing unit,” according to Tommi Kauppinen, vice president, Heavy Construction, Machine Control Field Solutions at Leica Geosystems.