Atlas Copco claims that its high precision tunnelling (HPT) system will offer greater productivity and reduced costs in drill and blast tunnelling operations. The HPT system is a package with five options for use on drill rigs and other types of construction equipment. Advanced PC-based software allows a worksite office to provide operational support to Atlas Copco rigs equipped with the Rig Control System (RCS). The Tunnel Manager system can help plan, store and evaluate data for the drilling process. This

February 6, 2012

Read time: 3 mins

Advanced PC-based software allows a worksite office to provide operational support to Atlas Copco rigs equipped with the Rig Control System (RCS). The Tunnel Manager system can help plan, store and evaluate data for the drilling process. This data can be transferred to the drill rig, allowing more precise and efficient navigation. The package is offered in three versions, Tunnel Manager, Tunnel Manager Pro and Tunnel Manager MWD. The most advanced version allows recovered data to be analysed and is based on Atlas Copco's upgraded measurement while drilling (MWD) technology. Data can be used to determine properties including rock hardness, crack zones, allowing the driller to adjust the tunnelling process accordingly.

The sophisticated Rig Remote Access (RRA) system allows fast data transfer to and from the drill rig and also storages necessary information. When the drill rig is online, the recovered data can be made available to the contractor and engineers, with the information also being analysed automatically. In addition, the machine provides access for fault diagnosis or maintenance, while new drill plans can be uploaded to the rig remotely.

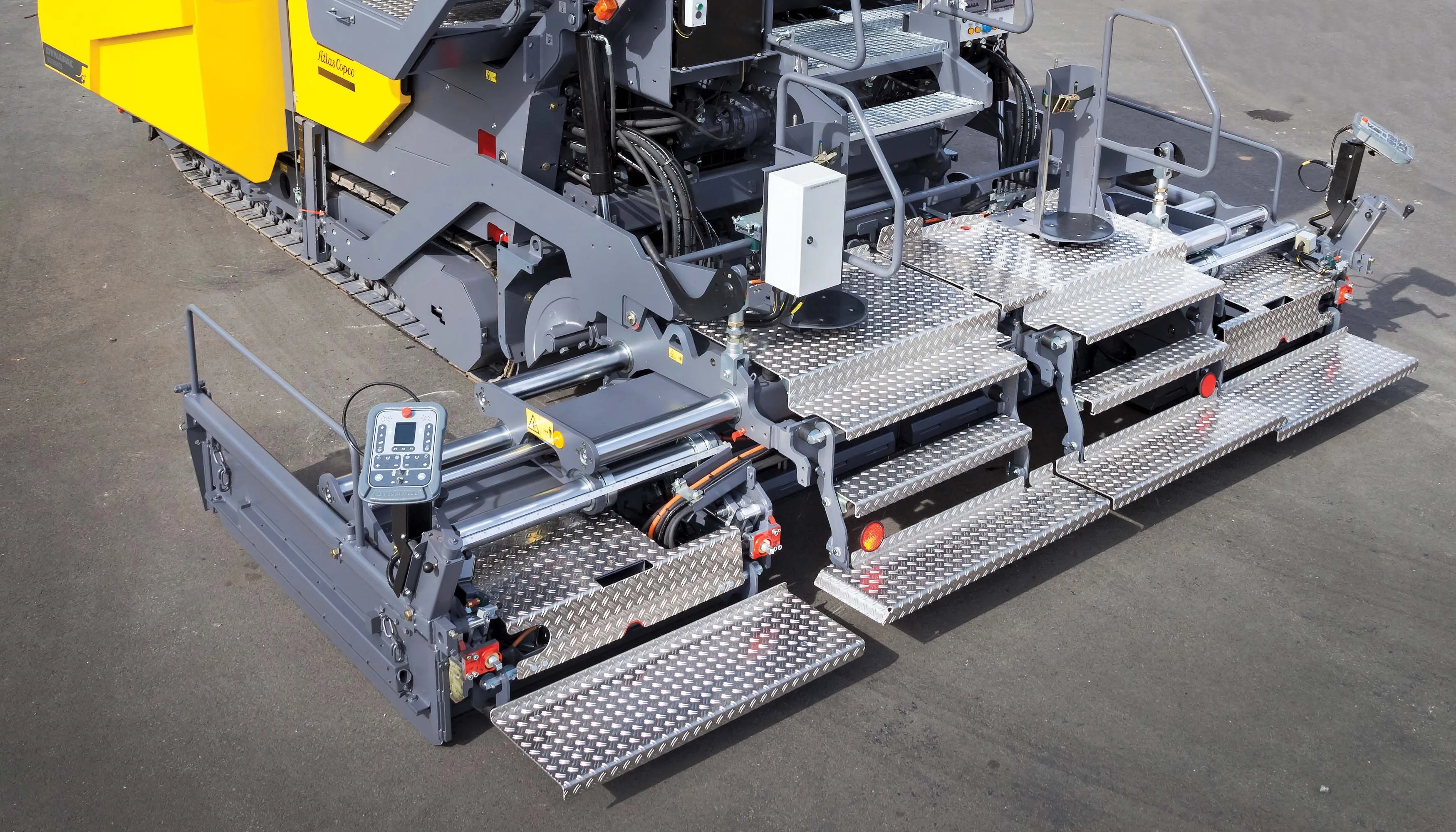

Using a tripod-mounted Total Station Navigation (TSN) system allows the machine to be guided with high precision to an accuracy of 10mm and this is also faster than manual methods, requiring just 5 minutes. According to Atlas Copco this fast set-up brings particularly good cost savings to the contractor and this alone can reduce costs by up to €100,000 (US$143,500) on a 2km tunnel for example. The benefits of more precise guidance bring further cost savings by reducing the risk of over/underbreak when blasting.

Using the firm's latest Tunnel Profiler package further improves efficiency and this sophisticated 3D-scanning system is said to work quickly and effectively. Each section can be scanned quickly, before drilling the next round and the system informs the rig operator of over/underbreak, speeding drill plan correction. Fast updates to drill plans can save up to 50mm in overbreak and in a tunnel with a 40m² profile this can deliver savings of €125,000/km.

Bolt Angle Indication is an additional software package that provides accurate guidance of rock bolting operations, ensuring that the bolts are correctly spaced. Using the system eliminated the need to mark the tunnel walls. The Bolt Plan Navigation software is another system that allows planning, guidance and logging of rock bolting duties. Using this in combination with the Total Station Navigation function, a rig can be rapidly manoeuvred into the right position, while data is recorded on cement used, how many bolts have been installed and their exact position.