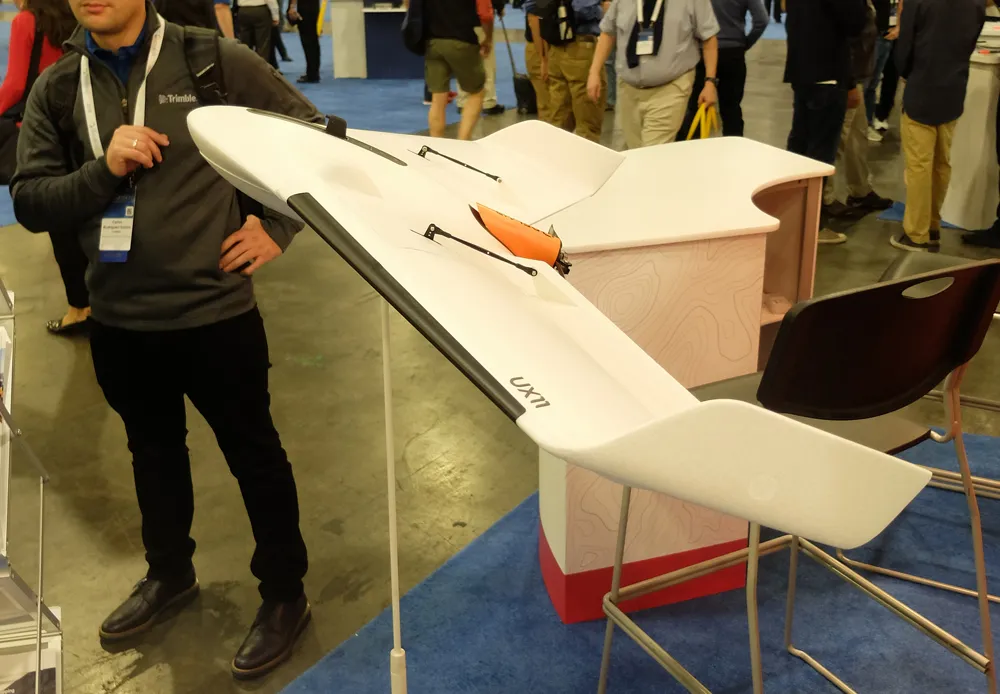

The tool allows users to generate maps and 3D models without the use of ground control points. The Trimble AP+ Air can be used for manned platforms as well as on unmanned aerial vehicles (UAVs). It can be used with almost all airborne remote sensors, including photogrammetric cameras, LiDAR, hyper and multi-spectral cameras, and synthetic aperture radar.

Using advanced compact, low-power hardware, the Trimble AP+ Air features dual embedded survey-grade GNSS chipsets, an onboard inertial measurement unit (IMU), an external IMU, and the all-new Applanix IN-Fusion+ GNSS-aided inertial firmware. It is configurable to support the Direct Georeferencing accuracy demands of low-flying UAVs to high-altitude manned platforms.

The firm is part of the Trimble Group and has taken advanced features of Applanix Direct Georeferencing and Trimble GNSS technology and packaged these into a compact and versatile solution, according to Applanix. The company adds that systems integrators can embed a hardware solution that can be configured to meet different Direct Georeferencing needs of a specific sensor type.

The Trimble AP+ Air is supported by the Applanix POSPac MMS post-processing software, which features CenterPoint RTX post-processing for centimetre-level positioning without base stations.

For LiDAR integrators, the Trimble AP+ Air is compatible with the POSPac MMS LiDAR QC Tools for computing boresight as well as adjusting the relative accuracy of the POSPac trajectory being used to generate the point cloud. For integration with cameras, the solution is supported by the POSPac MMS Photogrammetry Tools for computing boresight and performing camera IO quality control.