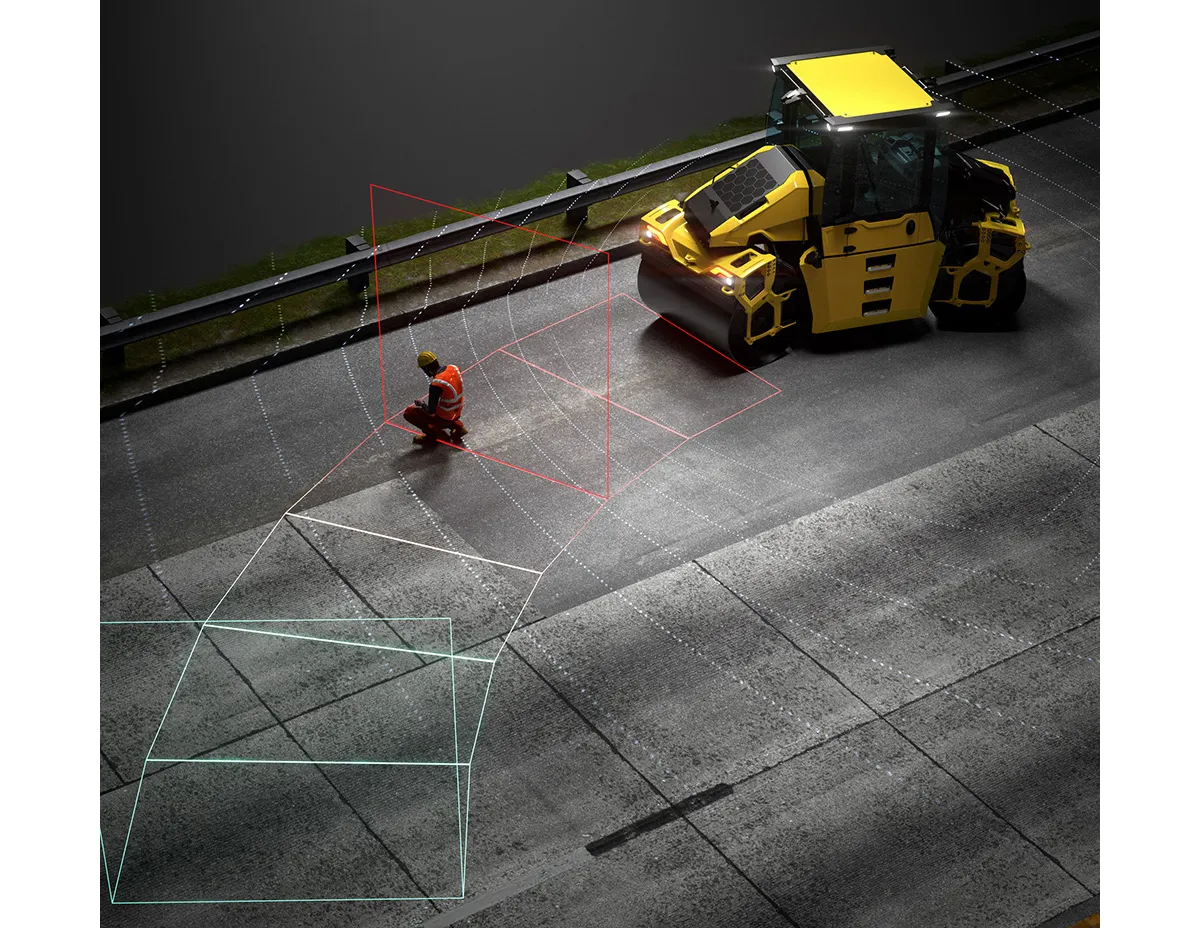

However, the upgrades include collision avoidance in hazardous conditions involving sensor-enabled machines, objects, and restriction zones.

Construction sites can be dangerous: heavy traffic, large equipment, poor visibility and blind spots all create the potential for accidents onsite.

The integrated collision-avoidance system and personal alert solution can help improve site productivity and safety. Providing better visibility, greater feedback to operators and field personnel minimises the risk of injuries, near misses and site shutdowns.

The Leica iCON PA10 is an accident-avoidance device worn onsite for 360 degree visibility of pedestrians around heavy equipment. The personal alert device creates multiple zones with up to 50m ranges with configurable warnings around any vehicle. The technology can predict potential close interactions between machinery and field crew, generating visual, audible and vibratory alarms to both operators and the pedestrians to avert potential accidents. Additional sensors can easily be installed on other moving objects and machines or to mark static infrastructure and avoidance zones. The resulting impact on blind spots and their human, operational and financial risks is significant. Safety awareness can thus become a keystone of how people, products and precious resources interact on successful construction sites.

Users of the Leica MC1 machine control platform can leverage their investments to run the new safety awareness solution. The Leica iCON PA80 integration will automatically alert the operator on the screen of the same device used for machine operations. This will increase awareness and immediate response regardless of whether the operator is in a dozer, excavator or any other heavy equipment. Leveraging the MC1 cloud enablement, incidents can also be logged and distributed to enable visualisation, analytics or reporting within a contractor’s existing safety management processes.