The SICK SicWave uses high-frequency 80 GHz free-space radar to overcome the limitations of low-frequency radar sensors or mechanical devices to achieve precision continuous level measurement.

The microwave pulses of the SICK SicWave sensors are claimed to penetrate through dust and material build-up to output accurate results. The SICK LBR SicWave is a bulk solids level sensor with a range of up to 120m. This can be used for continuous level measurement in production of products such as cement, concrete and gypsum for crushers and belt transfer, as well as for silos for storing products.

The firm claims that this technology can be used to manage the supply of bulk solids in storage vessels. It offers accurate level measurement using non-contact technology and is not disrupted by the presence of dust or build-up of residue, or by other obstructions in the vessel.

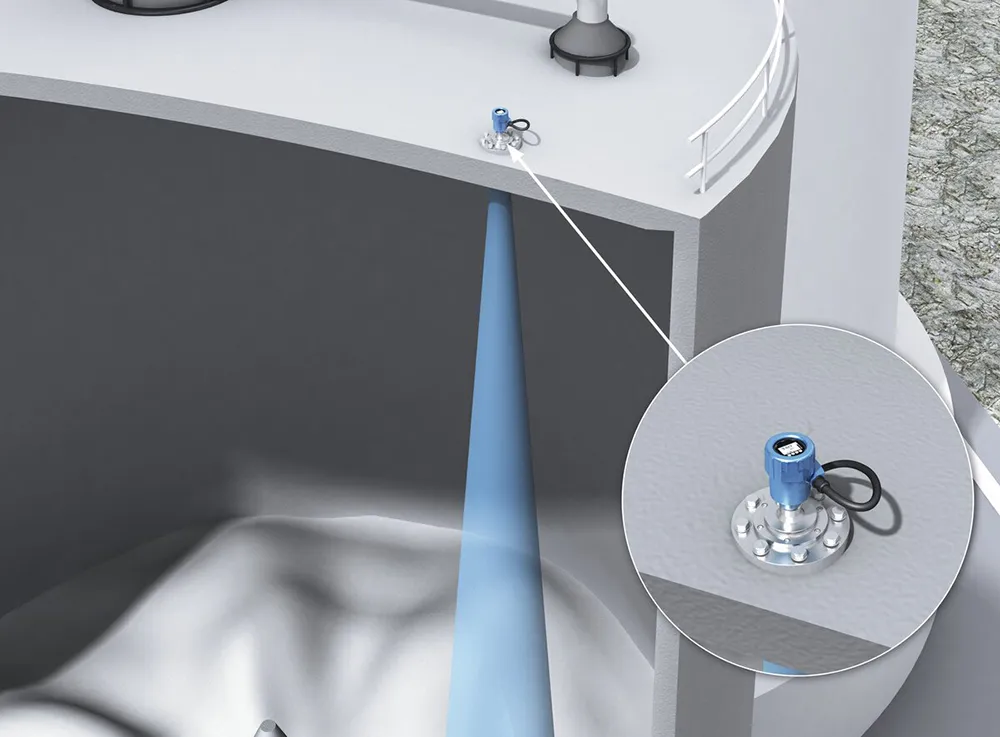

Positioned at the top of a silo, or over a heap or bunker, the SICK SicWave sensor sends a narrow beam of microwave radar pulses and uses the time-of-flight principle to return a high-quality signal even at long ranges or extreme temperatures and pressures. The SICK SicWave 80 GHz free-space radar sensors are a thousand times more sensitive than previous generation 26 GHz radar technologies ensuring high availability in challenging environments with minimal maintenance. The narrow field of view avoids the potential for false signals caused by deposits on walls or by obstructions inside the vessel.