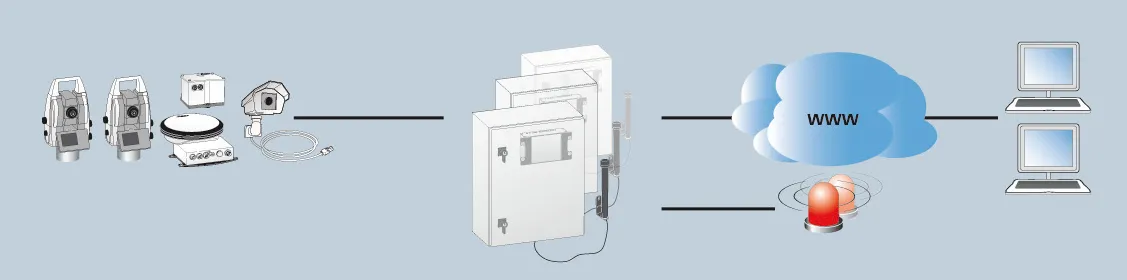

Leica Geosystems says that its latest package offers an efficient solution for monitoring communications. The updated GeoMoS v5.1 monitoring software features M-Com, which can integrate total stations, GNSS receivers and antennae, geotechnical sensors, software, and IT communication infrastructure. In addition the revised Leica GeoMoS v5.1 also supports the latest Microsoft Windows 7 operating system. The firm says that this package is easy to install and use, while increasing the mobility of periodic or sh

February 6, 2012

Read time: 2 mins