The POSPac Trimble Post-Processed CenterPoint RTX (POSPac PP-RTX) correction service has been enhanced for use with UAVs flown within Trimble RTX Fast service regions. This is now available on a subscription basis within the latest release of POSPac UAV 8.4, Applanix GNSS-aided inertial post-processing software. The POSPac PP-RTX correction service supports the generation of cm-level position solutions for short duration UAV trajectories without using local base stations. Final data is available within minutes of completing a mission.

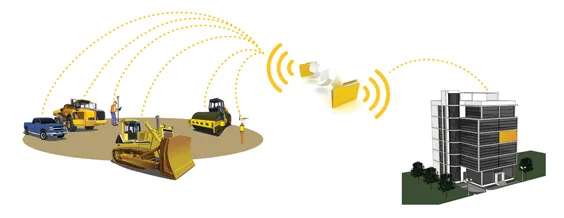

POSPac PP-RTX works with the Trimble APX UAV Series of board sets. This GNSS-inertial OEM solution is designed to reduce the cost and improve the efficiency of mapping from small UAVs. The package comprises a single OEM board containing a precision GNSS receiver and inertial sensor components plus post-mission Differential GNSS-inertial office software. The Trimble APX UAV eliminates the need to survey extensive Ground Control Points (GCPs), and reduces the amount of sidelap required to be flown, increasing the area flown/mission.

The POSPac UAV post-processing software processes data logged from the Trimble APX UAV series of board sets. The system can produce accurate position and orientation data from a LiDAR or camera flown onboard a UAV. The POSPac PP-RTX service uses the same data generated by Trimble RTX real-time correction services, which models precise satellite orbit, clock and atmospheric information. The POSPac PP-RTX service is available now through the Applanix sales channels.