In Denmark’s northern Jutland,

The

Preliminary ground investigations were made in 2013 and work started in 2015 with completion set for 2018. The motorway will connect the north-west of Jutland to a larger motorway network that accesses Denmark’s southern motorways and allows fast access to the rest of Europe.

Around 4 million m3 of soil has been excavated to form a cut through the landscape. It has given archaeologists a unique chance to explore the history of the ancient arterial road between Herning and Holstebro.

Leica Geosystems’ 3D machine control solutions are used for digging the search trenches to get a sideways and layered view of the deposits. This establishes if there are archaeological objects or material in the area and places them in chronological order.

Up to 600 people have been working on site. Leica Viva GS12 GNSS antenna together with the Leica CS15 controller automatically and precisely maps the findings. Archaeologists have on average made a finding for every 500m of digging. Objects have included a prehistoric sword dated around 600AD.

Glenn Lautrup is a foreman for MJ Eriksson Construction company that has the contract for 8km of the motorway near the village of Tvis. Products from Leica Geosystems are used on the entire project, both in the form of machine control solutions and products for grade checking and as-built documentation, explains Lautrup, who has worked on the project since August last year. On a typical day there are 10 dumpers, seven excavators, two bulldozers, one grader and three rollers as well as around 30 workers on the cut-through.

Up to 25% of the total budget for the motorway has been reserved for the preservation of nature. Around 650,000m³ of material has been excavated from nearby lakes for building the motorway. In the future, the lakes will be rehabilitated to create marshes and other lake areas. Several water channels and fauna passageways for hares, mice and frogs have been established. A 50m-wide fauna bridge - the largest of its kind in Denmark - has been built to allow red deer safe passage over the motorway.

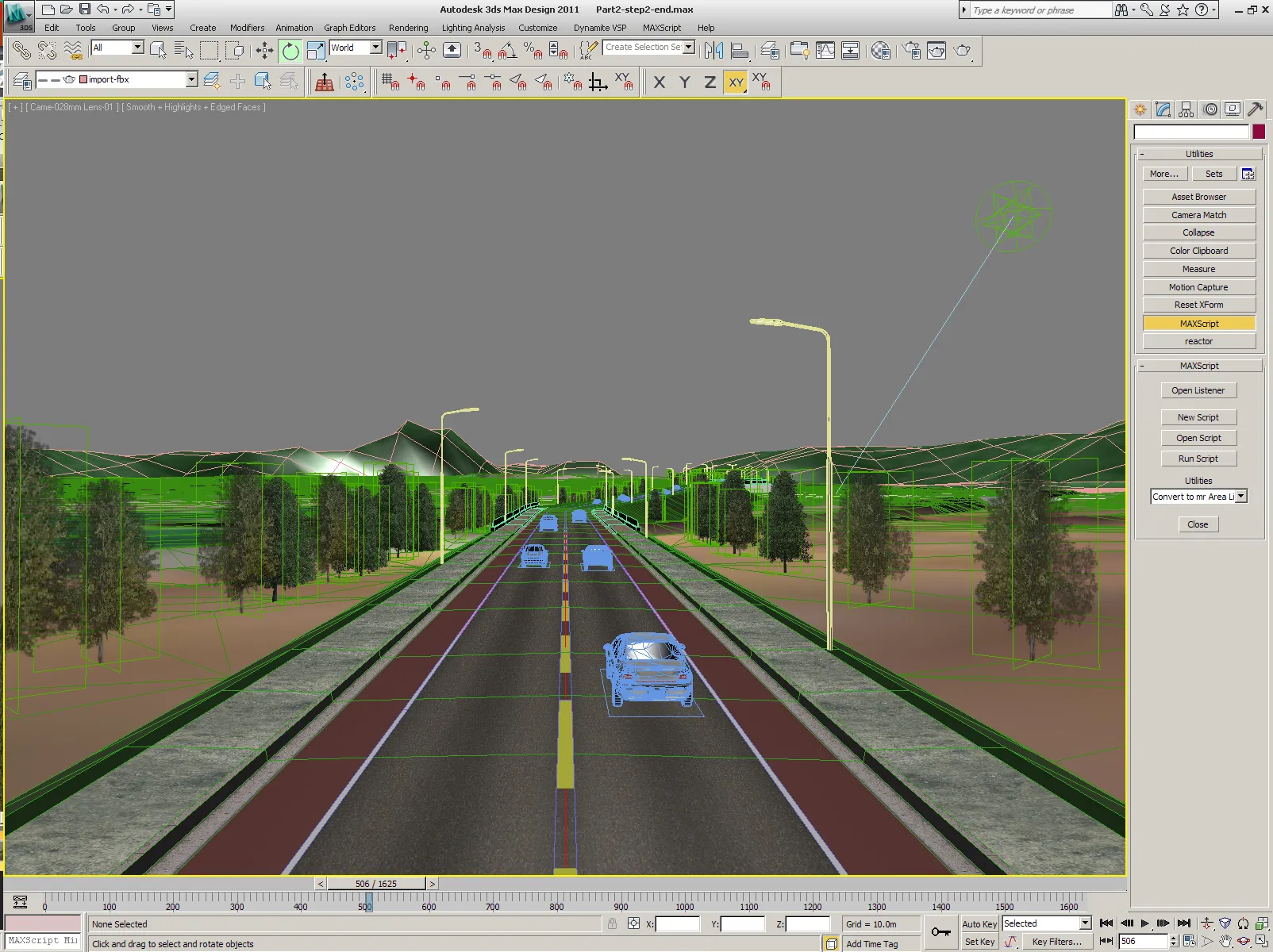

Leica’s iCON gps 60 SmartAntenna is used for grade checking. Line Christensen is an engineer working with data preparation at MJ Eriksson’s office in Holstebro. Using Leica iCON office software, she prepares road models that are loaded into the machine control solutions. “I receive the

“For this project, we are currently working on the 13th version of the file because there have been many changes to the project. I then use the Leica iCON office software to transform the AutoCad file to create triangulated files for the machine control solutions. Afterwards, I upload the file to Leica ConX, call the machine operator and tell him that there is a new updated file available.”

Line says that she visits the project daily to gain an understanding of what the operator needs in order for her to improve the preparation of files for them.

Heine Vendelbo is one of the MJ Eriksson operators who are in contact with Line. Vendelbo uses machine control systems on excavators, bulldozers and graders. He has been using machine control since 1985 and was one of the first people in Denmark to implement GNSS (Global Navigation Satellite System) in the heavy construction industry. On the current project Vendelbo uses his

“I’m 100% dependent on machine control in my daily work,” says Vendelbo. “Before the implementation of machine control, I would have a surveyor measure the area and place pegs and strings, all the while keeping a tight watch on my work. Now, I just load the file with the 3D model that I receive from Line Christensen into the machine control solution, and I can then do all the excavation alone just by following the model. If there are changes in the project, I simply delete the file and load the new version into the panel.”