The 2D Machine Guidance option will include a Sumitomo-designed user interface, using the integrated machine display panel in the excavator cab. The 2D Machine Control factory fit option includes an

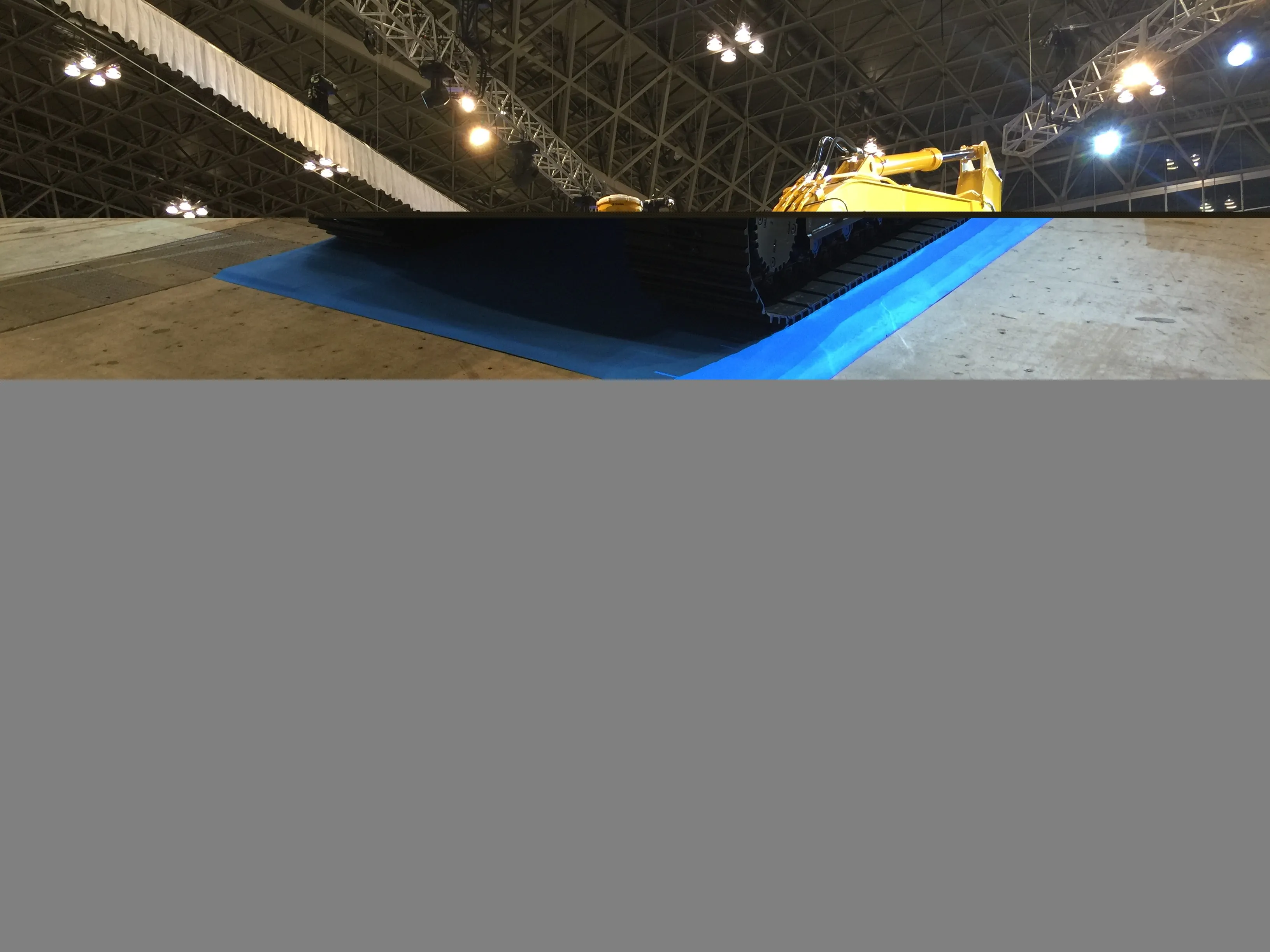

Zhengzhou Yutong Heavy Industries is the first Chinese manufacturer to offer the Trimble Ready package for dynamic compaction applications. The two firms have worked jointly to integrate the Trimble DPS900 Machine Control System onto Yutong’s dynamic compaction machines.

The DPS900 System uses real-time navigation and automatic recording and allows the operator to use a display to position the machine at the precise compaction point. The system automatically records the number of drops and the total displacement of each point. This new technology can improve productivity, avoid rework, and reduce the number of on-site construction workers needed, while boosting quality and safety.