Bergerat Monnoyeur is committed to supplying Caterpillar customers with a set of services based on full fleet digital connectivity, artificial intelligence and augmented reality.

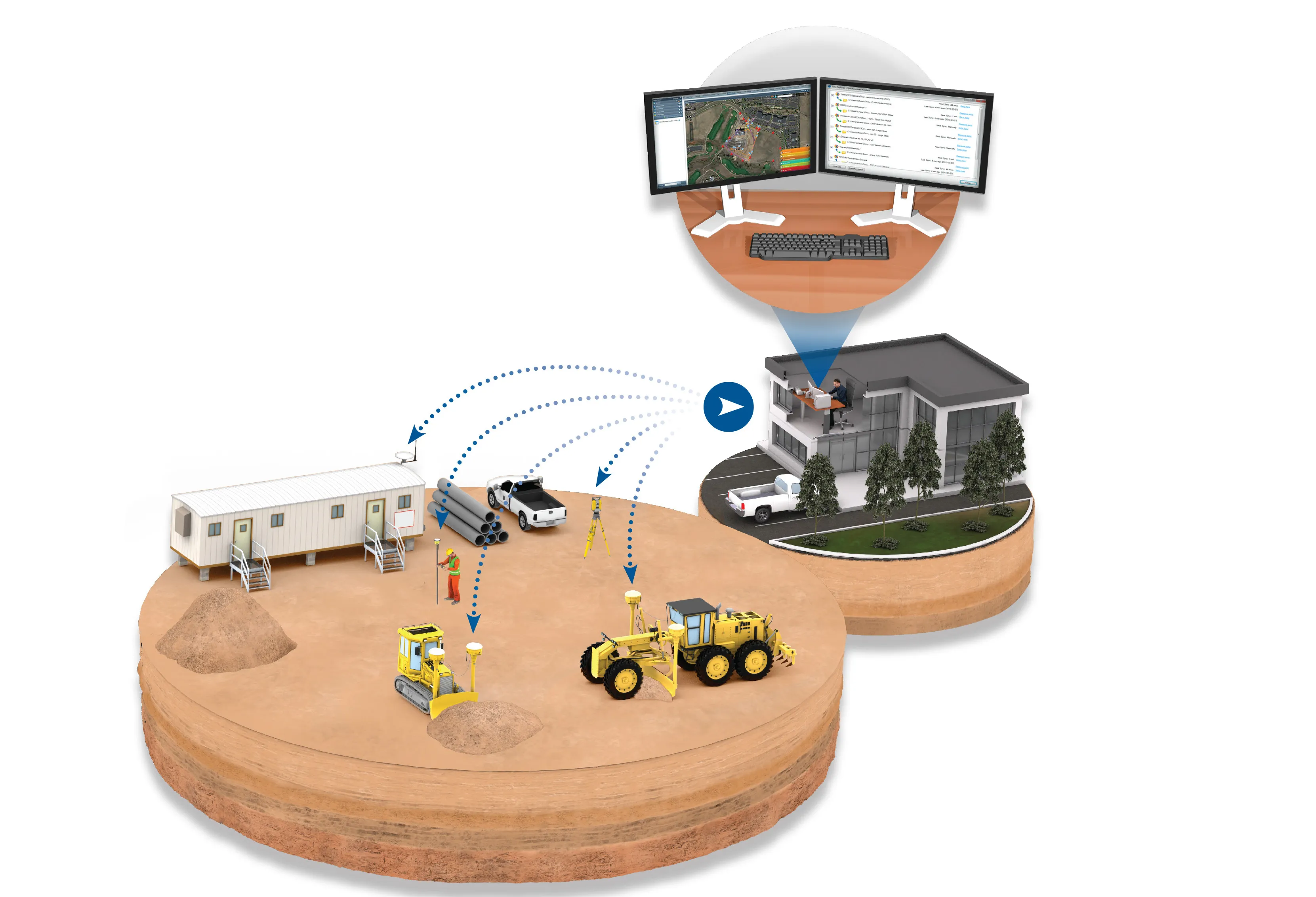

These new technologies offer access to remote diagnostics, allowing for informed predictive and preventive maintenance. Customers can also access the Bergerat Monnoyeur customer area, an e-commerce site for spare parts and mixed fleet data reports via VisionLink. The data is formatted by automatically sending a standard monthly report per machine with estimated fuel consumption, idle speed, carbon footprint and event code.

Thanks to this digitalisation of services, Bergerat Monnoyeur customers have the tools and support to help improve their productivity and reduce their fuel consumption and carbon footprint.