The company is also keen to develop further partnerships, building on the success of its existing agreements. Fosburgh commented, “We have long term partnerships, if you look at Caterpillar and Microsoft, we have been working with them for years.”

The firm is delivering major cost and efficiency benefits for its customers, and not just in construction. Trimble’s tools for the trucking sector are helping reduce operating costs and also boost safety. In-cab monitoring tools are helping identify causation in crashes. Fleet managers can also evaluate in-cab footage and telematics information and use this to identify the 10% or so of drivers who experience around 50% of the traffic incidents and also help deliver training to improve their performance.

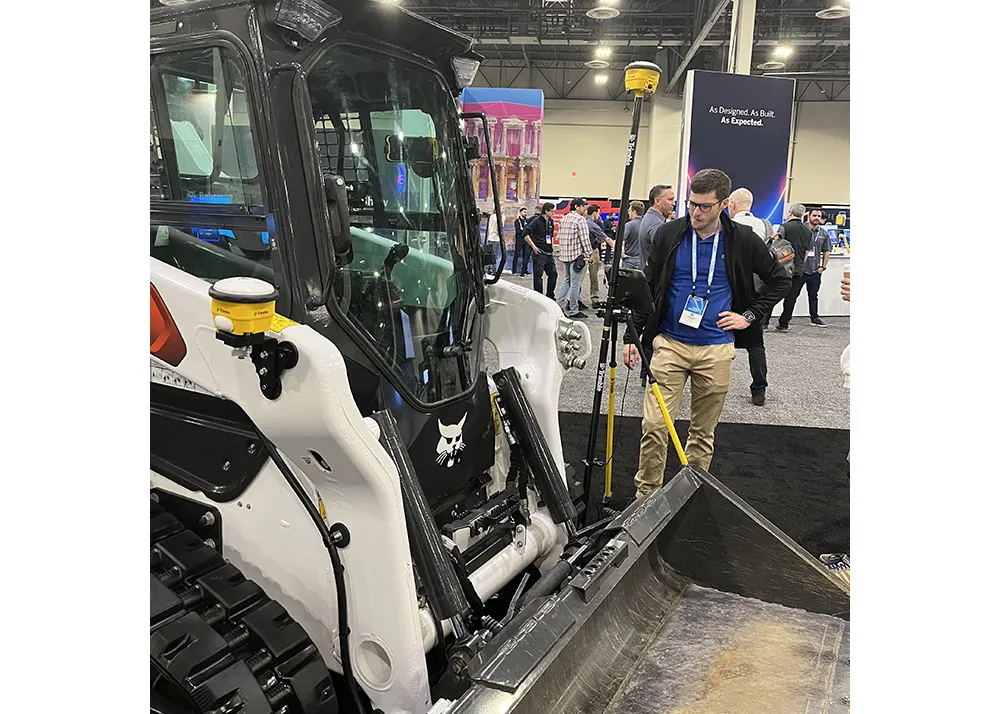

Innovative tools now coming from Trimble include the Catalyst package, which allows a phone or tablet to feature accurate positioning for use in construction applications. Catalyst is a software tool that can run on a smartphone and deliver millimetre accuracy, with the package also including a more efficient aerial mounted on a portable pole. By taking base station locations from around the world, this addresses the limitations of GPS and delivers RTK level accuracy on a smartphone.

Looking ahead, Trimble will keep its flow of technology solutions coming. And some of its customers are actively working with the firm on new projects that are helping reduce costs and boost efficiency.

Trimble's new tools in machine control technology

Trimble is focussing on making a difference at a corporate level, developing a process of positive change within its structure. The company aims to be inclusive and develop new solutions for its customers, while bringing in a wider range of personnel within its organisation. Bryn Fosburgh, vice president and executive committee member said, “What we have found in industry is that collaboration is needed. Collaboration is a key part of our values. Diversity is our strength.”

November 10, 2016

Read time: 2 mins