What’s the best way to get technology to the end-user? Topcon believes it has the answer with the 2014 edition of the Topcon Technology Roadshow, previewed for industry editors this week in Livermore, Calif.

April 10, 2014

Read time: 2 mins

First Published by Construction Equipment

What’s the best way to get technology to the end-user?

“Only 20% of contractors are using machine control today,” said Topcon president and CEO Ray O’Connor. “How do we get the message out to the other 80%? People have to experience it themselves. Getting it to the masses takes education. Bringing educational information about machine control and the benefits of it is very important.”

Hence the company’s Roadshow will travel more than 36,800km across the U.S. and Canada in a custom-designed 18-wheeler that expands into a 1,524m2 “solutions center” containing interactive displays of the latest positioning technologies in construction, surveying and GIS, and AEC professions.

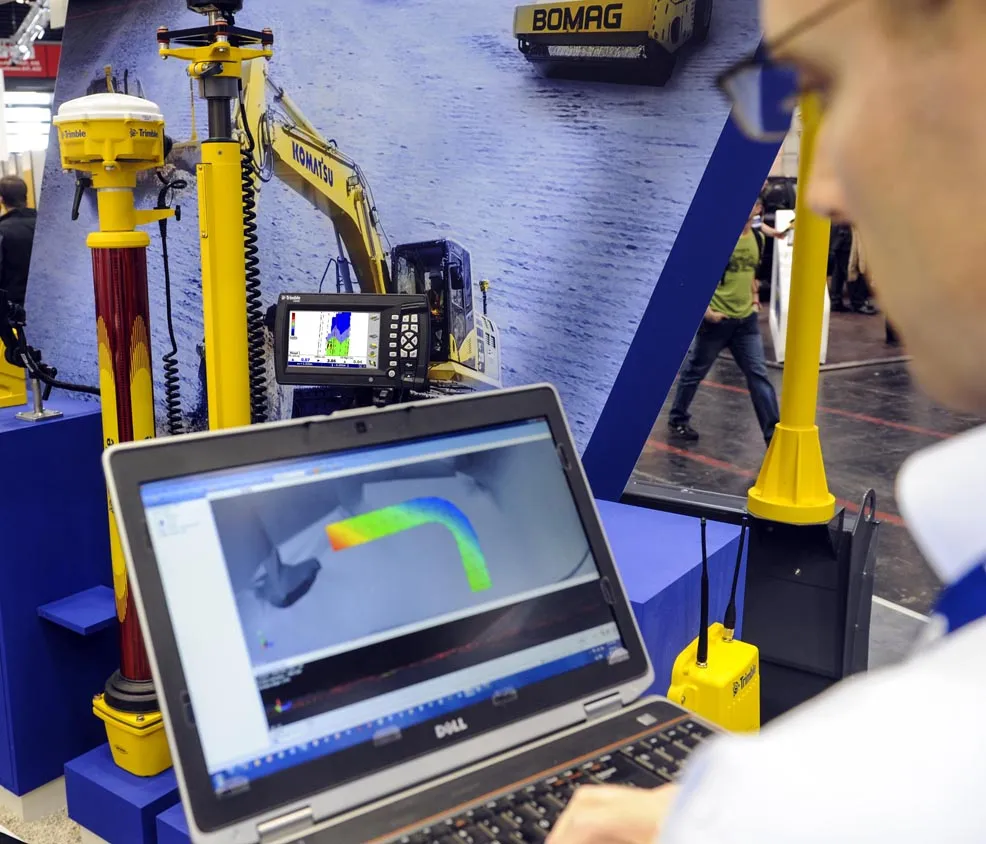

This is essentially a mobile classroom that is currently scheduled to make 23 stops in key markets at or near Topcon distributors, inviting attendees to learn from presentations as well as experience hands-on demonstrations of Topcon machine control technology. The big rig also contains a mobile theater.

At the kickoff event for company employees and local customers, graders, a crawler dozer, an excavator, an ADT, and a tractor-scraper combination were available for demonstrations and operation using the company’s positioning repertoire and cloud-based technology for real-time site management.

For more information and a list of stops, visit %$Linker: