Dutch surveying company Geomaat is capturing millimetre accurate measurements in record times to support a range of highway design, construction and maintenance projects. Using the mobile laser mapping system StreetMapper, and specially developed point cloud software, the company can calculate very accurate cutting, milling and asphalt figures, create as built models and undertake change detection.

“In the past, these types of measurement were undertaken using total stations which was time consuming, and

April 20, 2012

Read time: 2 mins

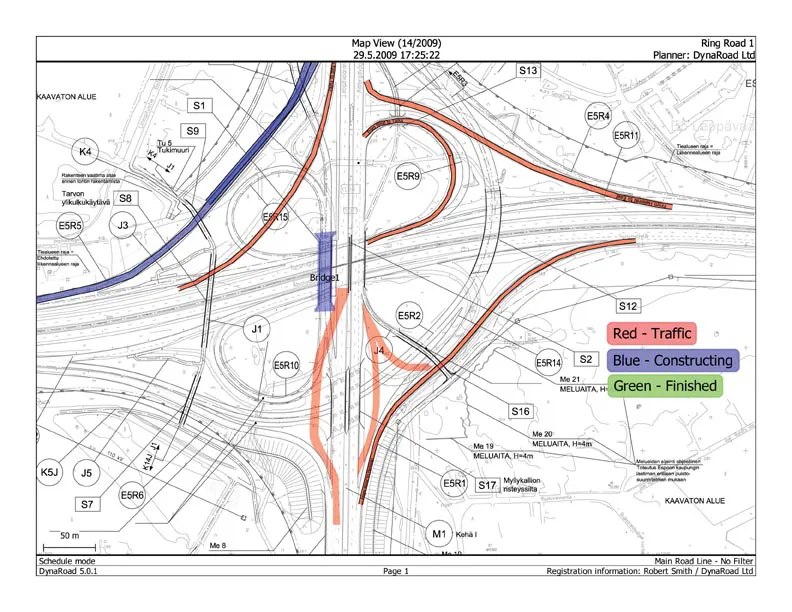

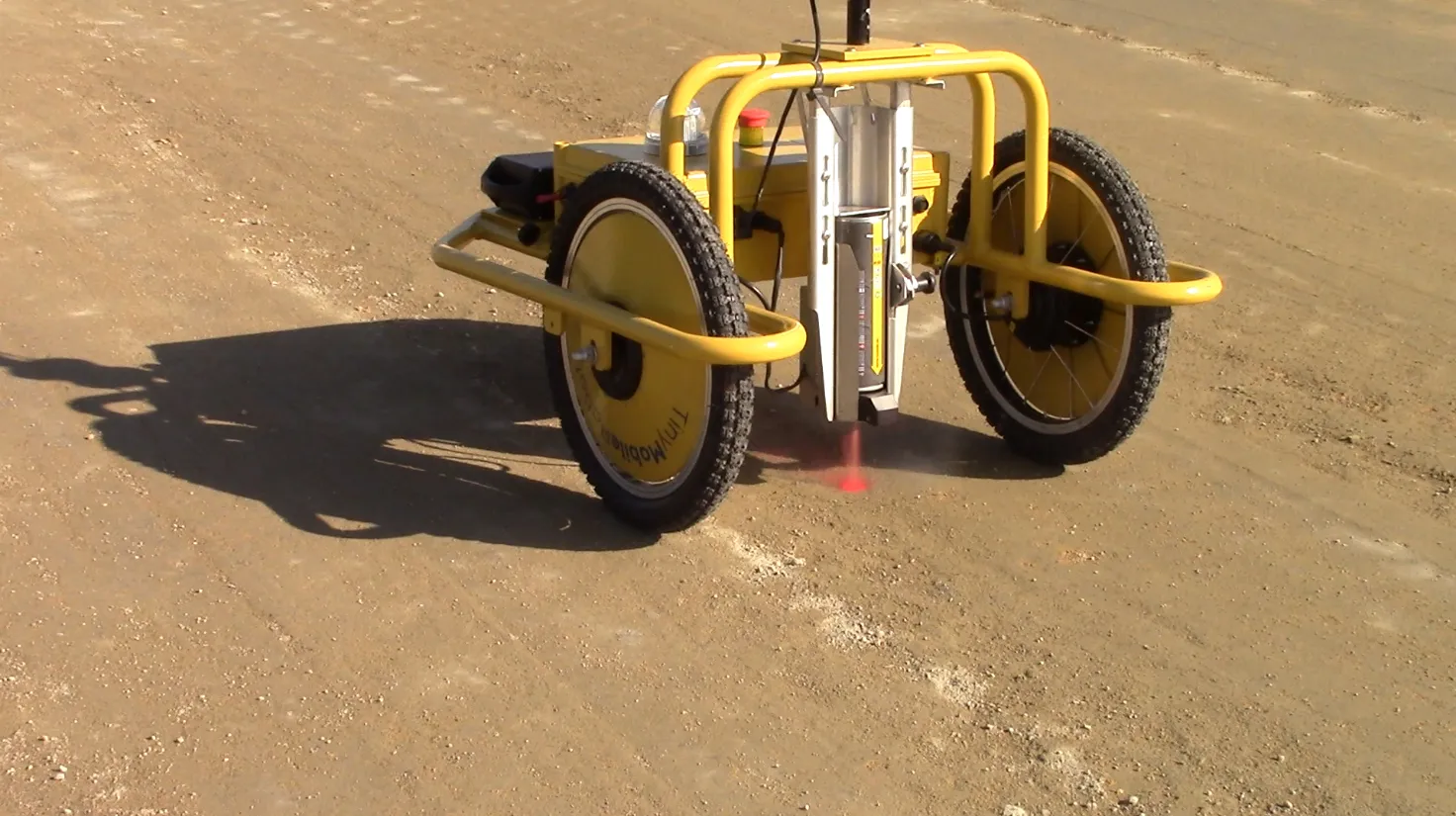

Dutch surveying company 5100 Geomaat is capturing millimetre accurate measurements in record times to support a range of highway design, construction and maintenance projects. Using the mobile laser mapping system StreetMapper, and specially developed point cloud software, the company can calculate very accurate cutting, milling and asphalt figures, create as built models and undertake change detection.

“In the past, these types of measurement were undertaken using total stations which was time consuming, and therefore costly, and had a big impact on other road users,” commented Jolle Jelle de Vries, managing director of Geomaat. “For example a 10km stretch of highway would have taken at least 20 nights to survey, each night requiring extensive traffic management or road closures. The resulting measurements would then have taken about a week to process. Using StreetMapper we can deliver a new design, from start to finish, in less than a week!”

StreetMapper, which Geomaat estimates provides savings of up to 50 per cent for its clients, has been specifically designed for the rapid 3D mapping of highways, runways, railways, infrastructure and buildings. Using vehicle-mounted lasers offering a 360-degree field of view, StreetMapper enables high precision mapping to a range of 300 metres, a capacity of 550,000 measurements per second per sensor and recorded accuracies in independent real world projects of better than 10 millimetres.

Recent projects undertaken by Geomaat in The Netherlands that have benefited from the use of the StreetMapper mobile mapping system include a project to upgrade the A50 between Ewijk and Valburg on behalf of the Rijkswaterstaat, an executive of the Ministry of Infrastructure and Environment, a project to upgrade the runway at Johan Adolf Pengel International Airport and surveying over 500 kilometres of highway in support of LEM Contracts (Lifetime Maintenance). Using StreetMapper, Geomaat is also hoping to work with Municipalities to support the introduction in 2012 of a new BGT (Basic Registration History and Topography) law.

“In the past, these types of measurement were undertaken using total stations which was time consuming, and therefore costly, and had a big impact on other road users,” commented Jolle Jelle de Vries, managing director of Geomaat. “For example a 10km stretch of highway would have taken at least 20 nights to survey, each night requiring extensive traffic management or road closures. The resulting measurements would then have taken about a week to process. Using StreetMapper we can deliver a new design, from start to finish, in less than a week!”

StreetMapper, which Geomaat estimates provides savings of up to 50 per cent for its clients, has been specifically designed for the rapid 3D mapping of highways, runways, railways, infrastructure and buildings. Using vehicle-mounted lasers offering a 360-degree field of view, StreetMapper enables high precision mapping to a range of 300 metres, a capacity of 550,000 measurements per second per sensor and recorded accuracies in independent real world projects of better than 10 millimetres.

Recent projects undertaken by Geomaat in The Netherlands that have benefited from the use of the StreetMapper mobile mapping system include a project to upgrade the A50 between Ewijk and Valburg on behalf of the Rijkswaterstaat, an executive of the Ministry of Infrastructure and Environment, a project to upgrade the runway at Johan Adolf Pengel International Airport and surveying over 500 kilometres of highway in support of LEM Contracts (Lifetime Maintenance). Using StreetMapper, Geomaat is also hoping to work with Municipalities to support the introduction in 2012 of a new BGT (Basic Registration History and Topography) law.