“Bluebeam was founded on the idea that powerful AEC solutions should also be easy to use, capable of delivering the right information at the right time while improving the ability of all project partners to collaborate throughout the lifecycle of an entire project,” said Bluebeam CEO Jon Elliott. “We are incredibly excited to add Project Atlas to our portfolio of solutions to continue delivering on this promise. Project Atlas provides users an entirely new way to visually organise and unify location-based documents and data. This location-based methodology dramatically reduces the time it takes to find critical plans and information, empowering owners, architects, engineers, contractors and specialty contractors to access data in an immediately understandable way that will be especially beneficial in the field."

Project Atlas co-founder and Bluebeam VP of business development and partnerships Todd Wynne said, "By working collaboratively using a visual map of a project, customers can understand projects in a familiar context and break down the barriers that often keep information from getting to the people who need it most."

Software firm acquired by Bluebeam

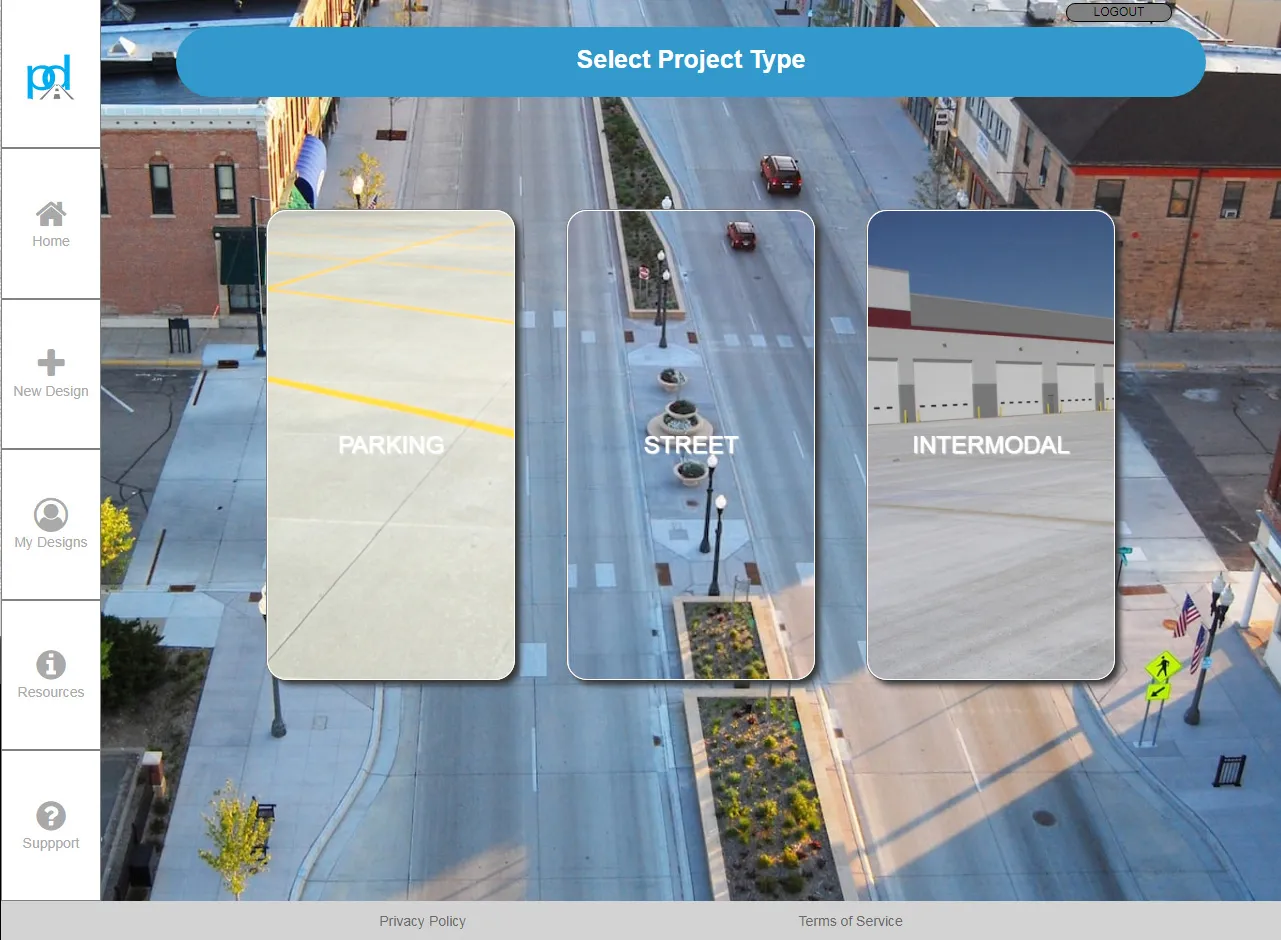

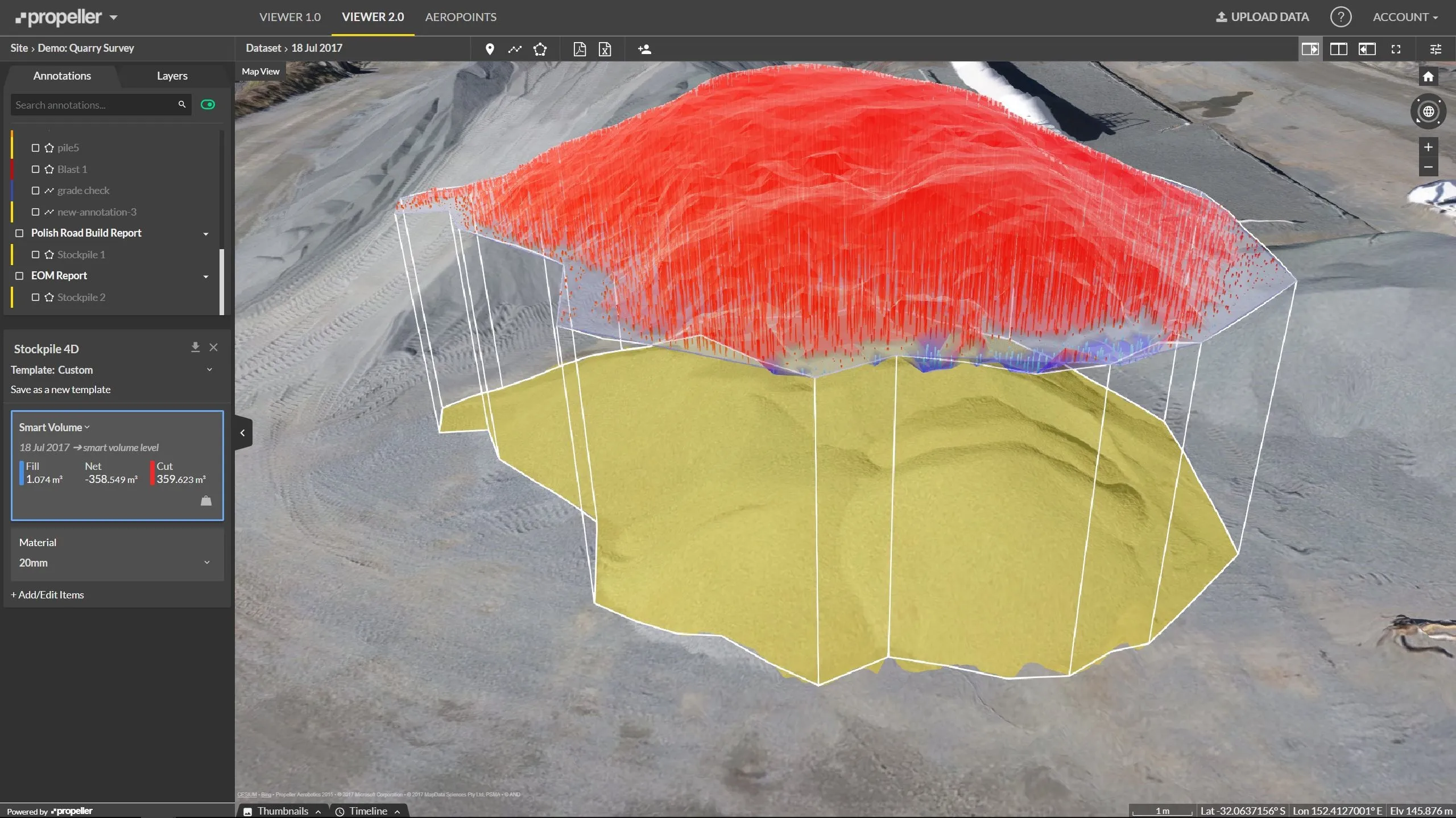

Technology specialist Bluebeam is broadening its portfolio with the acquisition of the privately owned firm Project Atlas. The purchase will expand Bluebeam’s capabilities as Project Atlas developed a digital mapping engine that uses geo-location instead of traditional folder structures to organise and visualise 2D plans and construction data. This location-based orientation allows design and construction professionals to create and search a digital map of their project that contains plans, people, material

June 18, 2018

Read time: 2 mins

Technology specialist Bluebeam is broadening its portfolio with the acquisition of the privately owned firm Project Atlas. The purchase will expand Bluebeam’s capabilities as Project Atlas developed a digital mapping engine that uses geo-location instead of traditional folder structures to organise and visualise 2D plans and construction data. This location-based orientation allows design and construction professionals to create and search a digital map of their project that contains plans, people, material, site photos and drone imagery, within highly detailed layers.