Perhaps the most eye-catching of all of these is for the autonomous compactor and dozer system Trimble is in the process of developing.

Scott Crozier is general manager of Trimble’s general construction division. He said that while this autonomous machine technology is not yet ready for the market, “It may not be as far away as expected.”

Trimble still has a lot of development work to carry out on its autonomous machine control package and there will be other challenges too. He said, “There will be some regulations we’ll have to comply with.”

However the firm is confident that the project will deliver practical solutions and Crozier continued, “It’ll come in gradually.” He added that certain elements of the technology will be brought to market in the near future. Semi-autonomous technology could be on the market by 2020, with autonomous machines then being introduced for certain applications within five years.

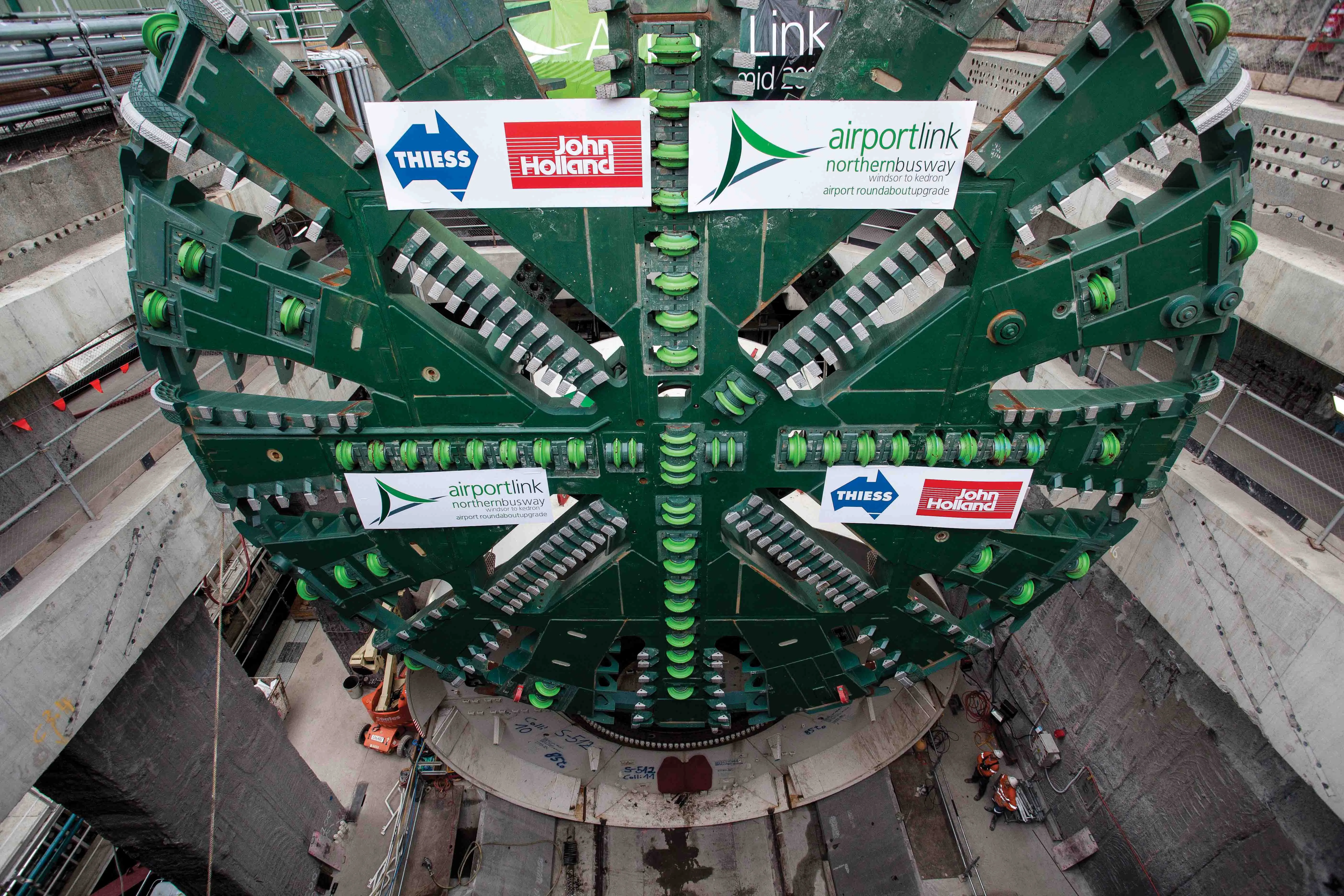

The technology is being aimed at a particular range of duties. Crozier explained that these systems could be used in large greenfield construction sites such as for new airports or for use at landfill sites, where equipment would typically carry out repetitive operations. Geofencing would ensure that the machines would run in controlled areas away from personnel, optimising safety.

Machine autonomy for compactors and dozers being developed by Trimble

Trimble is working on innovative technologies that could revolutionise the construction and aggregates production sectors.

Perhaps the most eye-catching of all of these is for the autonomous compactor and dozer system Trimble is in the process of developing.

Scott Crozier is general manager of Trimble’s general construction division. He said that while this autonomous machine technology is not yet ready for the market, “It may not be as far away as expected.”

December 10, 2018

Read time: 2 mins