Improved efficiency for data communications between construction equipment will be achieved with a new international standard now under development. The Association of Equipment Manufacturers (AEM) is working with the International Organisation for Standardization (ISO) to optimise the flow of data between equipment and project stakeholders. An ISO Working Group, comprised of several AEM members, is in the process of developing a global standard for worksite interoperability.

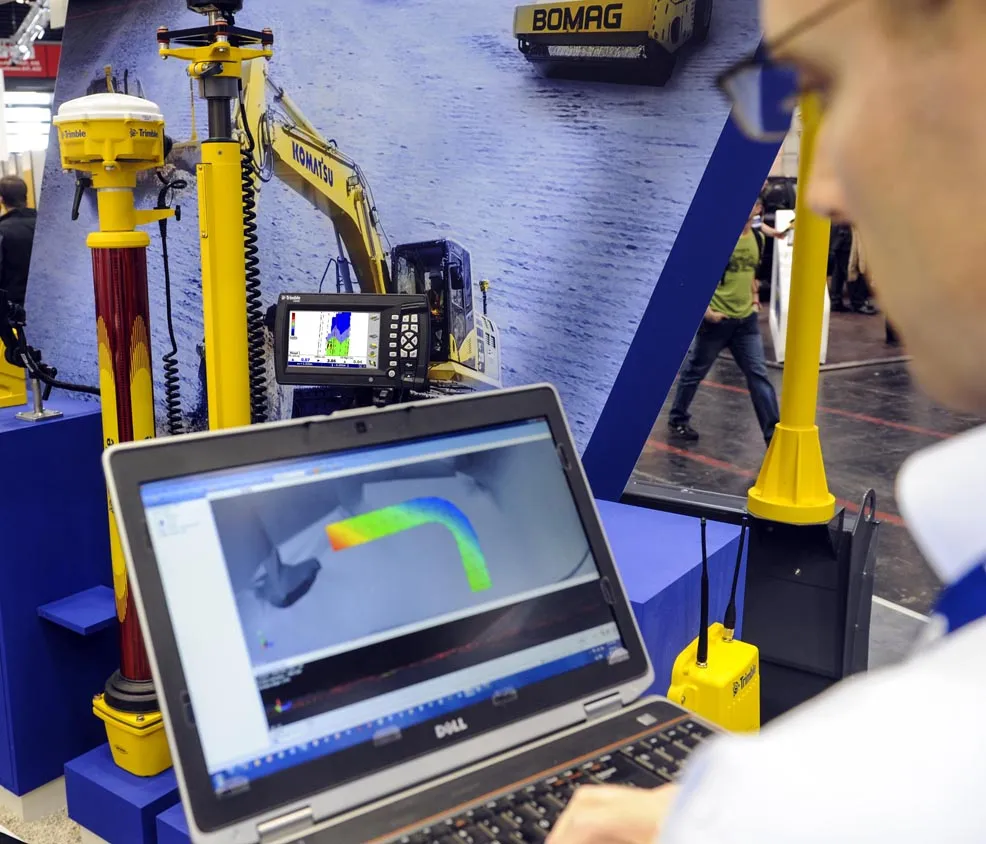

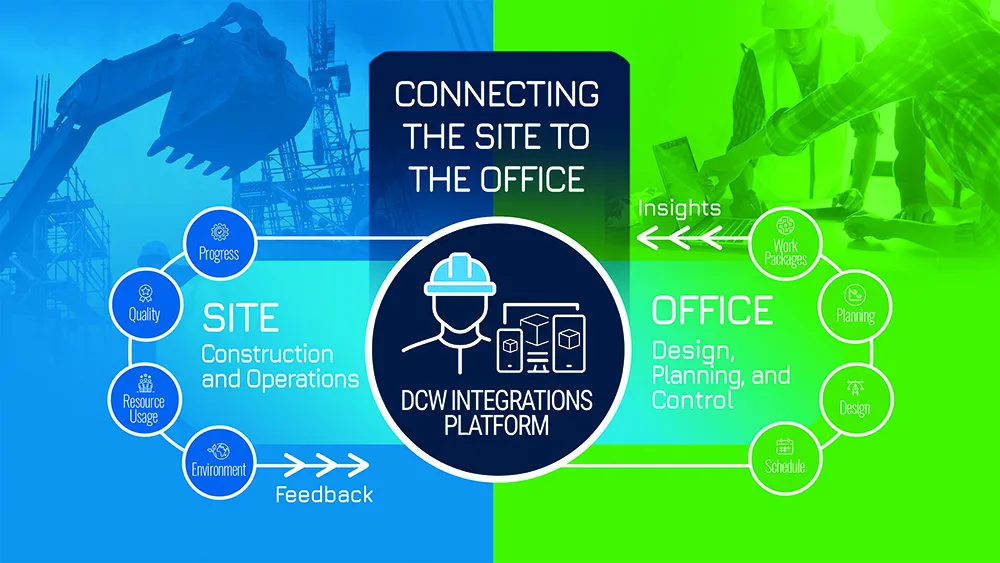

The purpose of this standard is to provide information enabling different providers of machine grade control systems to efficiently interoperate on the same worksite.

“Fleets containing multiple brands, along with general contractors using different systems than their sub-contractors, is the norm on jobsites, if only because not every equipment manufacturer makes every single type of machine or technology that is used,” said Sara Feuling, director of Construction at AEM. “This new standard will normalise data exchange at the interface between earth-moving machinery with grade control systems and the site information system.”

The scope of this standard, formally titled “Worksite Topographical Data Exchange”, initially includes earthwork applications, including roadbuilding and site development. It focuses on onsite radio corrections, digital terrain models, and overall jobsite information. The Working Group is targeting final rollout by the end of 2021. Preliminary details of the standard will be shared at the Tech Experience at CONEXPO-CON/AGG 2020 in Las Vegas.

“New technology in the construction space is one of the most important things we’re doing at CONEXPO-CON/AGG this year,” said Dana Wuesthoff, CONEXPO-CON/AGG show director. “One of the things we’re especially proud to show off is collaborations like this between AEM member companies who would otherwise be competitors.”