More than 200 people were in attendance at the event on Wednesday 20 November 2020. They included South Korea National Assembly figures, the Mayor of Boryeong City, business executives from Bosch, ASI, LG U+ and PoteNit, representatives of government agencies and scholars from various academic institutions.

Concept-X is a comprehensive control solution that can be used to survey worksite topography via 3D drone scanning, establish operational plans based on the topographical data, and operate construction equipment such as excavators and wheeled loaders without human intervention. In short, Concept-X realises the construction site of the future by having all dangerous construction work performed solely by equipment, leaving human personnel free to concentrate on more sophisticated analysis and management tasks.

Although certain individual unmanned technologies have already been introduced in the construction machinery sector, Doosan Infracore’s introduction of unmanned automation technologies to the entire construction site operation process - ranging from surveying to the operations of construction equipment such as excavators and wheeled loaders - is a world first. No one else has done what Doosan Infracore is doing.

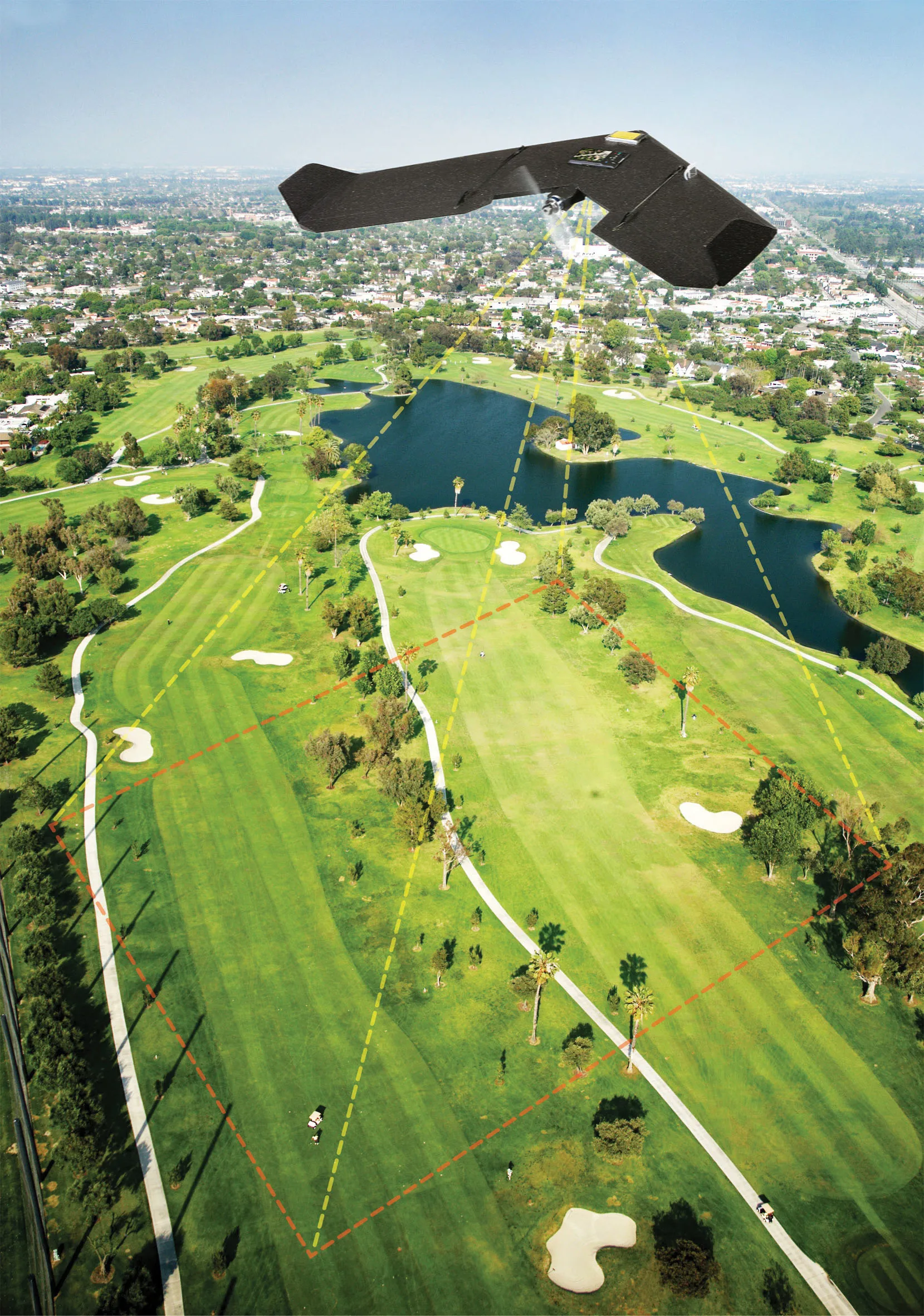

Concept-X comprises a wide range of cutting-edge ‘Fourth Industrial Revolution’ technologies such as image recognition, cognitive/control technologies, autonomous driving technologies, 5G remote control, 3D drone surveys and accurate workload estimation and assignment, together with failure prediction technologies.

The new technologies introduced during the Doosan Infracore demonstration included a technology designed to create three-dimensional worksite maps with drone-surveyed data; a technology enabling construction equipment such as excavators and wheeled loaders to perform optimised unmanned operations according to any site situation; and a technology that makes real-time monitoring of work progress possible through the X-Centre’s comprehensive control solution.

Doosan Infracore asserts that the solution will boost productivity and economic feasibility significantly by reducing the time and costs required for construction equipment operations, while introducing a revolutionary improvement to the issue of construction worksite safety. Crucially, the company plans to commercialise Concept-X by 2025.

Pending its commercialisation, Doosan Infracore will introduce each of the abovementioned technologies - including drone surveying, cutting-edge data analysis, and unmanned construction equipment operations and control - individually as soon as they have been fully verified.

“Concept-X is not just an unmanned technology: Rather, it integrates multiple state-of-the-art technologies that can respond immediately to all and any of the changes that may arise at construction sites simultaneously,” declared Doosan Infracore president & CEO, Dongyoun Sohn. "It will become a human-centred technology that not only brings about remarkable improvements in economics and safety but also creates more jobs in high-tech industries.”

In addition to its independent technology development, Doosan Infracore has pursued various forms of open innovation including collaboration with other companies and schools, as well as investment in start-ups. The company has engaged in industry-academic co-operation with Seoul National University, Yonsei University and Hanyang University in order to develop new technologies related to AI-based construction equipment operations, drone 3D surveying and operational data analysis. In 2018, Doosan Infracore, in partnership with LG U+, introduced 5G-based remote control technology.