DCW’s new monitoring system has evolved from the company’s mission “to enable higher levels of construction project efficiencies through digitally connecting all aspects of a project - the construction ecosystem.”

The firm is jointly backed by Bentley Systems and Topcon Positioning Systems. Its first program was called Constructioneering (which predates DCW) and it was designed to help construction industry professionals achieve better integrations, automated workflows, improved reports and visual representation of the project.

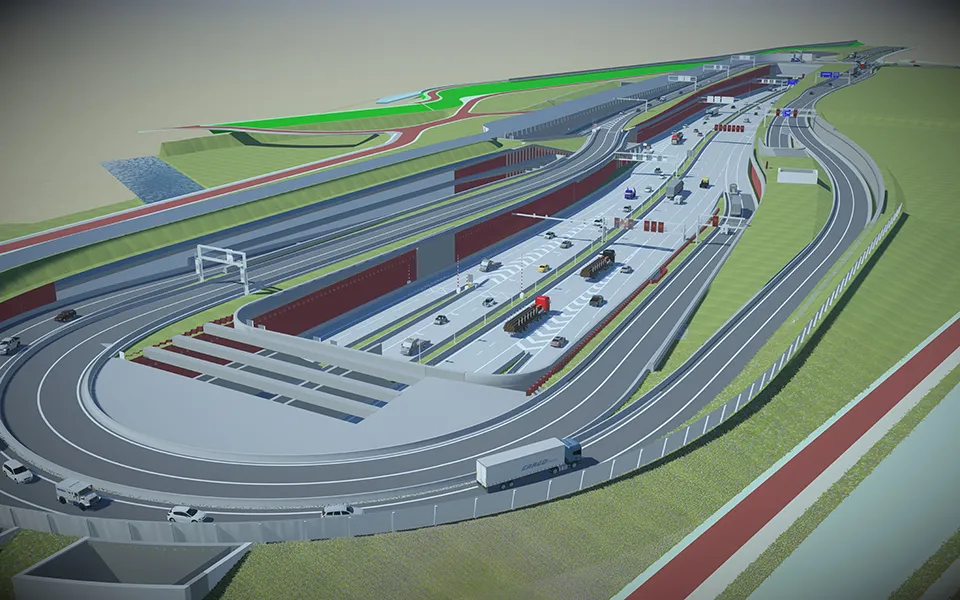

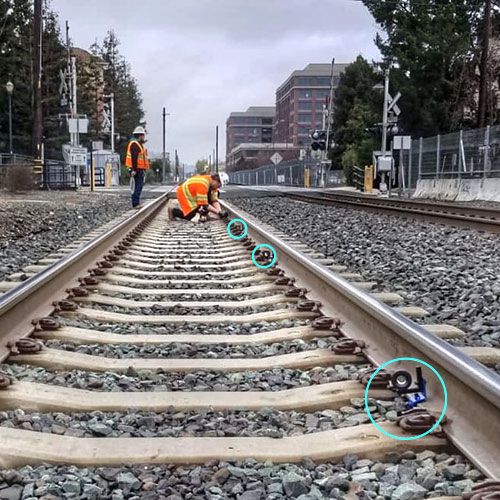

Through its new monitoring system, DCW leverages direct access to Topcon's positioning technology and Bentley's infrastructure IoT technology “while adding the glue that holds it all together … the DCW Integrations Platform.”

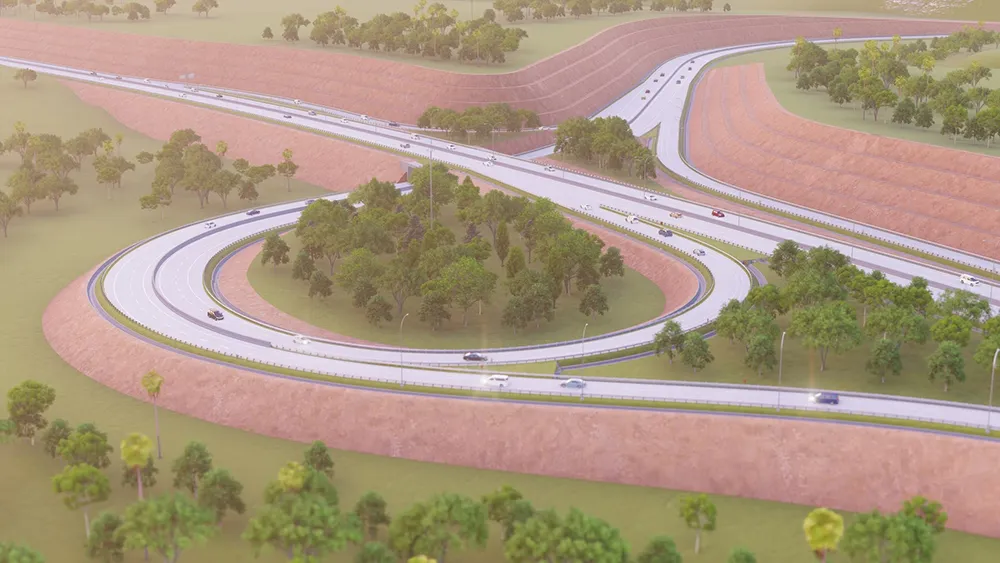

According to DCW, the platform “remains agnostic and open to new, innovative technologies worldwide. There is demand in the construction industry for an integrations platform that ties together a wide range of geotechnical and geopositioning sensor technology with other project activity data sources of a construction project.

“Monitoring a construction site and long-term monitoring of an existing structure's health involves an array of sensors. Fortunately, sensor technology is rapidly switching to IoT-based sensors wherever possible. The DCW Integrations Platform can tie together these otherwise disparate data sources and provide automated workflows with easy access to summary reports and charts.

“It is a vision of DCW that monitoring data, and monitoring technology typically used only to determine slight movement in an at-risk structure, will soon be leveraged to provide essential and timely insights into a construction project's progress. Technology should be connected, and their data used for more than just a simple Delta XYZ. The natural technology innovation cycle is rapidly changing.

“As an agnostic provider of monitoring services and solutions, DCW is open to integrating what the market provides and what our clients already trust.”

If you would like to read more about DCW and its plans for the future, please click here to see .a recent World Highways roundtable interview with its chief executive officer Jason Hallett: https://www.worldhighways.com/video/digital-construction-works-roundtable-interview