Caterpillar is now offering a smart safety system called Cat Detect that is intended to reduce risks on working sites. The package can be installed on new machines in the factory or by dealers, and it can also be retrofitted to existing equipment.

Featuring a new smart camera, the system is designed to warn the operator when personnel are in the working area behind a machine.

While the system can be fitted to all types of machines, it is of particular use on wheeled loaders as they spend so much of their working time reversing, according to product specialist Maryn Grigsby. “It’s looking for people shapes,” she said. “It’ll work on any machine.”

The package has different detection zones, and these provide different levels of alerts to the machine operator. For the moment at least, the system will not stop a machine should there be an obstacle, but this is a possible development for the future for certain applications.

Customers for the system will also be able to benefit from new developments to the package as and when these are available. Grigsby commented, “We’re going to continue to offer updates.”

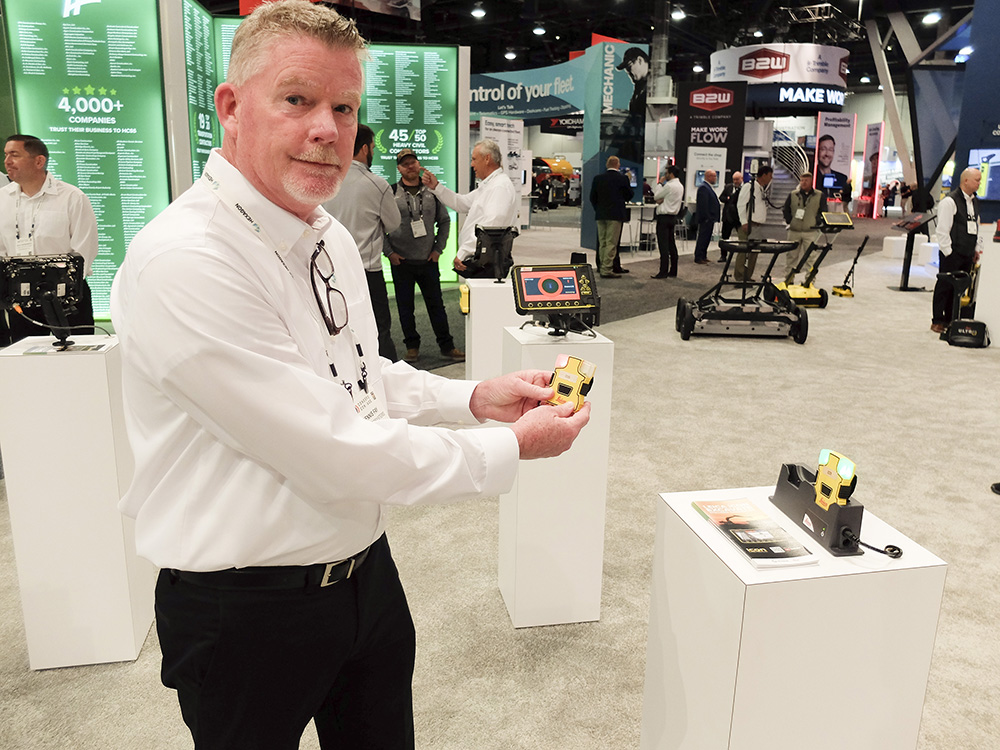

Meanwhile, Leica Geosystems has added further functionality to its site safety package. The firm has partnered with Xwatch to offer a new collision avoidance package that can boost working safety on construction sites.

The package is able to identify personnel in proximity to a working machine, warning an operator and preventing collisions.

Special badges that site personnel wear can be detected by the system, helping ensure their safety on a busy working construction site. The system provides degrees of alert to the machine operator, depending on the proximity of the piece of equipment to the obstruction.

Meanwhile, the system can help reduce risks of an excavator bucket striking buried utilities or overhead cables.

A spokesperson for the firm said, “We can keep adding functions to it.” The package will also track any site incidents and the spokesperson added, “It’ll record all events: near misses and hits and things like that.”