US-based BedRock Software has announced the release of a new version of its AggFlow software package that adds the capability to simulate the operation of mobile crushing and screening plant. The company has initially worked with Powerscreen's line of crushing and screening equipment but other manufacturers' data will be added. "As we build our track-mounted data library this will be an important and revolutionary development for the industry," said BedRock president Bryan Lewis.

The AggFlow system for fix

July 16, 2012

Read time: 2 mins

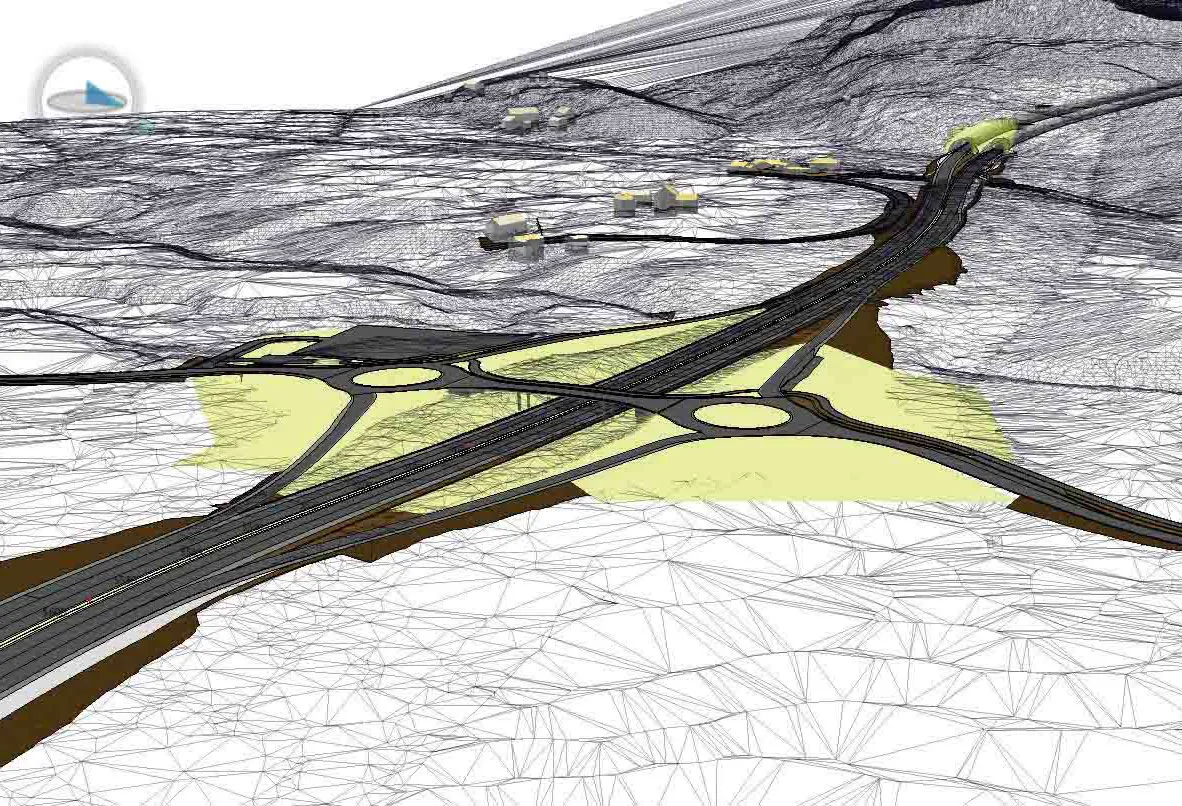

US-based 1412 Bedrock Software has announced the release of a new version of its 153 Aggflow software package that adds the capability to simulate the operation of mobile crushing and screening plant.

The company has initially worked with2991 Powerscreen's line of crushing and screening equipment but other manufacturers' data will be added. "As we build our track-mounted data library this will be an important and revolutionary development for the industry," said BedRock president Bryan Lewis.

The AggFlow system for fixed plant is already used by aggregate producers in over 60 countries worldwide, according to Lewis, but the updated version will give users the benefit of being able to calculate mass aggregate and water balances flowing through a plant simulation using stationary and mobile equipment.

AggFlow simulations are said to help improve profitability by identifying inefficiencies and bottlenecks; by accurately assessing the impact of proposed changes or new equipment before they are made; and by reducing plant down-time and production errors. AggFlow can also be used to track and reduce emissions and fuel consumption by refining overall plant efficiency.

Users can select from the pre-populated equipment data library or install their own equipment models in the program using the generic equipment application. Nonetheless, BedRock is constantly adding to the AggFlow data library and will add equipment upon request, although the program currently provides calculations for more than 2,500 models of aggregate crushing, screening and washing equipment.

The company has initially worked with

The AggFlow system for fixed plant is already used by aggregate producers in over 60 countries worldwide, according to Lewis, but the updated version will give users the benefit of being able to calculate mass aggregate and water balances flowing through a plant simulation using stationary and mobile equipment.

AggFlow simulations are said to help improve profitability by identifying inefficiencies and bottlenecks; by accurately assessing the impact of proposed changes or new equipment before they are made; and by reducing plant down-time and production errors. AggFlow can also be used to track and reduce emissions and fuel consumption by refining overall plant efficiency.

Users can select from the pre-populated equipment data library or install their own equipment models in the program using the generic equipment application. Nonetheless, BedRock is constantly adding to the AggFlow data library and will add equipment upon request, although the program currently provides calculations for more than 2,500 models of aggregate crushing, screening and washing equipment.