In August 2018, a 210m section of the Morandi Bridge in Genoa Italy suddenly collapsed. Although the cause was never officially determined, corrosion had affected the bridge’s structure. Italferr was selected to design an emergency replacement for the 1,182m viaduct over the Polcevera River which is part of a key roadway that links Italy and France and is a main access point to a nearby airport. Consequently, rebuilding it as quickly as possible was critical for the city’s long-term economic and cultural health—and construction would need to begin as the design progressed.

Italferr faced the challenge of completing the design of the €202 million project in only three months—extraordinarily fast for a project of this size and complexity. It also had to create a simple design while incorporating new Italian safety standards for the cross-section of the deck and the curvature radii of the junctions and entrances. Lastly, the project team needed to design and build the bridge on the same footprint as the previous one, with reinforced concrete piers positioned 50-100m apart. Each of these piers has been designed with a continuous cross-section for their entire height.

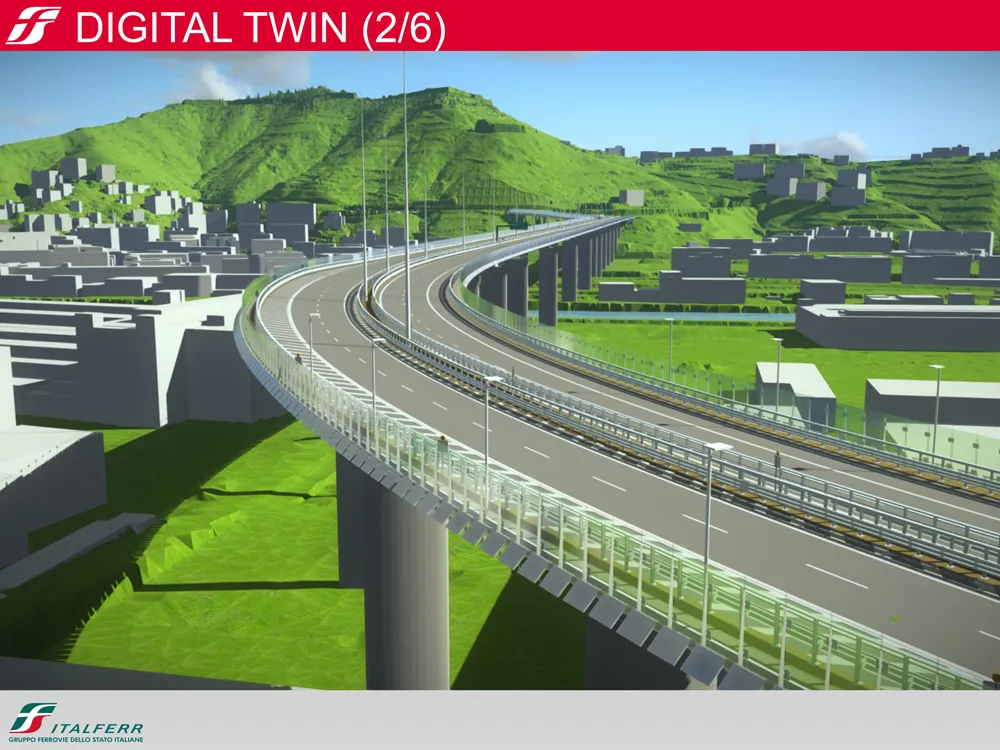

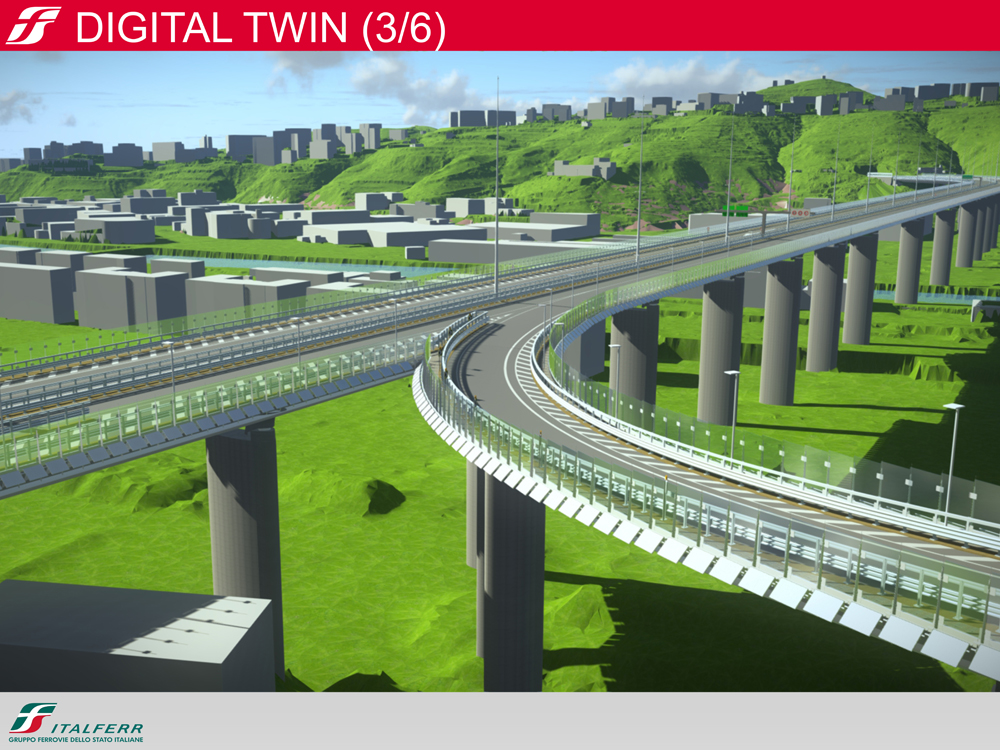

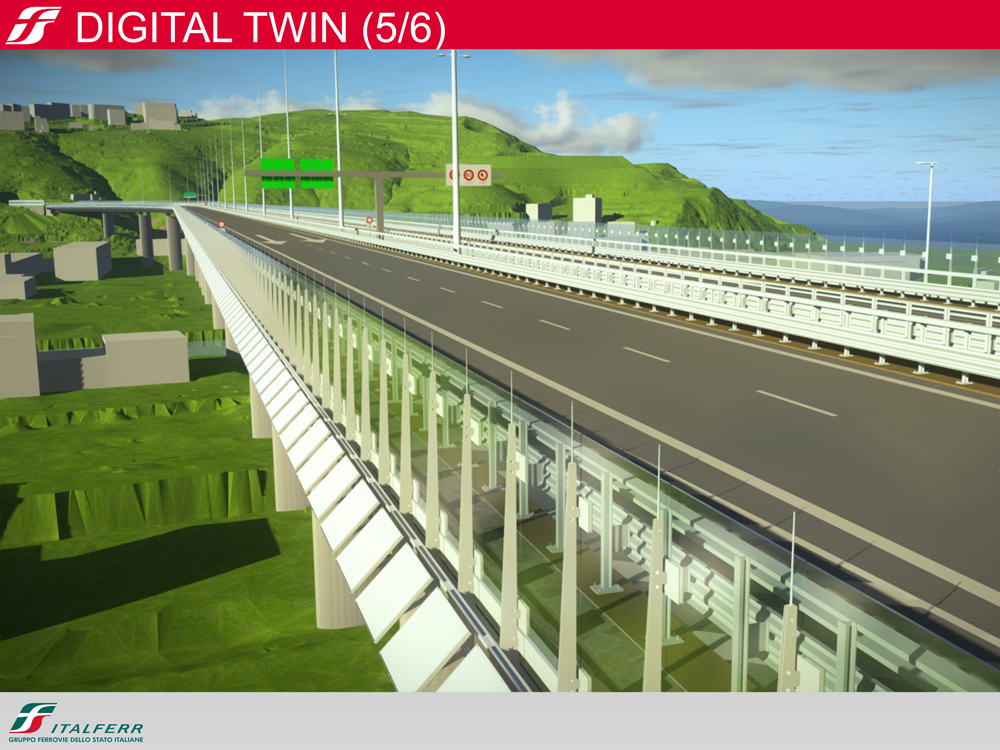

It was determined that the main deck should feature a continuous 1,067m girder with 14 50m and three 100m steel-concrete spans. The Polcevera Viaduct (now known as the Viaduct San Giorgio) would also include one 41m steel-concrete span approaching the west shoulder, one 26m steel-concrete span approaching the east shoulder, and a 110m steel-concrete ramp with three spans connected structurally to the deck. Various important technological features needed to be incorporated throughout the structure, including dehumidifiers and a solar generation plant, to enhance the bridge’s aesthetics, ensure road traffic safety, improve energy efficiency, and maximise durability.

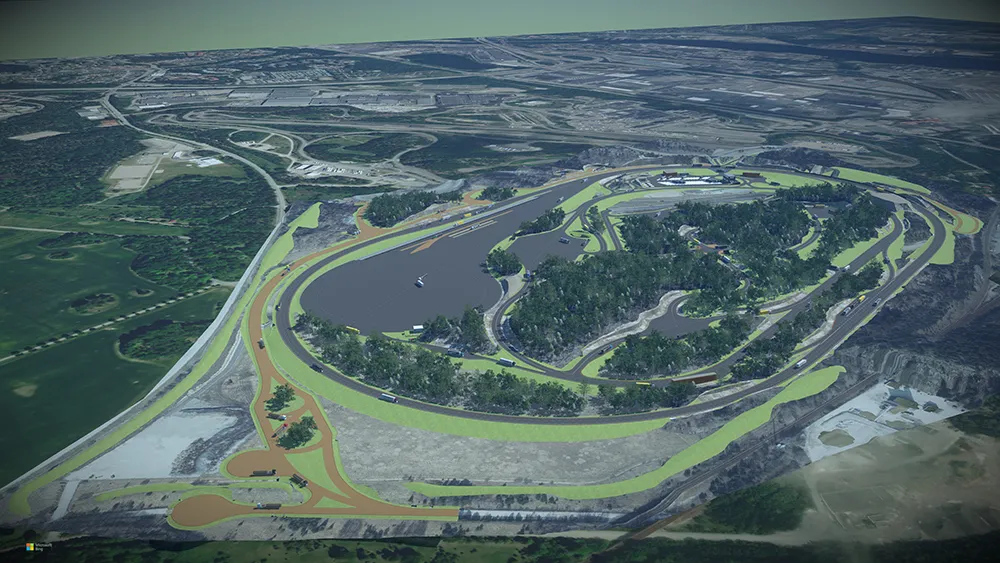

To ensure the accuracy of the design while staying on schedule, Italferr used Bentley’s BIM methodology and created a digital twin of the viaduct to streamline workflows throughout the design phase. “While we were completing our design, the construction team was starting to demolish and build piles and foundations,” said Stefano Casula, structural engineer and BIM expert with Italferr. “We had to catch any mistakes and interferences as soon as possible.” To achieve this goal, Italferr incorporated detailed information for construction and operation into the model, as there was little time to significantly alter the model after the design phase. The organisation also established an open, connected data environment based on Bentley software to promote collaboration among the multidiscipline project team and ensure a single source of truth.

Leveraging BIM and creating a digital workflow with Bentley applications allowed Italferr to visualise the design with a much higher degree of quality and speed than traditional 2D designs. Because of Italferr’s work with 4Dvisualisation, the completed bridge will increase the flow of goods and services in and out of Genoa compared to the previous design. Though the collapse caused nearly two years of economic disruption, Italferr’s work has helped to restore the important transitway, and sets up the city for continued cultural and economic growth.

Read more about this project here.

Sponsored content produced in association with Bentley Systems