While many of the new technologies have been developed by specialist suppliers, many of the original equipment manufacturers (OEMs) are also introducing their own solutions. These can help boost working efficiency as well as site safety for the industry.

The package can supply data on materials from the mixing plant through truck distribution and also on parameters for the paver and compaction.

Should a paver fail onsite, a warning is sent to the mix plant for example, so that truck loads can be stopped and costly material wastage minimised. Similarly, the paver operator will know when trucks will arrive with asphalt for paving.

Useful information includes comparing theoretical asphalt tonnage supplied with actual tonnage used. If the theoretical quantities match the actual tonnages used, this highlights paving efficiency. But if there is a large disparity, the paver operator realises that the screed needs adjustment.

The sophisticated digitalisation package also allows users to reduce CO2 emissions as it helps to minimise energy use.

Komatsu is offering Smart Construction 3D Machine Guidance kit for a broad range of standard Komatsu machines as well as mixed fleets. The 3D Machine Guidance kit provides an accessible way to add 2D and 3D machine guidance to any crawler or wheeled excavator from 13-120tonnes.

The kit can be customised with options such as a tilt bucket and couplers kit, a two-piece boom kit, a super long front kit, and a SATEL radio kit. A 3D safety zone feature has been integrated into the system, allowing customers to generate avoidance zones. The feature alerts operators when they are near hazards such as powerlines, underground utilities or public roads.

The 3D Machine Guidance system’s automatic file conversion is compatible with common design file formats. This ensures integration with existing 3D systems from different manufacturers.

In addition, the 3D Machine Guidance kit has an integrated payload meter option for Komatsu machines. This feature allows for dynamic material weighing, boosting productivity by ensuring trucks are loaded optimally.

The kit is also integrated into the Smart Construction suite as a first step towards optimising earthmoving. It automatically collects terrain and payload data, which can be visualised and analysed using Smart Construction solutions.

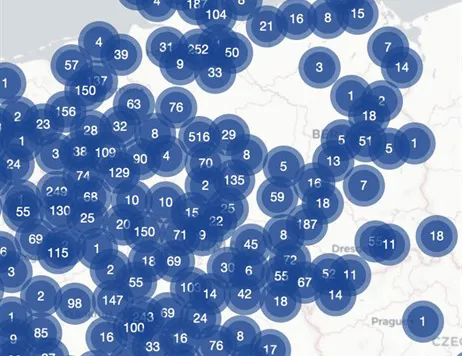

Volvo CE says that its Connected Map provides visibility of the job site by giving a real-time visual overview of the position of every machine, vehicle and visitor The intelligent positioning service can be accessed by all site personnel, both in the machine (via Volvo Co-Pilot or an Android/iOS device) and in the office (via the Office portal).

Connected Map can display site features and landmarks, including roads to help operators navigate the site, loading zones, unloading zones, speed zones and restricted areas. Points of interest such as offices, workshops, and service stations can also be visualised. Single-lane (narrow road) sections can be defined as warning the operator if another machine is approaching in a single-lane section, helping to avoid traffic jams.

Connected Map users also stay informed about the location of machines, due to Connected Map's search functionality, which will search and find users or machines in real-time, with the machine's last position visible for 30 days. Away from the office, Connected Map makes it easier for the operator to familiarise themselves with the site and know where everyone is, boosting safety.